37 Operation and Adjustment Manual

Mountthetransitfirmlyonanystandhavinga3½”‐

8externalthread.Loosenthehorizontaltangent

screwlock.

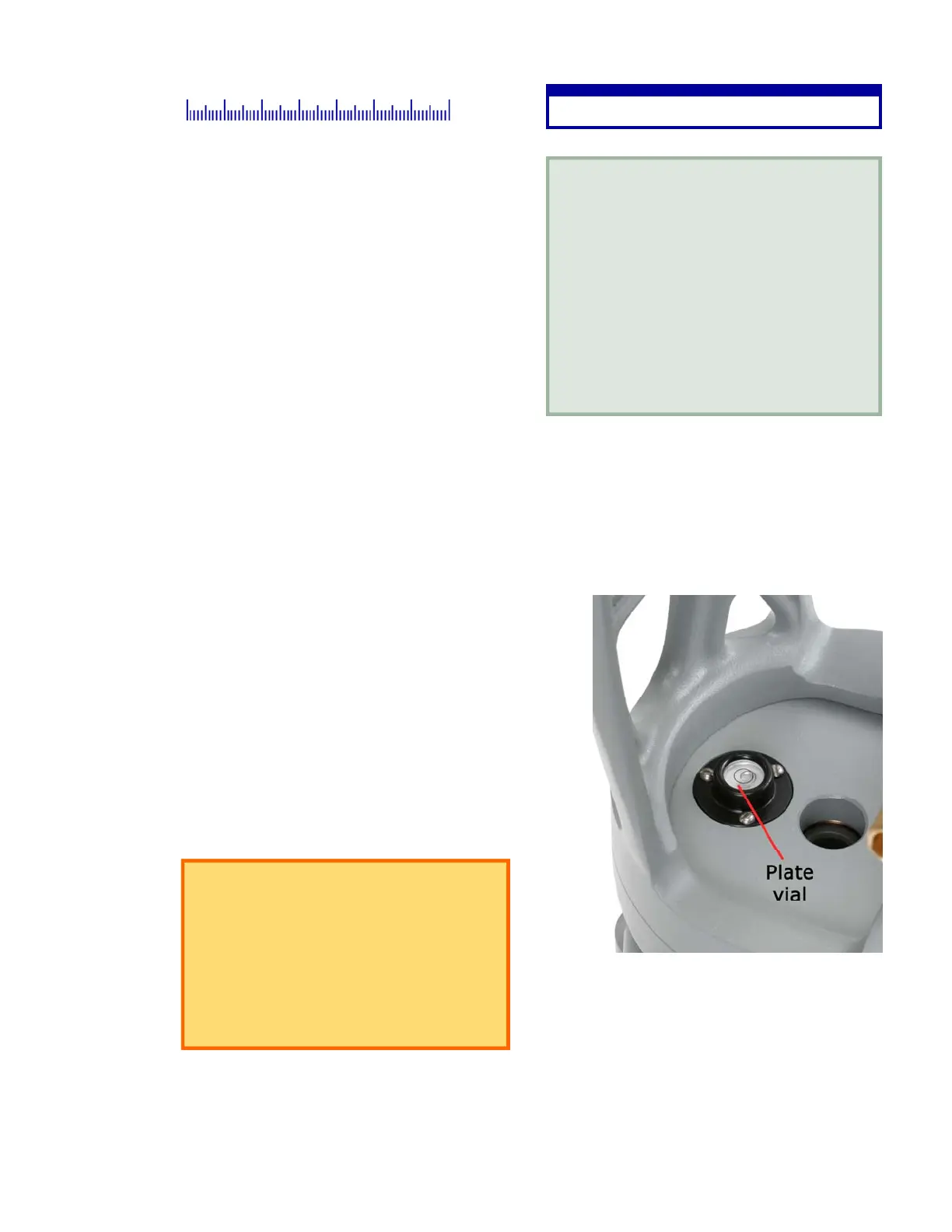

1.Viewtheplatevialfromaboveandbringitsbub‐

bletothecenterusingbothopposingpairsofinstru‐

mentlevelingscrews.Thisisidenticaltotherough

levelingprocessdescribedinChapter2.

2.Now,rotatethestandards180°sothatthetele‐

scopeispointingintheoppositedirection.Checkto

seewhetherthebubbleisstillinthecenterofthe

platevial.Ifso,theplatevialisinadjustment.Ifthe

bubbledoesnotremaincenteredwhentheinstru‐

mentisrotatedtothissecondposition,removeone

halfofthebubbleerrorusingthelevelingscrews(moveittoward

theinscribedcircle,butonlybyhalfway).

3.Securethehorizontaltangentclamplocktokeepthestandards

frommoving.Removetheotherhalfofthebubbleerrorusingthe

threesmallscrewslocatedaroundtheperimeterofthebaseofthe

platevial.Underthevialisathinspringwhichallowsthe

vialtotilt,sotighteninganygivenscrewwillmovethe

bubbleawayfromthatscrew,andlikewise,looseningany

givenscrewwillmovethebubbletowardthatscrew.

Whenyou’refinishedadjustingthebubblewiththesesmall

screws,itshouldbepreciselycenteredundertheinscribed

circle.

4.Loosenthehorizontaltangentlockandturnthetele‐

scope180°backtothefirstposition.Thebubbleshould

stillbecentered

undertheinscribedcircle.Ifnot,repeat

theprocessaboveuntilthebubbleremainsinsidethecircle

inbothpositions.

CAUTION:Donʹt“bottomout”the

platevialadjustmentscrews.Ifyoudo

this,thespringunderthevialwillbe

flattenedandproperadjustmentwillbe

impossible.Ifthishappens,loosenallof

thescrewsbythesameamount(aturn

ortwo),andcontinuetheadjustment

process.

Plate(“bull’seye”)Vial

Description:Establishwhetherthe

platevialindicatesalinewhichis

paralleltotheverticalspindle.

Tolerance:Bubblestayswithinthe

inscribedblackcircle.

Affectedparameters:None

Requiredequipment:Instrument

stand,smallscrewdriver

Figure4.1

Loading...

Loading...