Model 771, 75, and 76-RH190 Transits 10

verticaltangentlock.

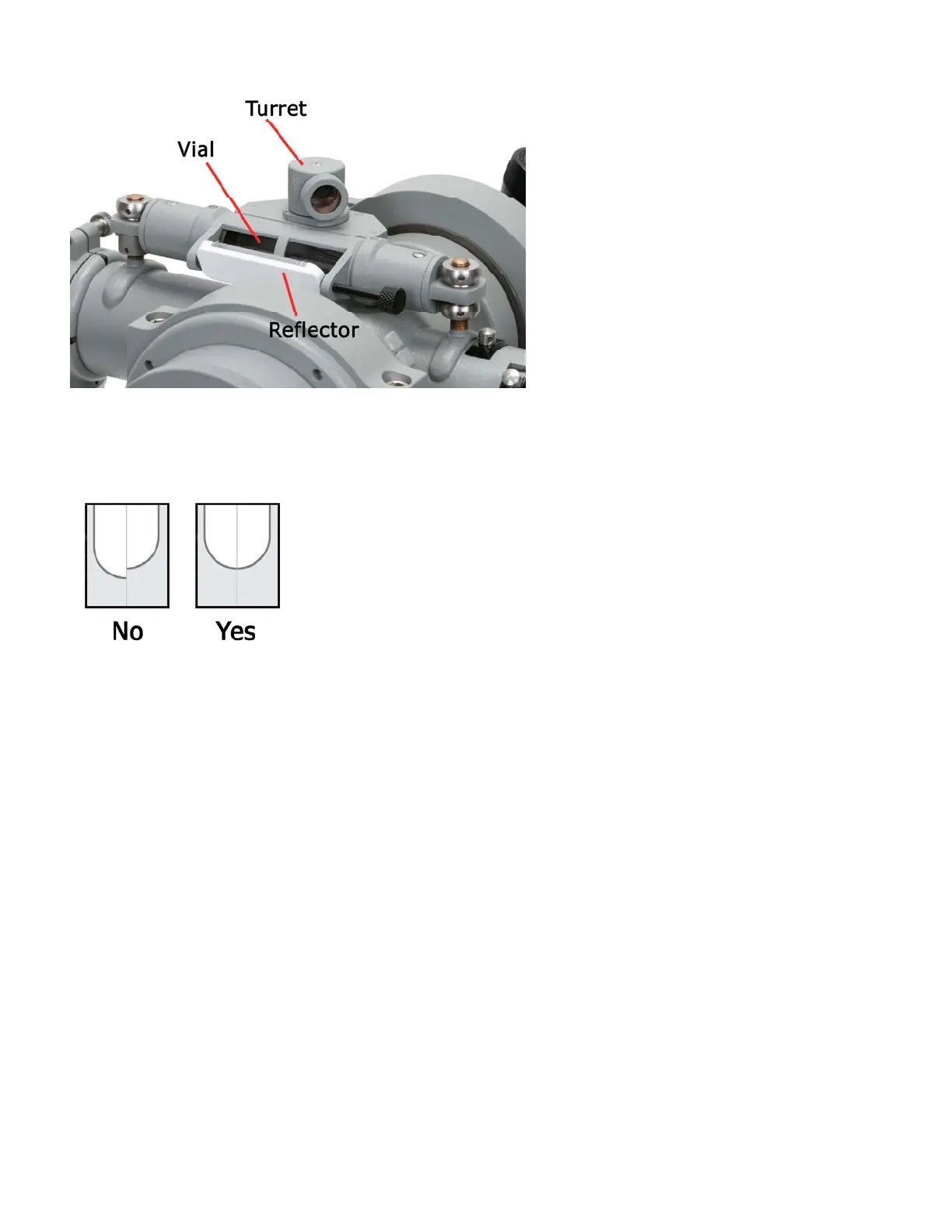

Thebubbleinthecoincidencevialop‐

erateslikeanyotherlevelvial,butthe

operatorviewsa“foldedimage”of

bothendsofthebubblesimultane‐

ously.Ifthetelescopeistilted,thetwo

bubbleimagesmoveinoppositedirec‐

tions.However,whenbothendsof

thebubblearebrought

“intocoinci‐

dence”(Figure2.5),thevialisdead

level.Youwillseesomethingsimilar

toFigure2.5bylookingintothevial’s

turret.Sincethehumaneyeisex‐

tremelyskillfulatdetectingeventiny

breaksinotherwisecontinuouslines,

thissystemmakesreadingthelevelextremelysensitiveandaccu‐

rate.

Rotatetheturretonthecoincidencevialsothatyoucanconven‐

ientlyviewthesplitimageofthebubbleinside.Areflectorhaving

onewhitesideandonemirroredsideisprovidedtohelpilluminate

theimage.Positionthereflectorforoptimalbubbleillumination.

1. Usingtheverticaltangentadjustmentscrew,bringthe

splitimageofthebubbleintocoincidence(Figure2.5).

2. Rotatethestandards180°sothatthetelescopeisnow

pointingintheoppositedirection.Ifthebubbleisoff

center,removeone‐halftheerrorwiththetwoleveling

screwswhicharelocateddirectlyunderthetelescope.

Removetheotherhalfoftheerrorusingtheverticaltan‐

gentscrew.Rememberthatyoucanseethebubbleby

lookingintothesideofthevialitselfratherthanintothe

turretwindow—thismayhelpyoudeterminewhichway

thebubblemustmove.

3. Nowrotate

thestandards90°sothatthetelescopeislo‐

cateddirectlyovertheotherpairoflevelingscrews.

Bringthebubbletocenter,usingonlythetwoleveling

screwsunderthetelescope.

4. Fromthisposition,rotatethestandards180°.Again,if

thebubbleisoffcenter,removeone‐halftheerrorwith

theverticaltangentscrew,andtheremainingone‐half

errorwiththetwolevelingscrewswhicharelocatedun‐

derthetelescope.

5. Repeatsteps2‐4,alternatingovereachpairofleveling

screws,untilthebubbleremainsincoincidenceinallfour

“compasspoint”positions.

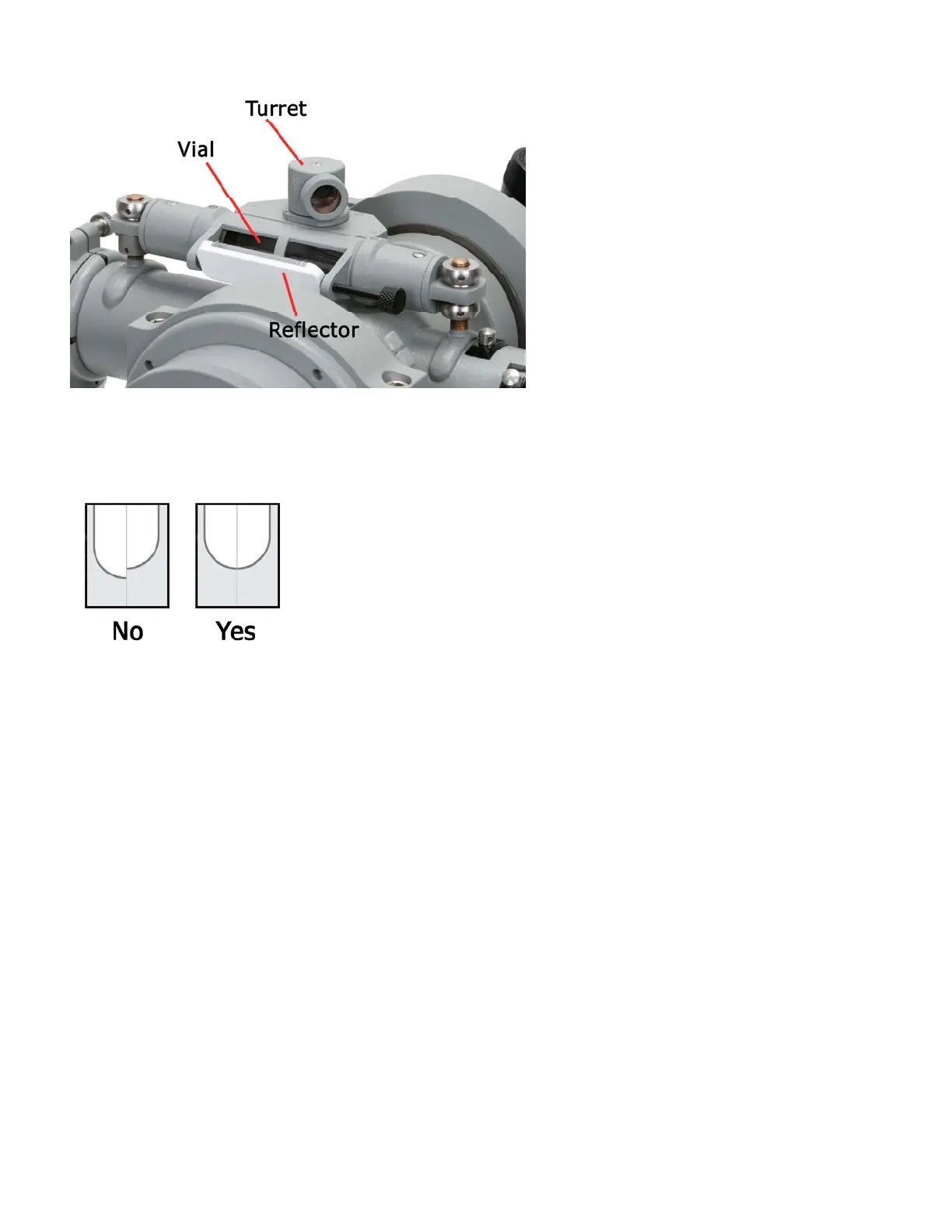

Figure2.4

Notethatthetransit’sverti‐

calspindlemaybebrought

intoplumb(exactlyvertical)

evenifthecoincidencevial

itselfisnotcalibratedprop‐

erlywithrespecttothetele‐

scopebarrel.

Figure2.5

Loading...

Loading...