47 Operation and Adjustment Manual

justmenttotiltthetrun‐

nionaxisintheappro‐

priatedirection.Todo

this,wemakeanup‐

wardordownwardad‐

justmentonthesideof

thetransitwhichhas

theobjectivelensofthe

cross‐axistelescope.

Therearetwowaysto

accomplishthedesired

adjustment.Wefirsttry

themethodrequiring

theleasteffort.Ifa

moreaggressiveadjust‐

mentisrequired,we’ll

moveontothesecond

method.

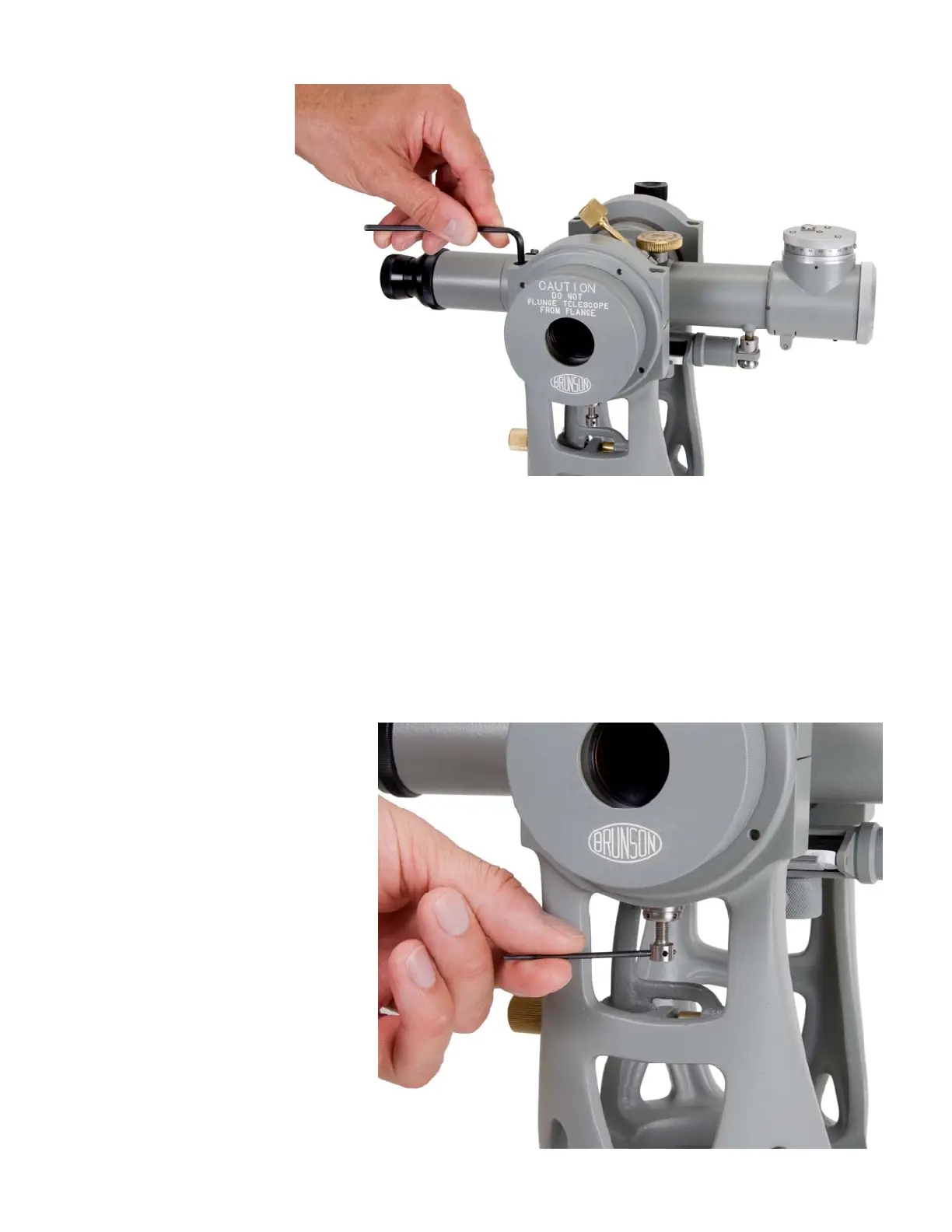

Thefirst,andeasiermethod,isasfollows.Tryslightlylooseningor

tighteningoneorbothofthesocketheadcapscrewsinthebearing

capabovetheobjectiveendofthecross‐axis(Figure4.10).Removeone

‐halfoftheapparenterrorinthismannerifpossible.Remember

thattheaxisboltsshouldnotbeoverlytightenednorshouldthey

beanythingresemblingloose.Theboltsshouldbefirmlyfinger/

handtight,notelbow/shouldertight.Whetheryouhavesuccessin

removingtheerrorbyusingonlytheseboltsdependsuponhow

tighttheboltsalreadyare,andhowfartheyneedtobemoved.

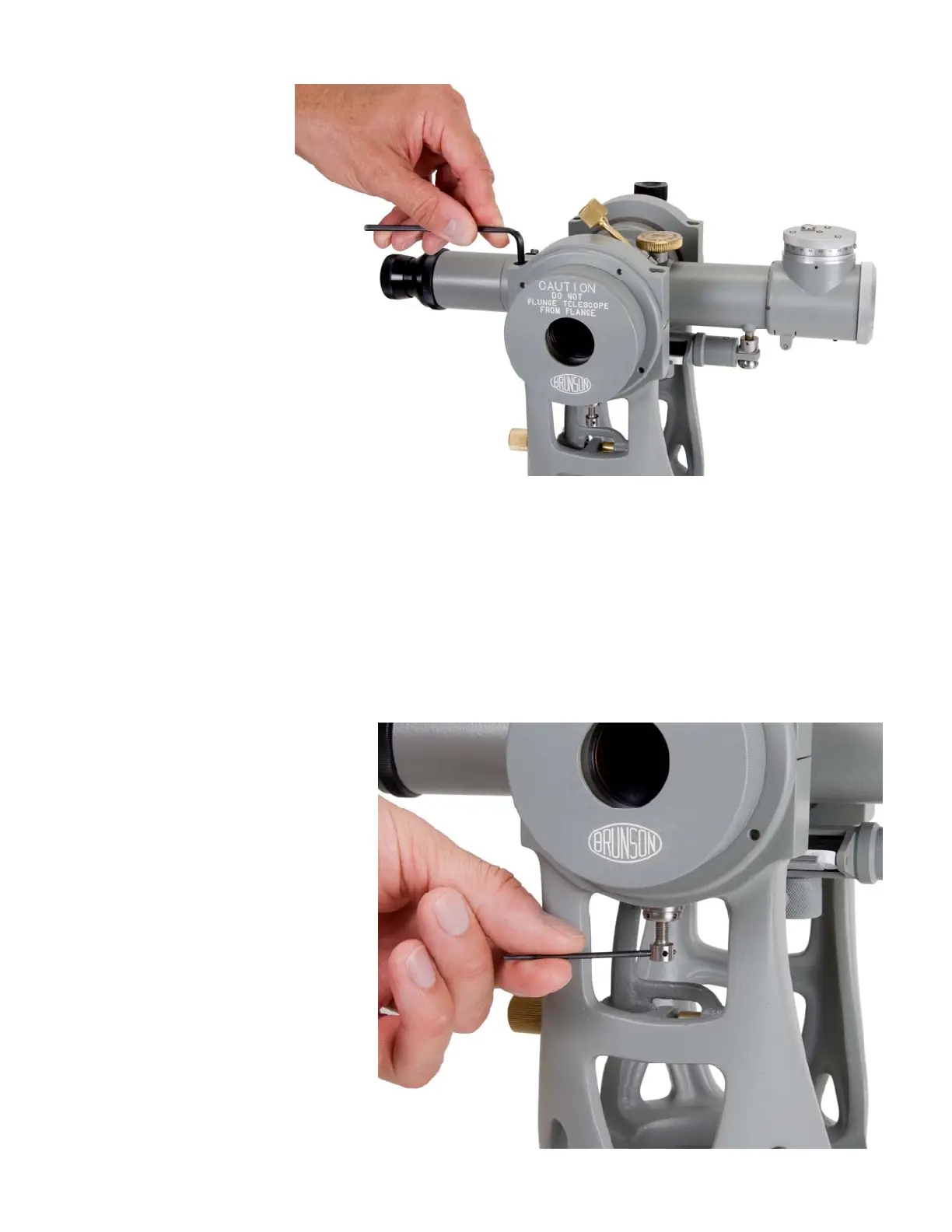

Ifthisprocedurecannotcompensatefortheerror,itwillbeneces‐

sarytoadjustthecapstan‐headed

boltlocatedunderthehorizontal

bearing(Figure4.11).

Boththecapstanboltandthe

bearingcappushonthehorizon‐

talbearingwhichiscapturedbe‐

tweenthem.Thecapstanbolthas

alocknutcinchedagainstthestan‐

dardsatthebottomofthebearing

housing.

Inordertoadjustthecapstanbolt,

slightlyloosen

thelocknut.Itis

alsonecessarytoslightlyloosen

thesocketheadcapscrewsinthe

bearingcapregardlessofwhether

youneedtomovethecapstanboltup

ordown.Thisisbecausethecom‐

pressiononthecapstanboltfrom

abovegenerallycreatestoomuch

frictionforthecapstan

boltto

Figure4.10

Figure4.11

Loading...

Loading...