46

f. Locate and remove 1½” NPT x 2” long black

nipple, 1½” x 1½” x ¾” NPT black tee, ¾” x ¼”

NPT black reducing bushing and Temperature &

Pressure Gauge.

g. Mount the nipple into 1½” FPT boiler supply

tapping (see Figures 1A and 1B), then, install the

tee onto the nipple, making sure ¾” branch outlet

is in horizontal plane and facing the boiler front.

h. Install ¾” x ¼” NPT black reducing bushing

into the tee branch, then, put in Temperature &

Pressure Gauge.

2. APX800 Boiler Model

a. Locate and remove (1) ¾” NPT x close black

nipple, (1) ¾” NPT x 12” black nipple, ¾” NPT

black tee, ¾” FPT x 1” FPT Pressure Relief

Valve, ¾” NPT Drain Valve.

b. Install close nipple into tee branch, then, screw

the assembly into boiler left side front ¾”

tapping making sure tee run outlets are in vertical

plane and parallel to boiler side.

c. Install the ¾” NPT x 12” black nipple into tee

run top outlet.

d. Mount ¾” FPT x 1” FPT Pressure Relief Valve

onto 12” nipple.

e. Install Drain Valve into the tee bottom outlet.

f. Locate and remove 2” NPT steel coupling, 2”

NPT x 2-1/2” long black nipple, 2” x 2” x ¾”

NPT black tee, ¾” x ¼” NPT black reducing

bushing and Temperature & Pressure Gauge.

g. Mount 2” NPT coupling onto 2” MPT boiler

supply stub (see Figure 1C), then, install 2”

NPT x 2-1/2” long black nipple into the coupling

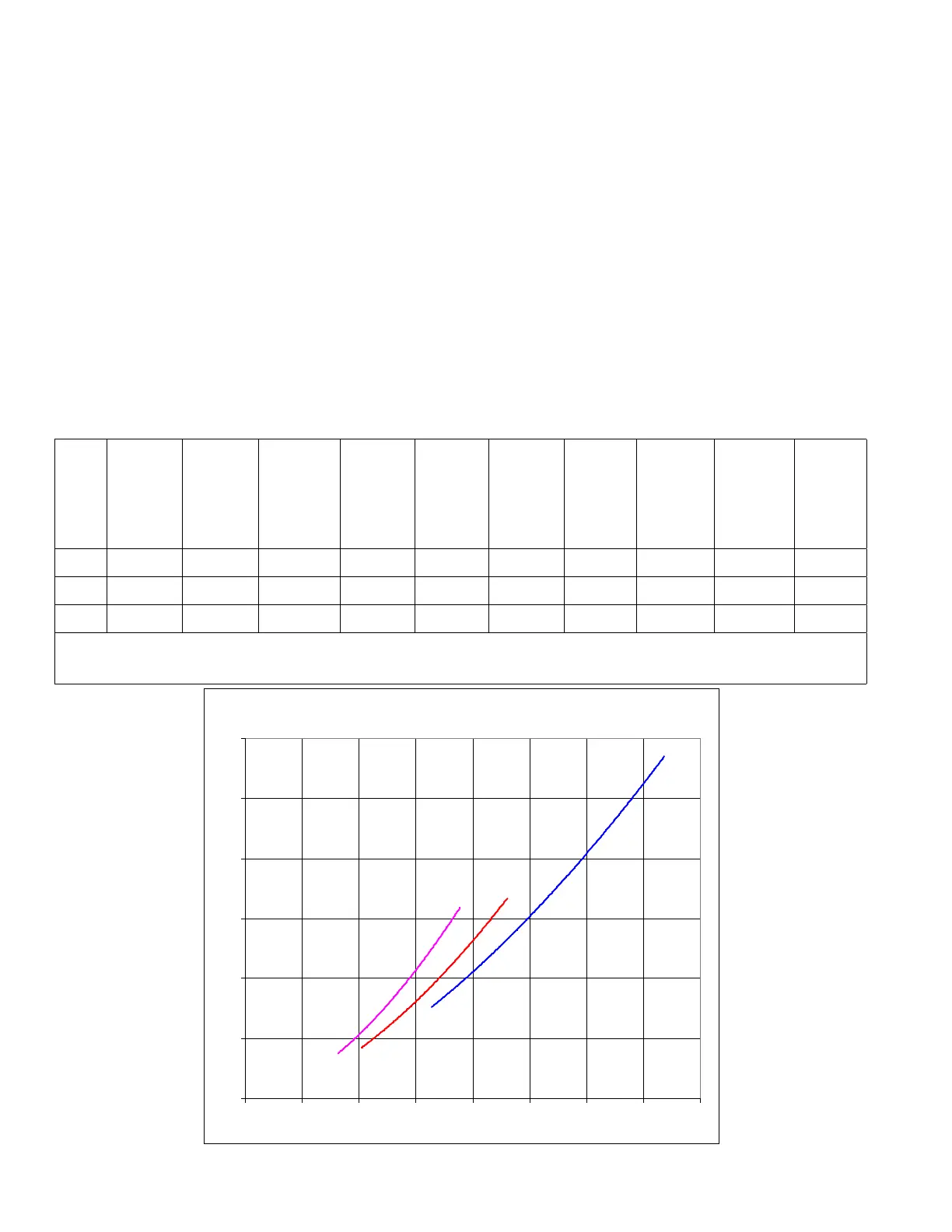

VI. Water Piping and Trim A. Factory Supplied Piping and Trim (continued)

Boiler

Model

Boiler

Supply

Connection,

Inch, FPT

Boiler

Return

Connection,

Inch, FPT

Minimum

Required

Flow (GPM)

@ 35°F DT

Boiler

Head Loss,

Ft.

@ 35°F DT

Required

Flow,

(GPM)

@ 30°F DT

Boiler

Head Loss,

Ft.

@ 30°F DT

Required

Flow,

(GPM)

@ 25°F DT

Boiler Head

Loss, Ft. @

25°F DT

Maximum

Required

Flow (GPM)

@ 20°F DT

Boiler

Head

Loss, Ft.

@ 20°F DT

APX399 1½ 1½ 21.5 6.1 25.1 7.9 30.2 10.8 37.7 15.9

APX500 1½ 1½ 27.1 6.9 31.7 8.9 38.0 12.1 47.5 17.6

APX800 2 2 43.4 12.1 50.7 15.5 60.8 20.9 76.0 30.0

Notes: Required Flow (GPM) = ** Output (MBH) * 1000/500 * DT

** Output (MBH) - Select Value for specic Boiler Model from Table 2A or 2B

Using boiler antifreeze will result in higher uid density and may require larger circulators.

Table 14: Flow Range Requirement Through Boiler

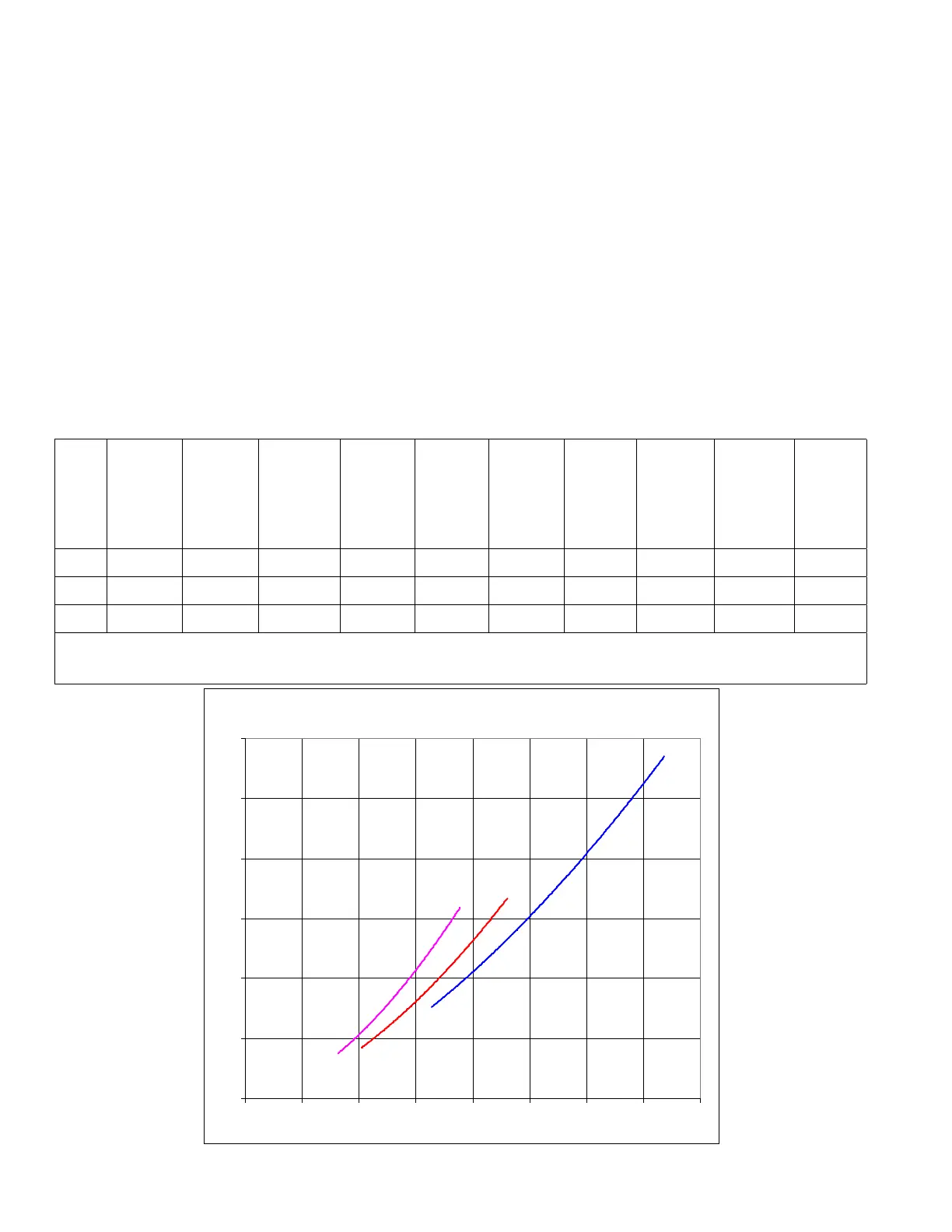

399

500

800

0

5

10

15

20

25

30

0 10 20 30 40 50 60 70 80

Flow Rate (GPM)

Pressure Drop (Feet of Head)

Loading...

Loading...