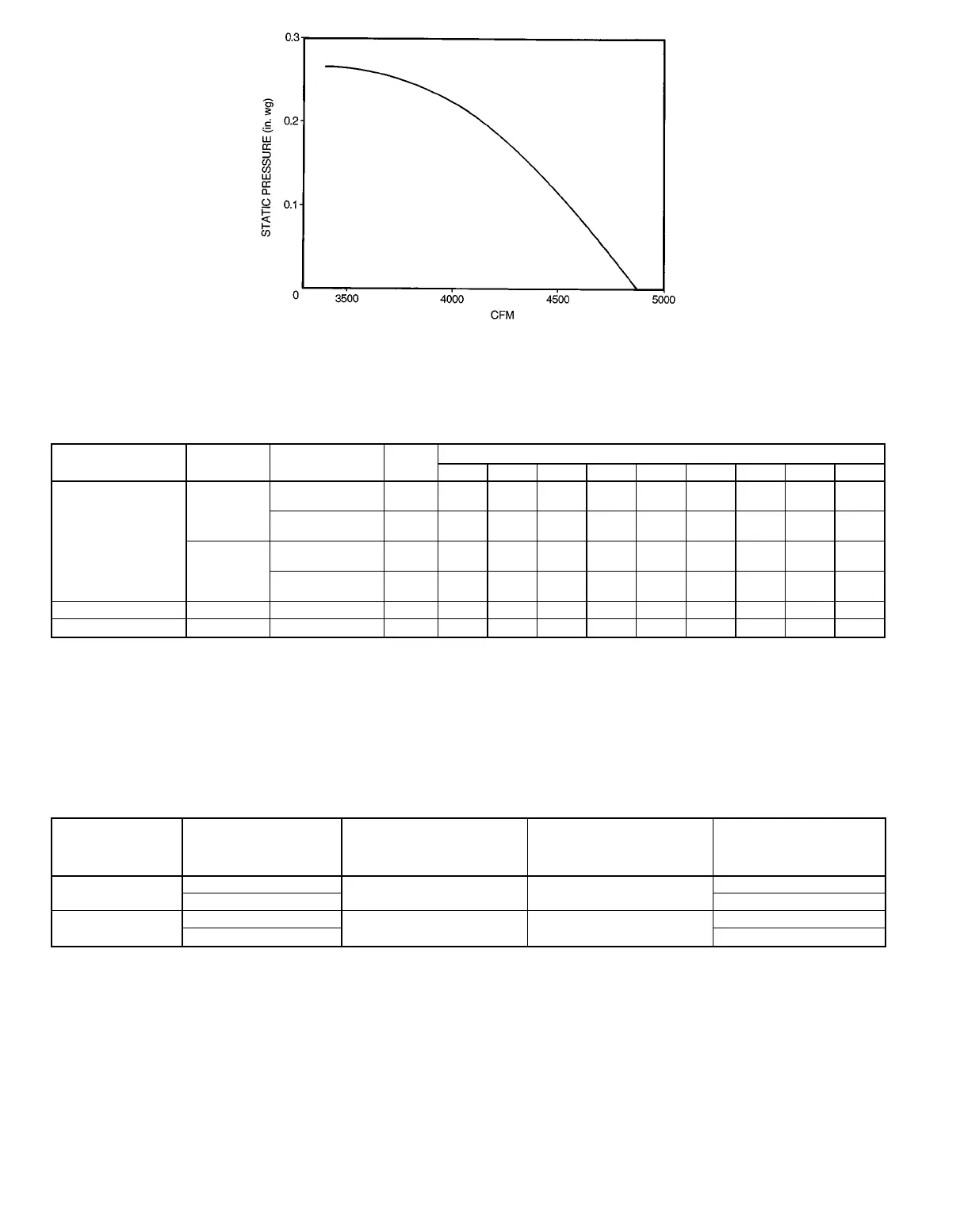

Table 7 — Accessory/FIOP Static Pressure (in. wg)

ACCESSORY/FIOP UNIT SIZE UNIT VOLTAGE kW

CFM

3750 4000 4500 5000 5600 6000 6250 7200 7500

Electric Heaters

150

208/230-3-60

14-34

42,56

0.05

0.06

0.05

0.06

0.06

0.07

0.07

0.08

0.08

0.10

0.09

0.12

0.09

0.13

††

460-3-60

15,32

55

0.05

0.06

0.05

0.06

0.06

0.07

0.07

0.08

0.08

0.10

0.09

0.12

0.09

0.13

††

180

208/230-3-60

26,34

42,56

****

0.10

0.08

0.09

0.12

0.09

0.13

0.11

0.16

0.12

0.17

460-3-60

32

55

****

0.10

0.13

0.09

0.12

0.09

0.13

0.11

0.15

0.12

0.17

Economizer All All — 0.03 0.03 0.04 0.05 0.06 0.07 0.07 0.09 0.10

Glycol Coil All All — 0.16 0.18 0.22 0.26 0.31 0.35 0.37 0.44 0.46

LEGEND

FIOP — Factory-Installed Option

*Do not operate unit with electric heat at this cfm. Operation at this cfm

is below electric heat required minimum cfm.

†Do not operate unit at this cfm. Operation at this cfm is above unit

maximum cfm limit.

NOTES:

1. Heaters are rated at 208/240 v and 480 v.

2. The factory assembled horizontal adapter substantially improves fan

performance. See Fig. 23.

3. The static pressure must be added to external static pressure. The

sum and the indoor-air section entering-air cfm should then be used

in conjunction with the Tables 5 and 6 to determine blower rpm, bhp,

and watts.

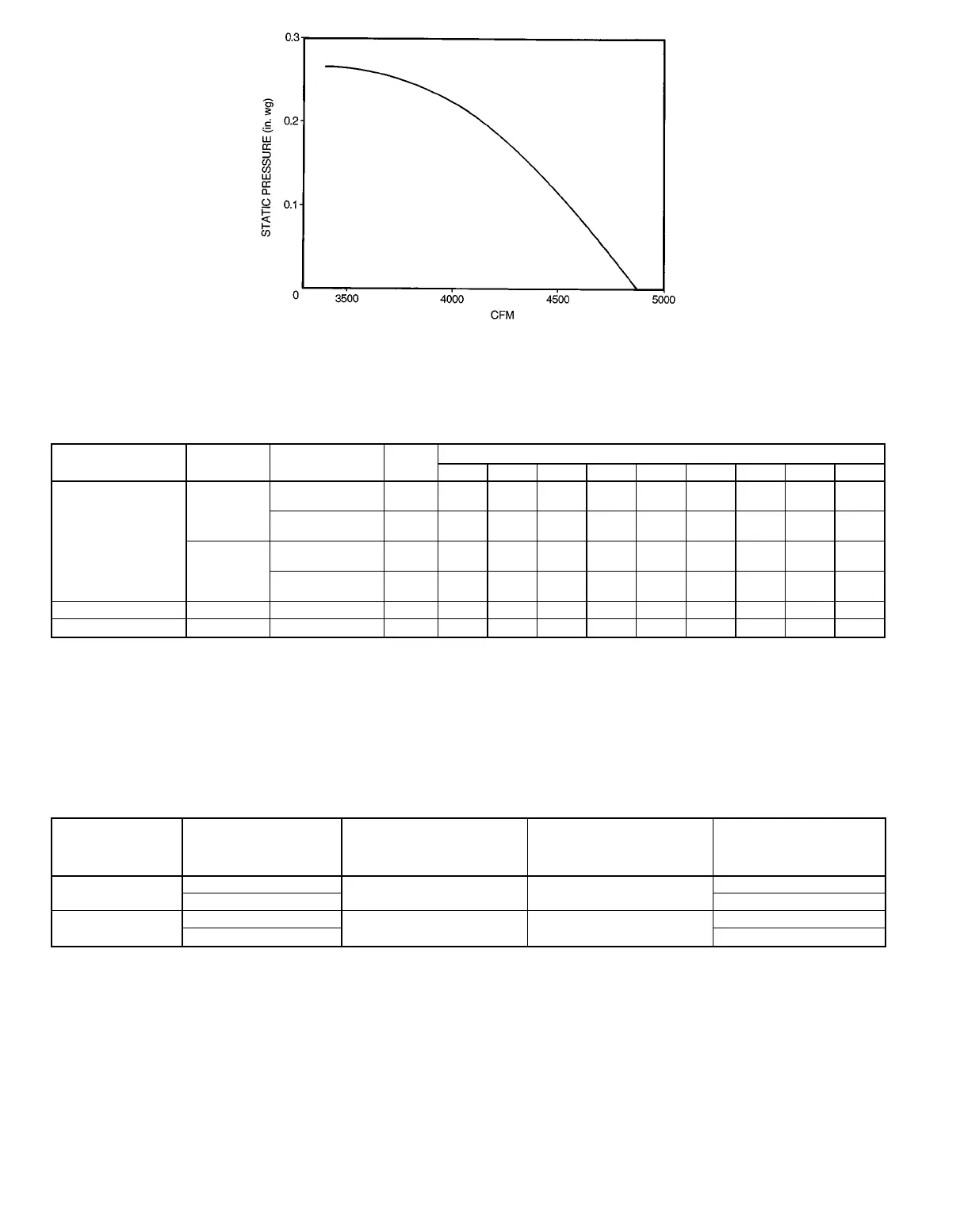

Table 8 — Indoor-Fan Motor Performance

UNIT

542J

UNIT

VOLTAGE

MAXIMUM

ACCEPTABLE

CONTINUOUS

BHP*

MAXIMUM

ACCEPTABLE

OPERATING

WATTS

MAXIMUM

AMP DRAW

150

208/230

4.25 3775

10.5

460 4.8

180

208/230

5.90 5180

15.8

460 7.9

LEGEND

Bhp — Brake Horsepower

*Extensive motor and electrical testing on these units ensures that the

full horsepower range of the motors can be utilized with confidence.

Using your fan motors up to the horsepower ratings shown in this table

will not result in nuisance tripping or premature motor failure. Unit war-

ranty will not be affected.

Fig. 24 — Fan Performance Using Accessory Power Exhaust

—18—

Loading...

Loading...