Troubleshooting | 12

Instruction Manual COBRA NC 2500 B WCV_EN_en 43 | 52

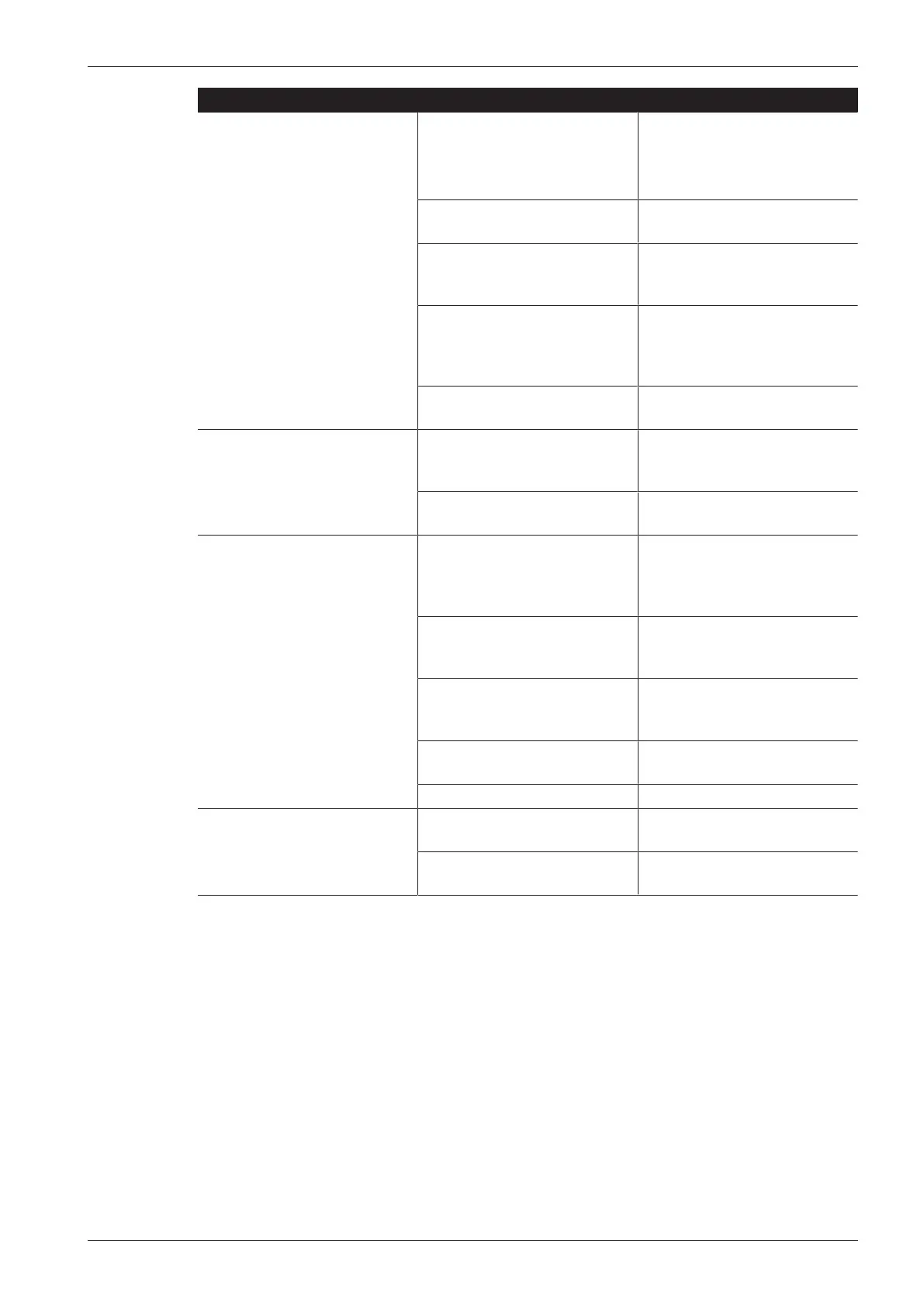

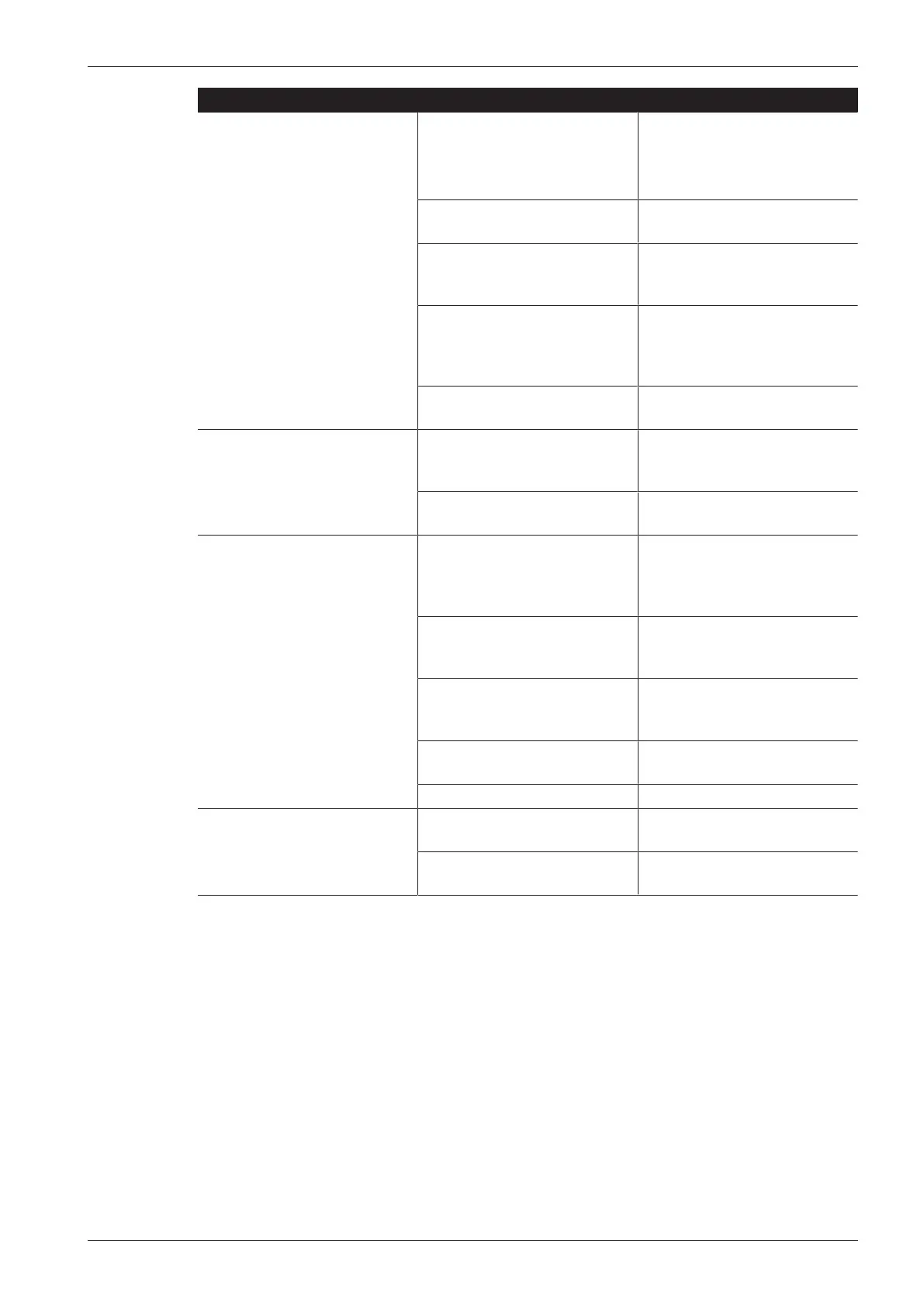

Problem Possible Cause Remedy

The machine does not reach

the usual pressure on the suc-

tion connection.

Suction or discharge lines too

long or section diameter too

small.

● Use larger diameter or

shorter lines.

● Seek advice from your local

Busch representative.

Process deposits on the pump-

ing components

● Flush the machine.

If an inlet screen or an inlet fil-

ter is installed, it can be partial-

ly clogged.

● Clean the inlet screen or re-

place the inlet filter car-

tridge.

The machine runs in the wrong

direction.

● Check the direction of rota-

tion, see Wiring Diagram

Three-Phase Motor (Pump

Drive) [➔21].

Internal parts are worn or

damaged.

● Repair the machine (contact

Busch).

The machine runs very noisily. Wrong oil quantity or unsuit-

able oil type.

● Use one of the recommend-

ed oils in the correct quanti-

ty, see Oil [➔46].

Defective gears, bearings or

coupling element.

● Repair machine (contact

Busch).

The machine runs too hot. Insufficient cooling. ● Make sure to comply with

the cooling water require-

ments, see Cooling Water

Connection [➔14].

Ambient temperature too high. ● Observe the permitted am-

bient temperature, see

Technical Data.

Temperature of the process

gases at the inlet too high.

● Observe the permitted gas

inlet temperature, see Tech-

nical Data.

The cooling water pump is de-

fective.

● Repair the machine.

Oil level too low. ● Top up oil.

The oil is black. Oil change intervals are too

long.

● Drain the oil and fill in new

oil, see Oil Change [➔31].

The machine runs too hot. ● See problem "The machine

runs too hot".

For resolution of problems not listed in the troubleshooting table, please contact your Busch repre-

sentative.

Loading...

Loading...