Procedures

Q'ty

of

screw

,-------------------------------------------------------~

~

J 0.3-0.SIIIID

.z::wmmm

1

GJ$~~~~~~~~~w~w~wi="

1

==1.=i0tmm

for thin

materJs

.ru;gi~~)&d?ff&

.

~

1.3 mm for medium materials

CD

1.5 mm for. thick materials

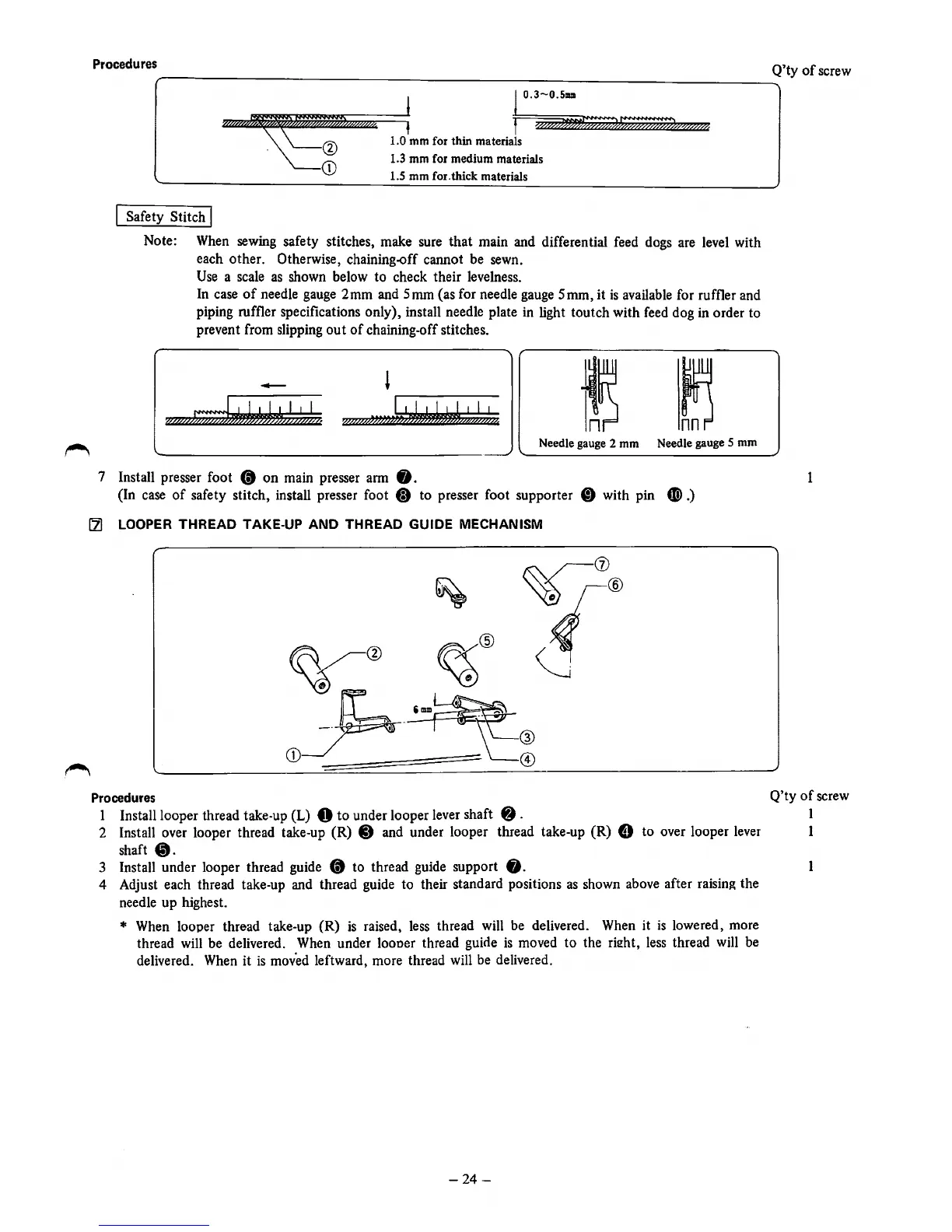

I Safety Stitch I

Note:

When

sewing safety stitches, make sure

that

main and differential feed dogs are level with

each other. Otherwise, chaining-off cannot be sewn.

Use

a scale

as

shown below to check their levelness.

In case

of

needle gauge 2mm and Smm (as for needle gauge Smm, it

is

available for ruffler and

piping ruffler specifications only), install needle plate

in

light toutch with feed dog

in

order to

prevent from slipping

out

of

chaining-off stitches.

l

mm~,....-4-~-~-z-L-L-L

Needle gauge 2 mm Needle gauge 5 mm

7 Install presser foot

(t

on main presser arm

•.

(In case

of

safety stitch, install presser foot 0 to presser foot supporter

0)

with pin

~

.)

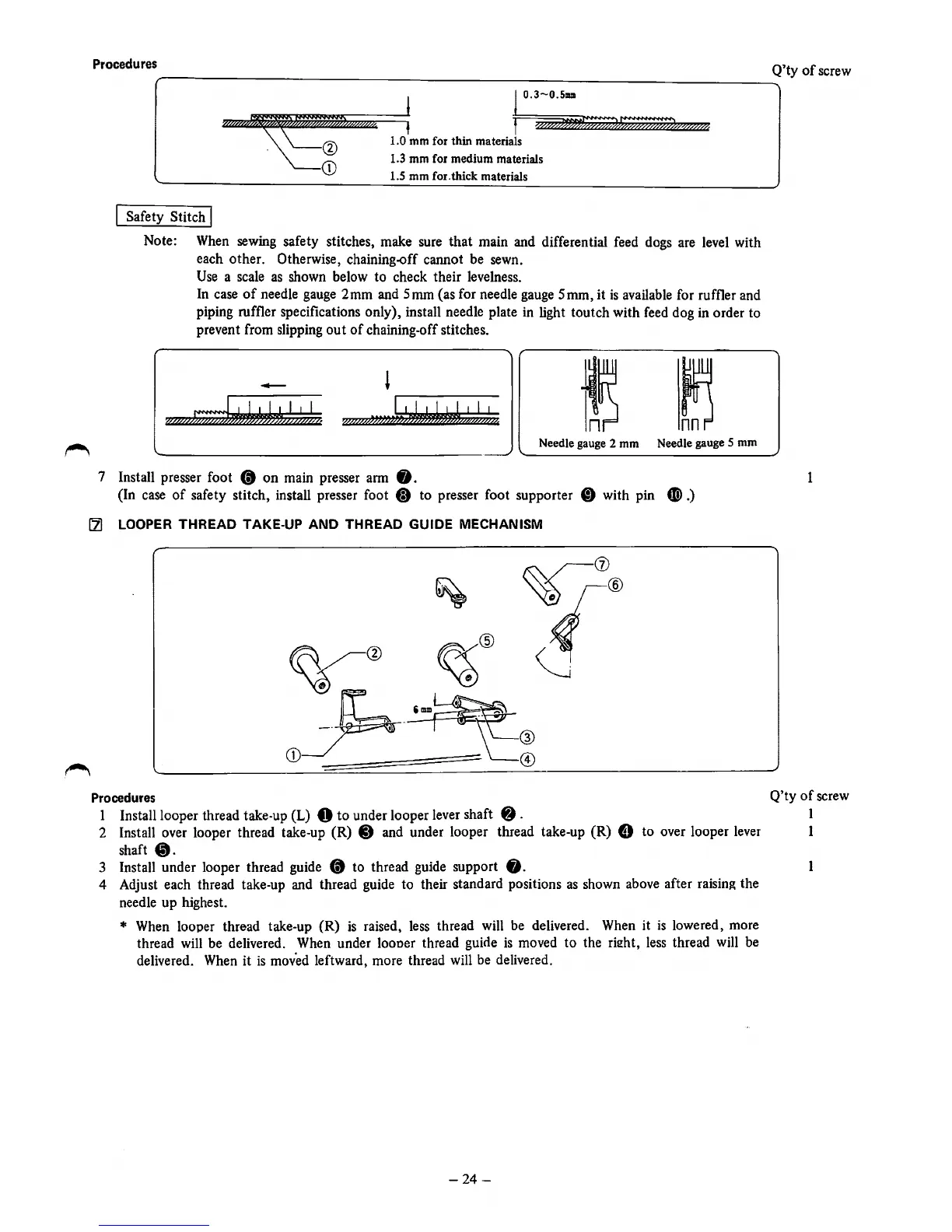

1ZJ

LOOPER

THREAD TAKE-UP AND THREAD GUIDE MECHANISM

Procedures

1 Install looper thread take-up (L) 0

to

under looper lever shaft

8.

2 Install over looper thread take-up (R) C) and under looper thread take-up (R) 8 to over looper lever

shaft

•.

3 Install under looper thread guide

(t

to thread guide support

•.

4 Adjust each thread take-up and thread guide to their standard positions

as

shown above after raising the

needle up highest.

* When looper thread take-up (R)

is

raised, less thread will be delivered. When it

is

lowered, more

thread will be delivered. When under loooer thread guide

is

moved to the rieht,

less

thread will be

delivered.

When

it

is

moved leftward, more thread will be delivered.

-24-

Q'ty

of

screw

1

1

Loading...

Loading...