Model 771, 75, and 76-RH190 Transits 50

lightinginthereferenceinstrument’smaintelescope(orswitchthe

lightsourcefromoneinstrumenttotheother).

5.Lookthroughthetesttransit’scross‐axistelescopeeyepieceand

youshouldseethereferenceinstrument’sbacklitreticle.Whenyou

rotatethetesttransit’smaintelescope,youwillseeitscross‐axis

re‐

ticlerotateaswell.Bydoingthis,putthecross‐axisreticledirectly

intoregisterwiththereferenceinstrument’sreticle.Youcannow

makeanynecessaryadjustmentstothetesttransittobringthereti‐

cleimagespreciselyintoregister.Usethehorizontaltangentad‐

justmentscrewforhorizontal

adjustments,andusethetwoleveling

screwswhichareinlinewiththereferenceinstrumenttomakever‐

ticaladjustments.

6.Oncethetesttransit’scross‐axisispreciselyregistered

withthereferenceinstrument,rotatethemaintelescope180°.

Anyerrorinthecross‐axistelescopewillshowupasadevia‐

tionbetweenthetworeticles.Ifthereisanyerror,itmaybe

intheverticaldirection,horizontaldirection,orboth.Itis

necessarytoestimatethiserror,sinceingeneralwedonot

haveanangle‐measuringopticalwedgeinthefield.There‐

forewerelyonreticlegeometry.

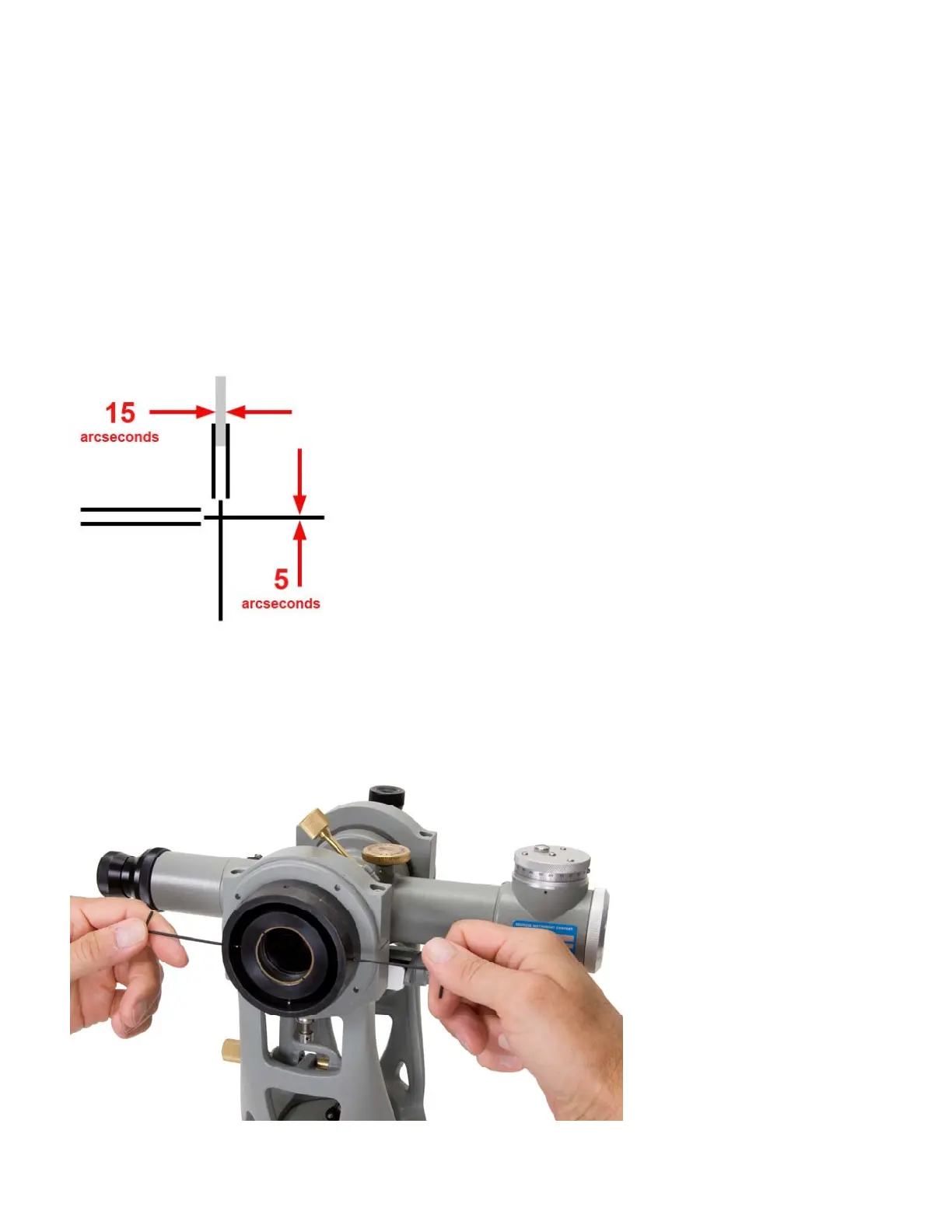

Weknowthatthewidthofareticlewireis5arcseconds,and

thegapbetweenthereticlepairis15arcsecondswide(Figure

4.7).Therefore,wecanmakeanestimateoftheobserveder‐

ror,rememberingthattheobservederroristwicetheactual

error.Thisfactmakestheerroreasiertosee.

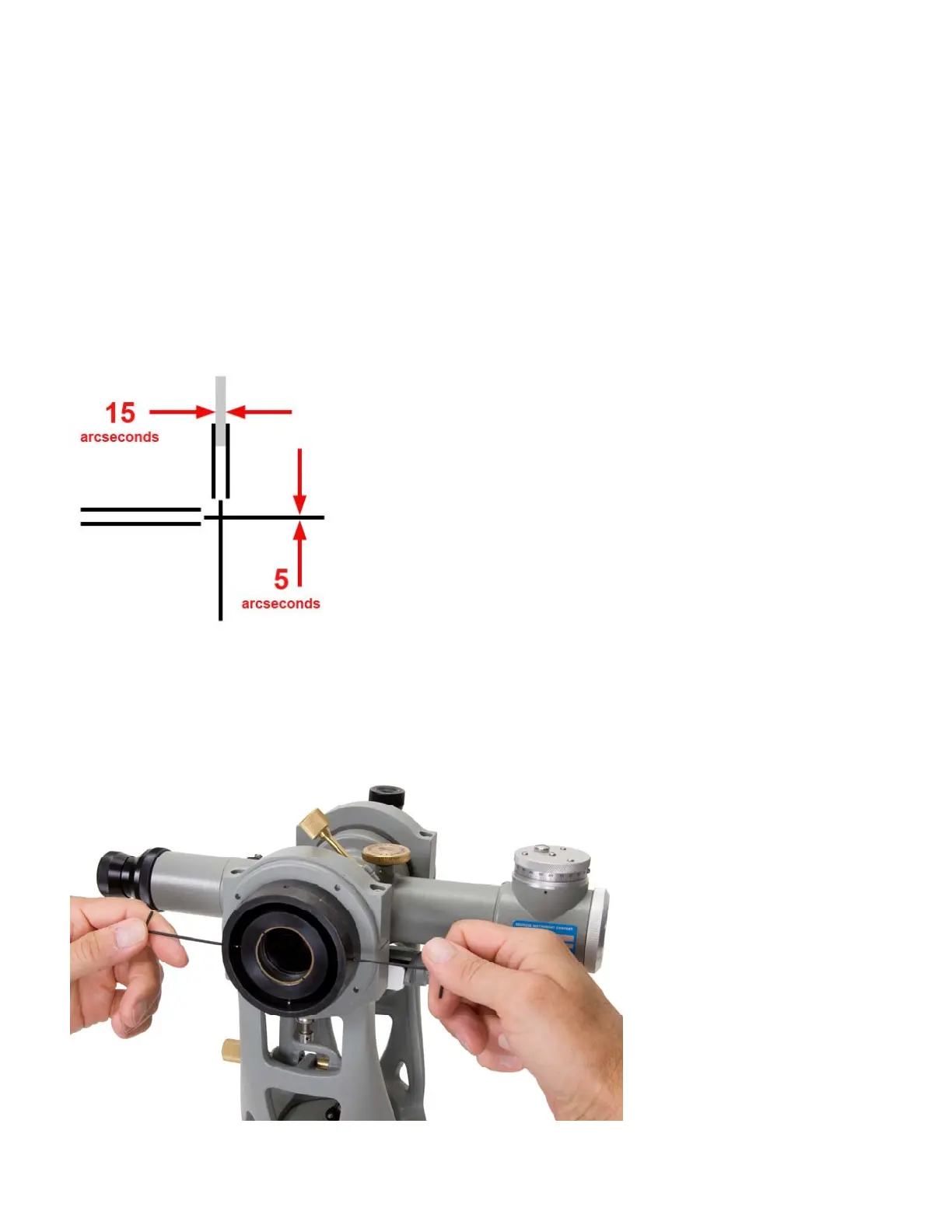

7.Iftheobservederrorexceeds2arcseconds,adjustmentisre‐

quired.Removetheflangecoverfromtheobjectiveendofthecross

‐axistelescopesimplybypullingitstraightoff(it’safrictionfit).

Thenmovethesocketheadset‐screwsinthecross‐axistelescope

objectivelensmounting

flangetophysicallypush

thelensfromsidetosideto

correctthiserror.Asyou’d

expect,usethehorizontally

opposedadjustmentscrews

toshifttheimagehorizon‐

tally,andtheverticallyori‐

entedscrewstoshifttheim‐

agevertically(Figure4.8).

Rememberthat

youshould

removeonlyhalfoftheap‐

parenterror.

8.Repeatsteps5through7

untiltheerrorobservedis

withintheallowabletoler‐

ance.

Figure4.8

Figure4.7

Loading...

Loading...