5.

ASSEMBLING

ADJUSTMENT

PROCEDURES

[]]

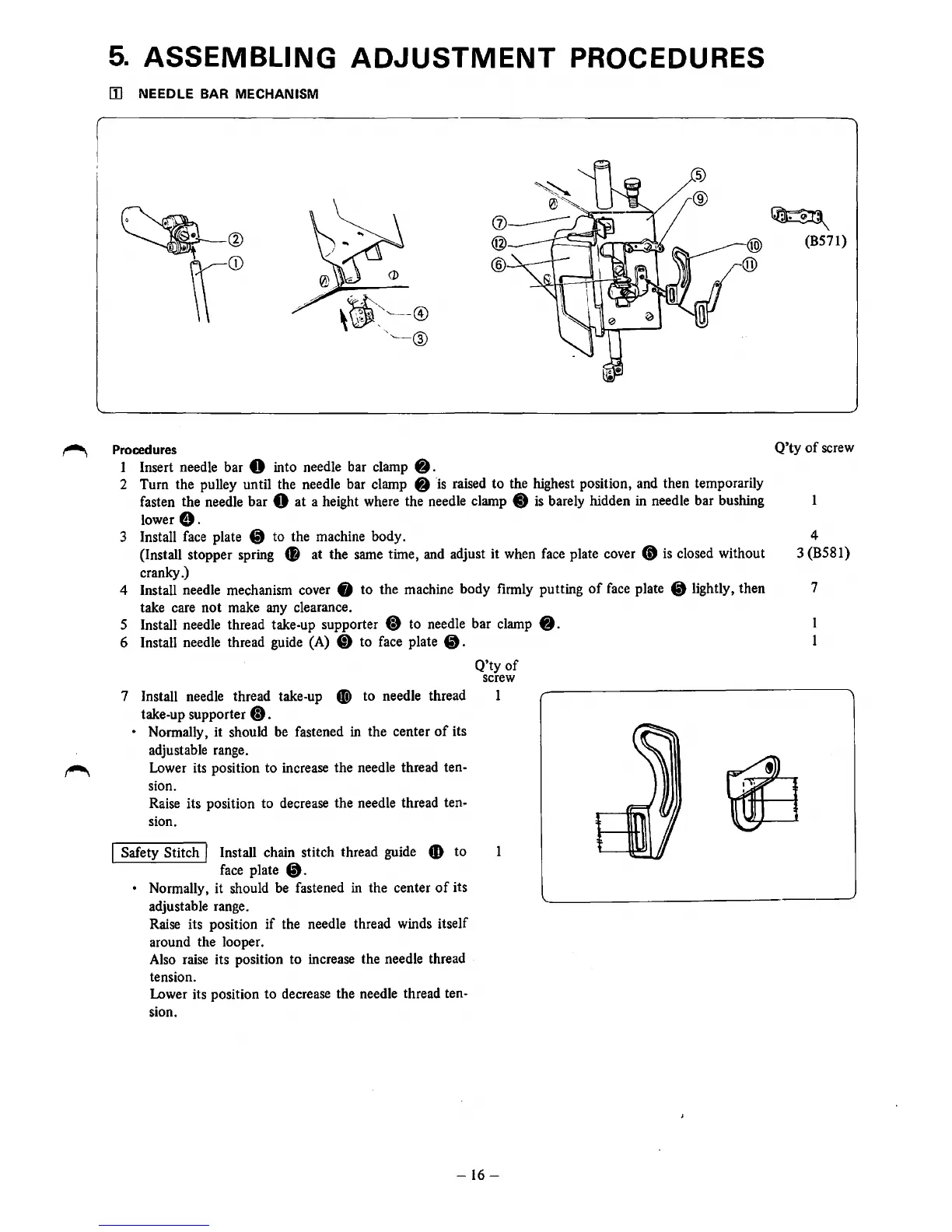

NEEDLE BAR MECHANISM

~

@)

(B571)

@

Procedures

1 Insert needle bar 0 into needle bar clamp 8 .

2 Turn the pulley until the needle bar clamp 8 is raised

to

the highest position, and then temporarily

fasten the needle bar

0 at a height where the needle clamp 0 is barely hidden in needle bar bushing

lower

e.

3 Install face plate 8 to the machine body.

(Install stopper spring

..

at the same time, and adjust it when face plate cover 8 is closed without

cranky.)

4 Install needle mechanism cover 8

to

the machine body firmly putting

of

face plate

CD

lightly, then

take care

not

make any clearance.

5 Install needle thread take-up supporter 0

to

needle bar clamp

8.

6 Install needle thread guide (A)

0)

to

face plate

8.

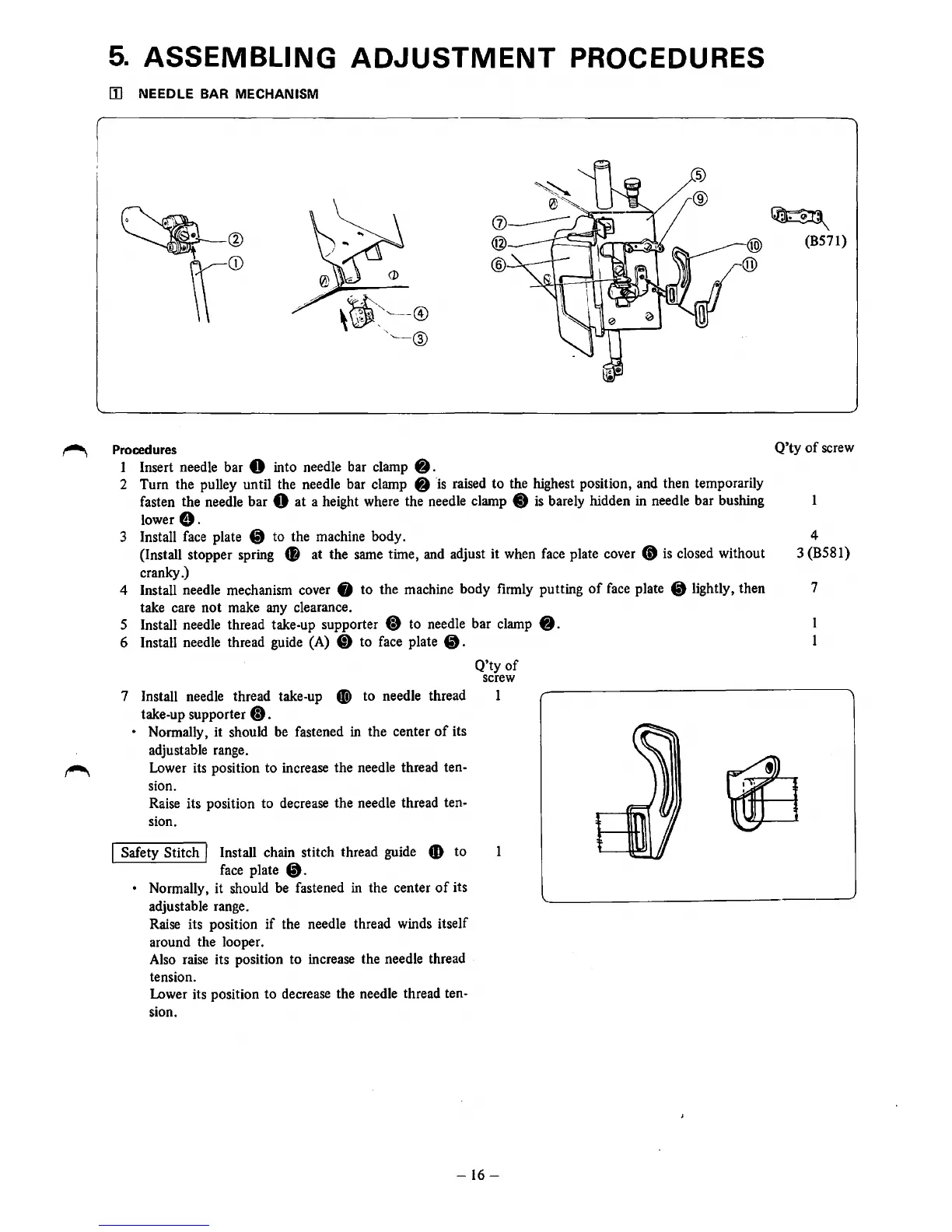

7 Install needle thread take-up

f.D)

to needle thread

take-up supporter

0 .

• Normally, it should be fastened in the center

of

its

adjustable range.

,-......

Lower its position

to

increase the needle thread ten-

sion.

Raise its position to decrease the needle thread

ten-

sion.

I Safety Stitch I Install chain stitch thread guide m

to

face plate

CD.

• Normally, it should be fastened in the center

of

its

adjustable range.

Raise its position

if

the needle thread winds itself

around the looper.

Also raise its position to increase the needle thread

tension.

Lower its position to decrease the needle thread ten-

sion.

Q'ty

of

screw

-16-

Q'ty

of

screw

4

3 (B581)

7

Loading...

Loading...