4.6 Spray chilling accessory

During spray chilling a hot melt is dispersed into a cold gas stream. The droplets are solidified into

particles and are separated. The matrix substance and the active ingredients are heated above the

melting point. Highest melting point is 70 °C. The nozzle is also heated to prevent any blocking. No

additional thermostat is required, as the existing heating control and peristaltic pump in the instrument

are used. If the sample has a low melting point, then the inlet air is cooled to increase the temperature

gradient. If lower temperatures than 10 °C (provided by the B-296) are used, e.g. for hard fats, the

inlet air can be cooled to –5 °C by using a specially developed refrigeration unit (please contact your

local distributor.

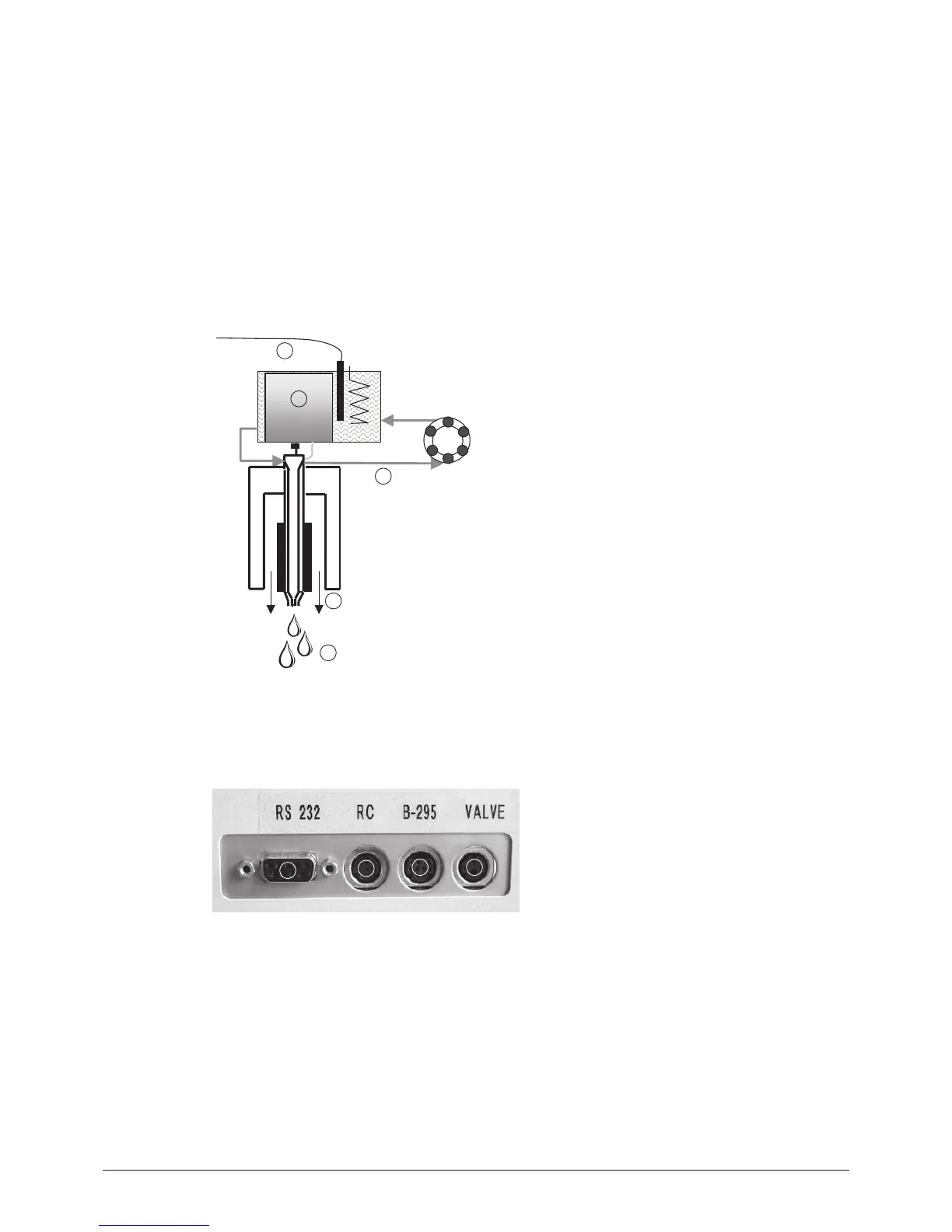

1

2

3

4

5

a Temperature sensor

b Circulating heating liquid to bath – nozzle –

peristaltic pump – bath

c Cold gas

d Heated feed sample

e Droplets spray

Fig. 4.5: Functional principle of the sample feed and dispersion

4.7 Connected accessories to the Mini Spray Dryer B-290

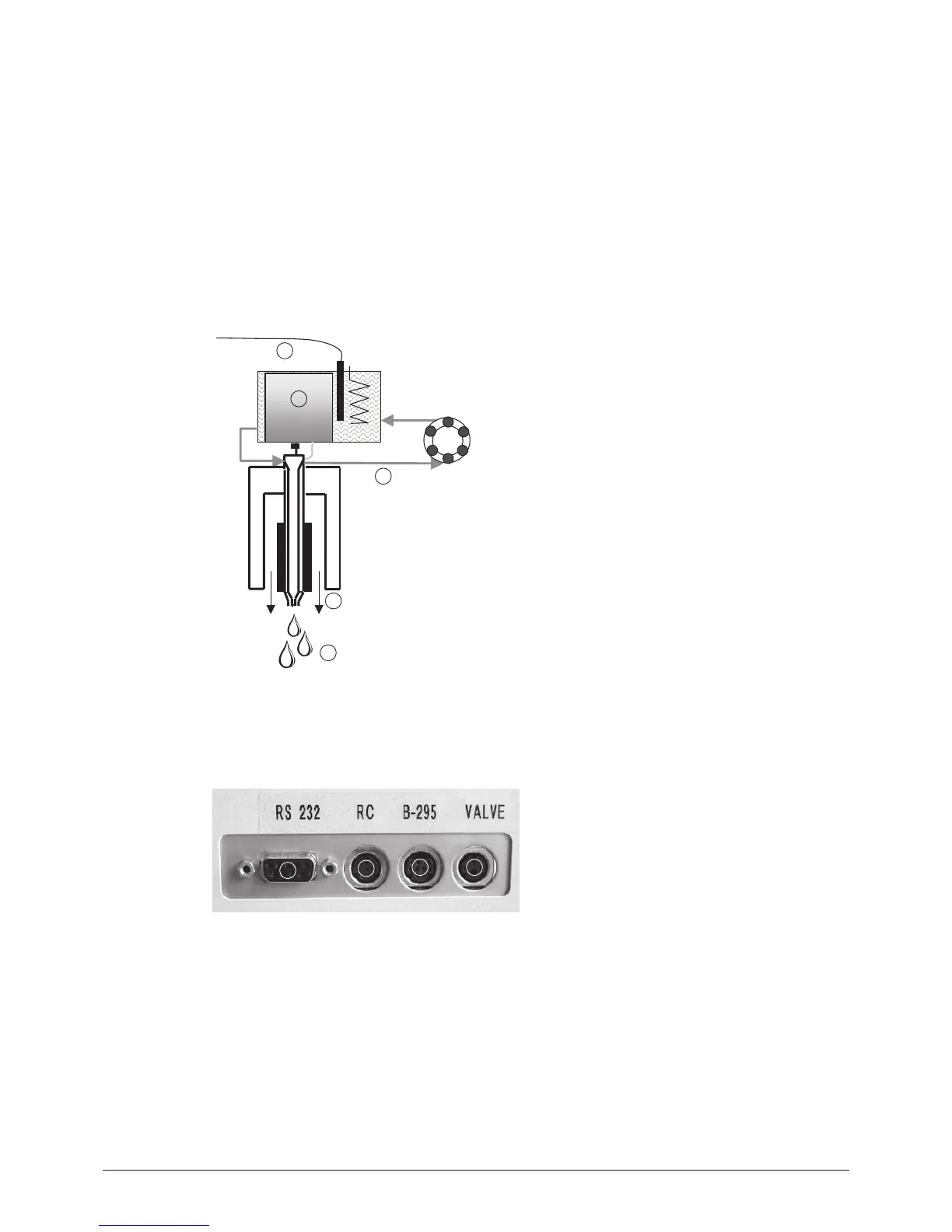

1

2

3 4

a Serial port RS-232 for data output to a PC

b Connection for the remote control panel

c Connection for Inert Loop B-295

d Connection for feed switch valve

Fig. 4.6: Rear connections of the Mini Spray Dryer B-290

Loading...

Loading...