Procedures

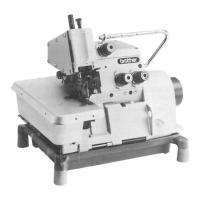

Temporarily fasten double chain stitch looper holder 0

on longitudinal feed shaft 8

2 Install double chain stitch looper 0 by inserting it

all

the way into double chain stitch looper holder

0.

The

inclination

of

the looper depends on the screw recess.

3

I~stall

double chain stitch needle into needle clamp.

Ill The below items

of

8

and

(i) should be taken simul-

taneously.

4

In

case

of

standard specifications, make

an

adjustment

so

that the distance between the looper point and the

center

of

needle

is

1.5mm when double chain stitch

looper comes to the leftmost position. In

case

of

high-

lift specifications, that distance

is

1.3

mm.

(Sidewise potioning)

5 Position the looper

so

that, when the looper point

is

in

line with the needle center on the needle's upward travel,

the looper point will

be

at about 0 to 0.05 mm from

needle, and then fasten double chain stitch looper holder.

(Longitudinal positioning)

*

When

stitch-skips occur, adjust it that the looper point

will hit needle about

0.05 to 0.1

mm

deep.

6 Install double chain stitch needle guard (F) 8 to that

of

(B) (i) in order to make clearance about 0.3 to

O.Smm.

7 Temporarily fasten double chain stitch needle guard (B)

to needle plate support bracket.

8 Match the looper point with the needle center on the

needle's upward travel, hold double chain stitch needle

guard (B) in contact with the needle, adjust the clearance

between the looper point and the needle

to

0

to

0.05 mm,

and fasten double chain stitch needle guard

(B)

securely.

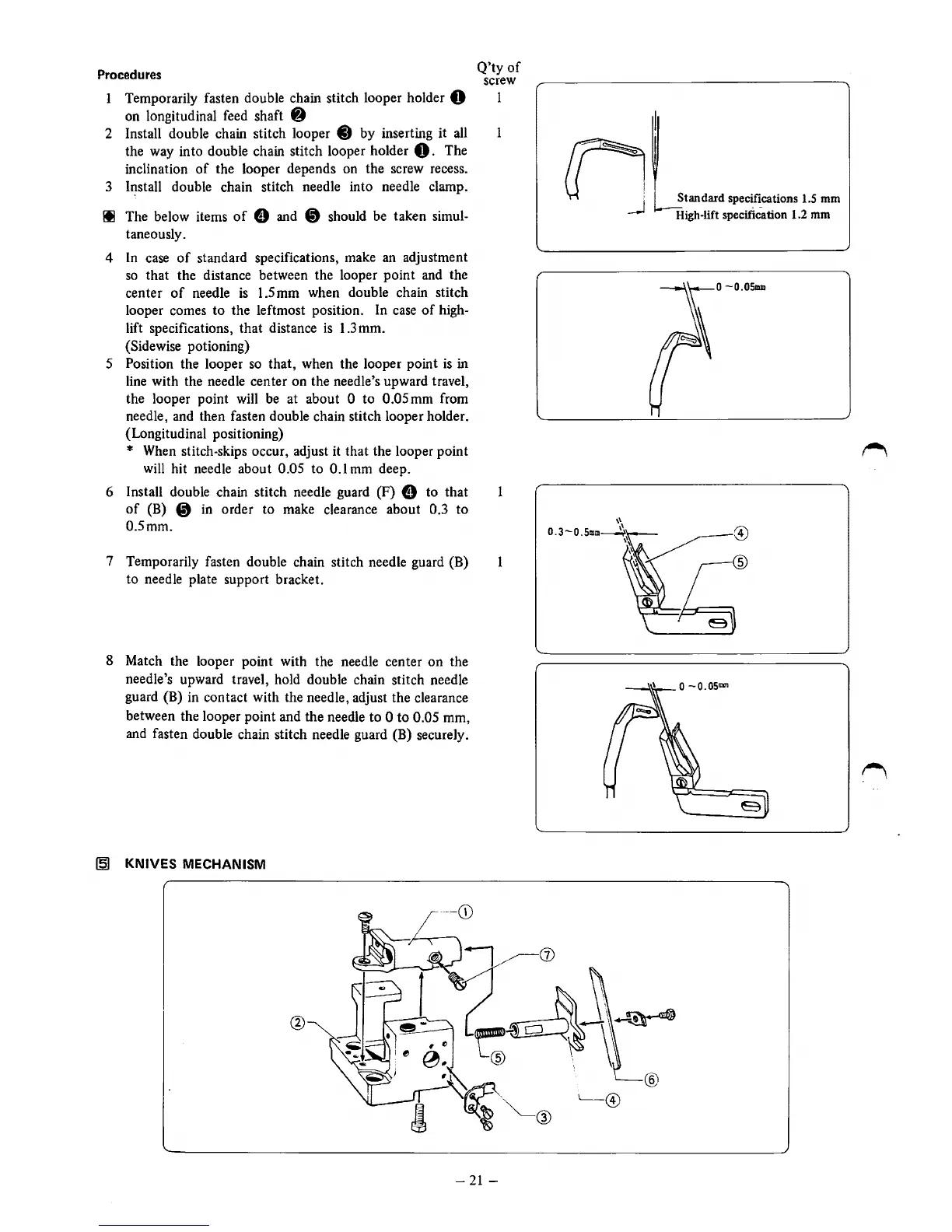

~

KNIVES MECHANISM

Q'ty

of

screw

1

-21-

®

L__®

Loading...

Loading...