Adjusting the needle and rotary hook timing

1

Set the stitch length dial to the actual length of the

stitches to be sewn.

Standard stitch length

Specifications Stitch length dial

-T[]F 2

-[][]3 2

-405, -407 3

2

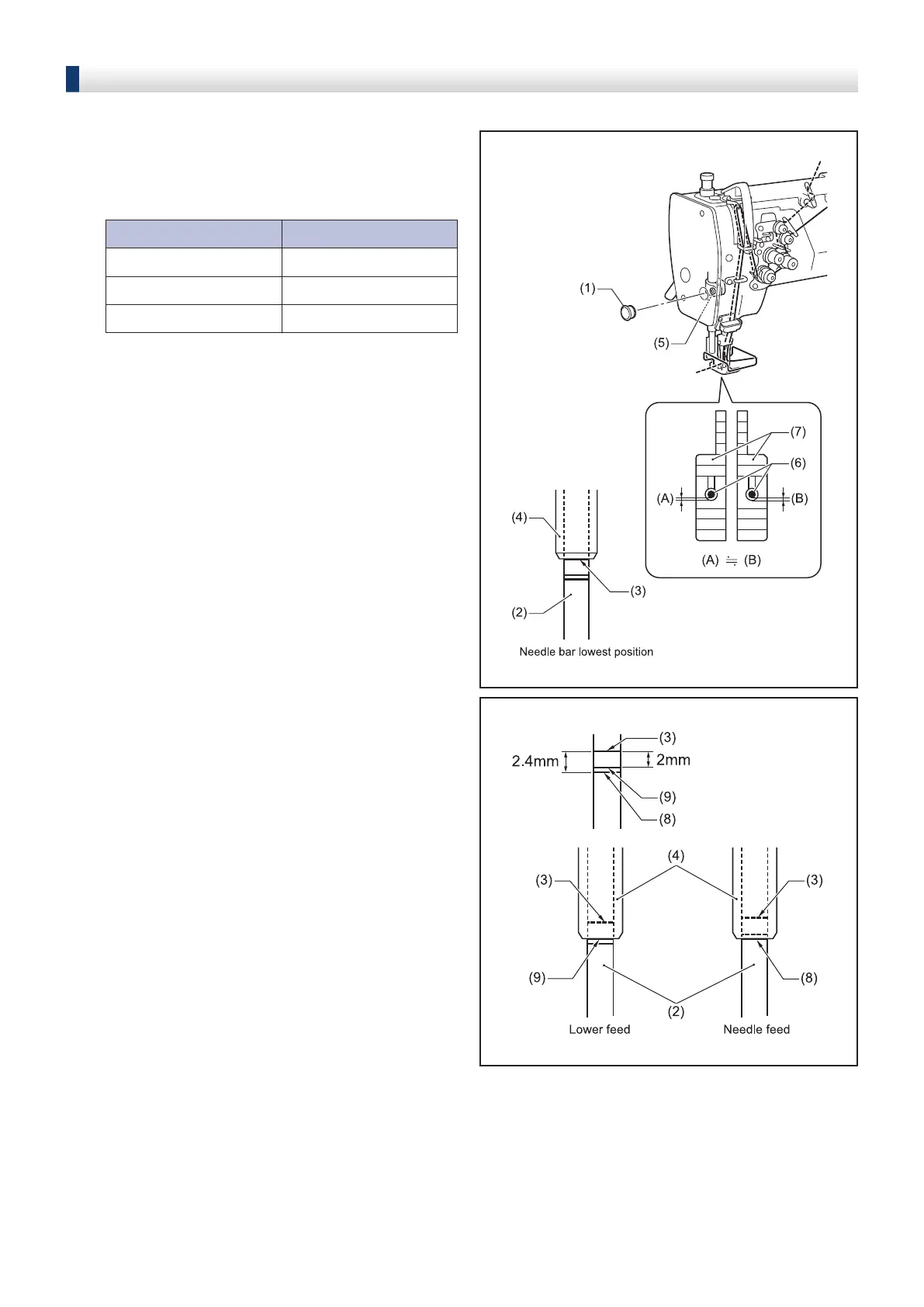

Remove the rubber cap (1).

3

Loosen the screw (5) and move the needle bar (2)

up or down to adjust so that the top reference line

(3) on the needle bar (2) is aligned with the bottom

edge of the needle bar bracket (4) when the

needle bar (2) is at its lowest position. Be careful

not to turn the needle bar (2) at this time.

4

Securely tighten the screw (5).

5

At this time, the gaps (A) and (B) between the

needle (6) and the front of the feed dog (7) should

be about the same as each other.

6

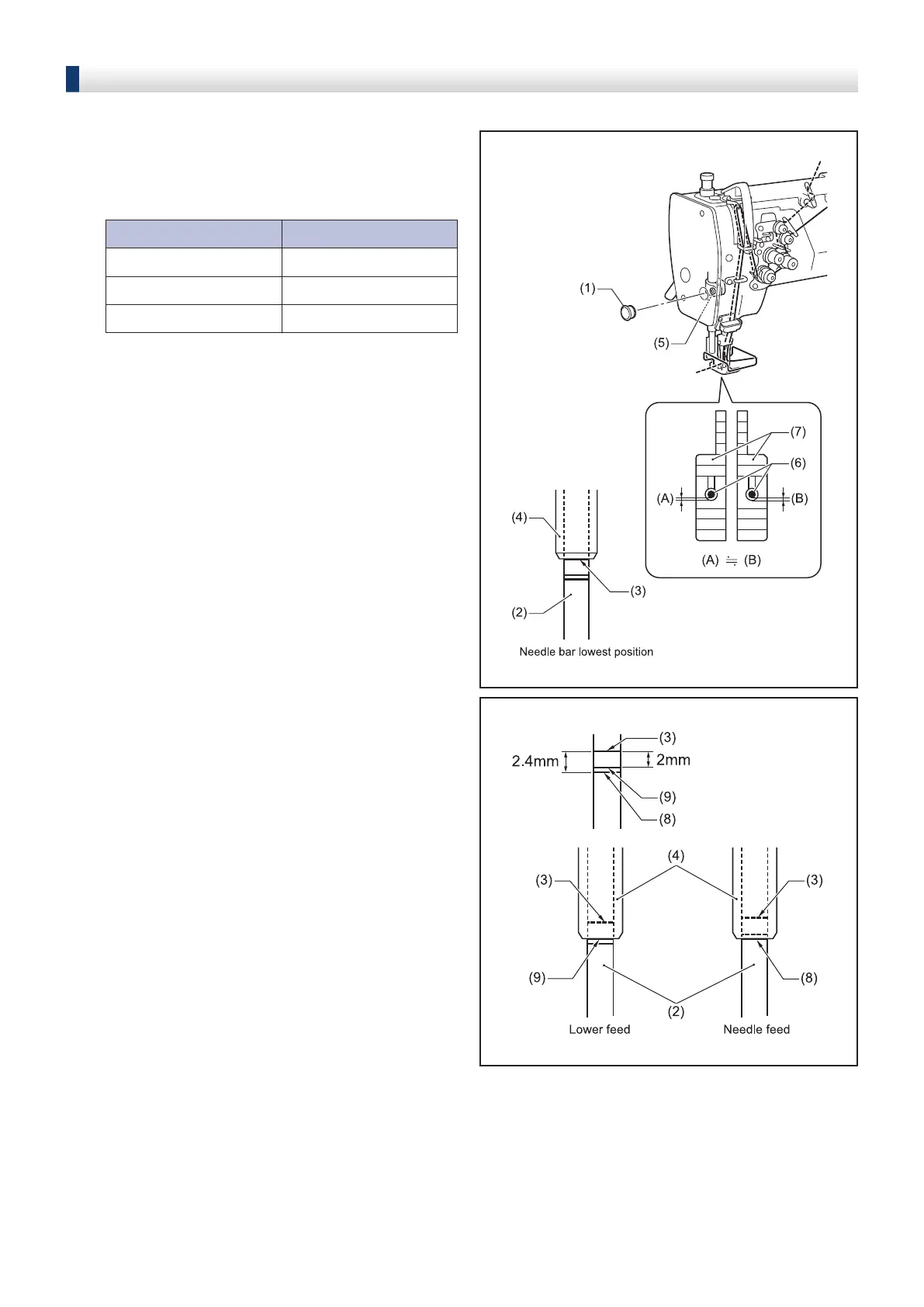

Turn the machine pulley forward to raise the

needle bar (2) until the reference line ((8) or (9),

depending on the feed condition) on the needle bar

(2) is aligned with the bottom edge of the needle

bar base (4).

7

In this condition, secure the machine pulley with

tape or similar, so that the needle bar (2) will not

move.

The procedure up to this point determines the

needle bar lift amount.

78

Loading...

Loading...