22

LEGEND NOTES:

1. Direct interpolation is permissible. Do not extrapolate.

2. The following formulas may be used:

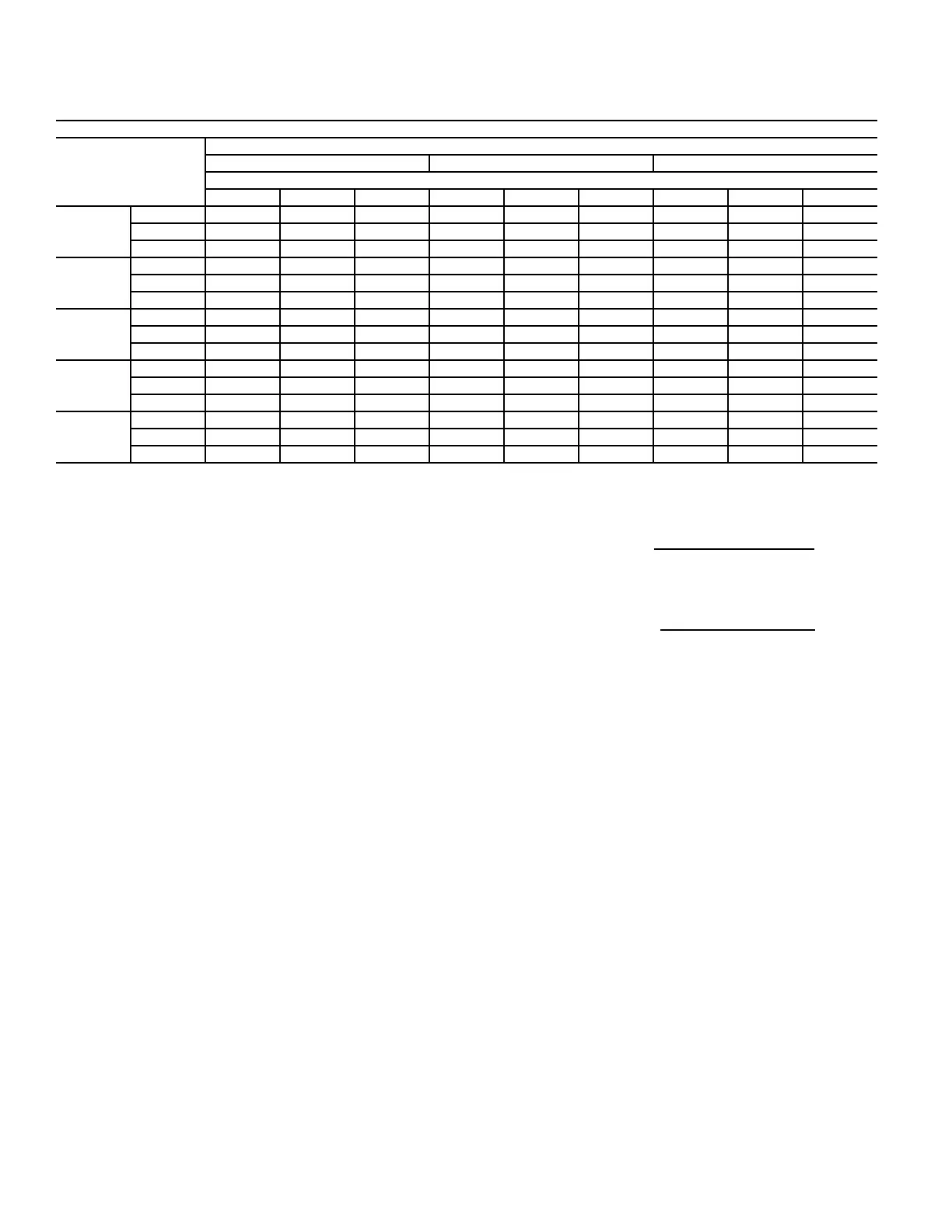

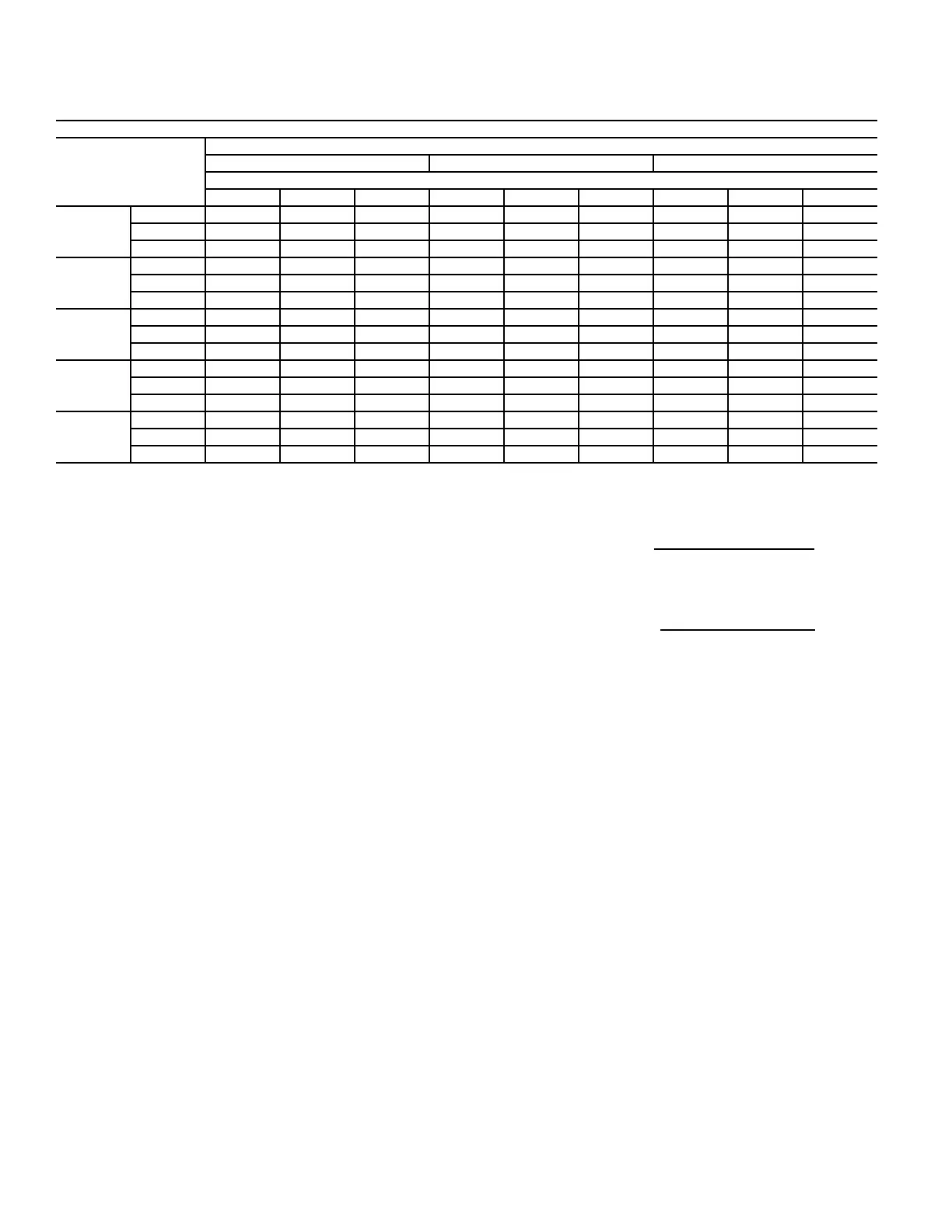

COOLING CAPACITIES (1-STAGE COOLING) 3 TONS (cont)

582J*04G (3 TONS) - UNIT WITH PERFECT HUMIDITY SYSTEM IN SUBCOOLING MODE

TEMP (F) AIR ENT

CONDENSER (Edb)

AIR ENTERING EVAPORATOR - SCFM

900 1200 1500

Air Entering Evaporator - Ewb (F)

72 67 62 72 67 62 72 67 62

75

TC 30.9 32.0 31.9 30.7 33.5 34.3 34.8 31.8 27.6

SHC 15.1 20.0 26.3 25.1 20.4 15.4 14.0 18.2 21.9

kW 2.51 2.49 2.42 2.82 2.74 2.68 3.09 3.01 2.88

85

TC 32.8 28.4 23.4 18.7 23.8 29.3 24.5 18.8 13.6

SHC 11.0 14.6 17.9 13.4 10.3 7.1 2.6 5.6 8.6

kW 3.36 3.23 3.06 3.62 3.41 3.24 3.79 3.58 3.39

95

TC 31.3 32.0 31.9 30.7 33.5 34.3 34.8 31.8 27.6

SHC 15.3 20.0 26.3 25.1 20.4 15.4 14.0 18.2 21.9

kW 2.53 2.49 2.41 2.82 2.74 2.68 3.09 3.01 2.88

105

TC 32.8 28.4 23.4 18.7 23.8 29.3 24.5 18.8 13.6

SHC 11.0 14.6 17.9 13.4 10.3 7.1 2.6 5.6 8.6

kW 3.36 3.23 3.06 3.62 3.41 3.24 3.79 3.58 3.39

115

TC 31.3 32.0 31.9 30.7 33.5 34.3 34.8 31.8 27.6

SHC 15.3 20.0 26.3 25.1 20.4 15.4 14.0 18.2 21.9

kW 2.53 2.49 2.41 2.82 2.74 2.68 3.09 3.01 2.88

Edb — Entering dry-bulb

Ewb — Entering wet-bulb

kW — Compressor motor power input

Ldb — Leaving dry-bulb

Lwb — Leaving wet-bulb

SHC — Sensible capacity (1000 Btuh) gross

TC — Total capacity (1000 Btuh) gross

t

ldb

= Wet-bulb temperature corresponding to enthalpy of air leaving evapora-

tor coil (h

lwb

)

Where h

ewb

= Enthalpy of air entering evaporator coil

t

ldb

=t

edb

– sensible capacity (Btuh)

1.10 x cfm

h

lwb

=h

ewb

– total capacity (Btuh)

4.5 x cfm

PERFORMANCE DATA (CONT)

Loading...

Loading...