12 | Troubleshooting

24 | 32 Instruction Manual R5 KB KC 0010-0016 E_EN_en

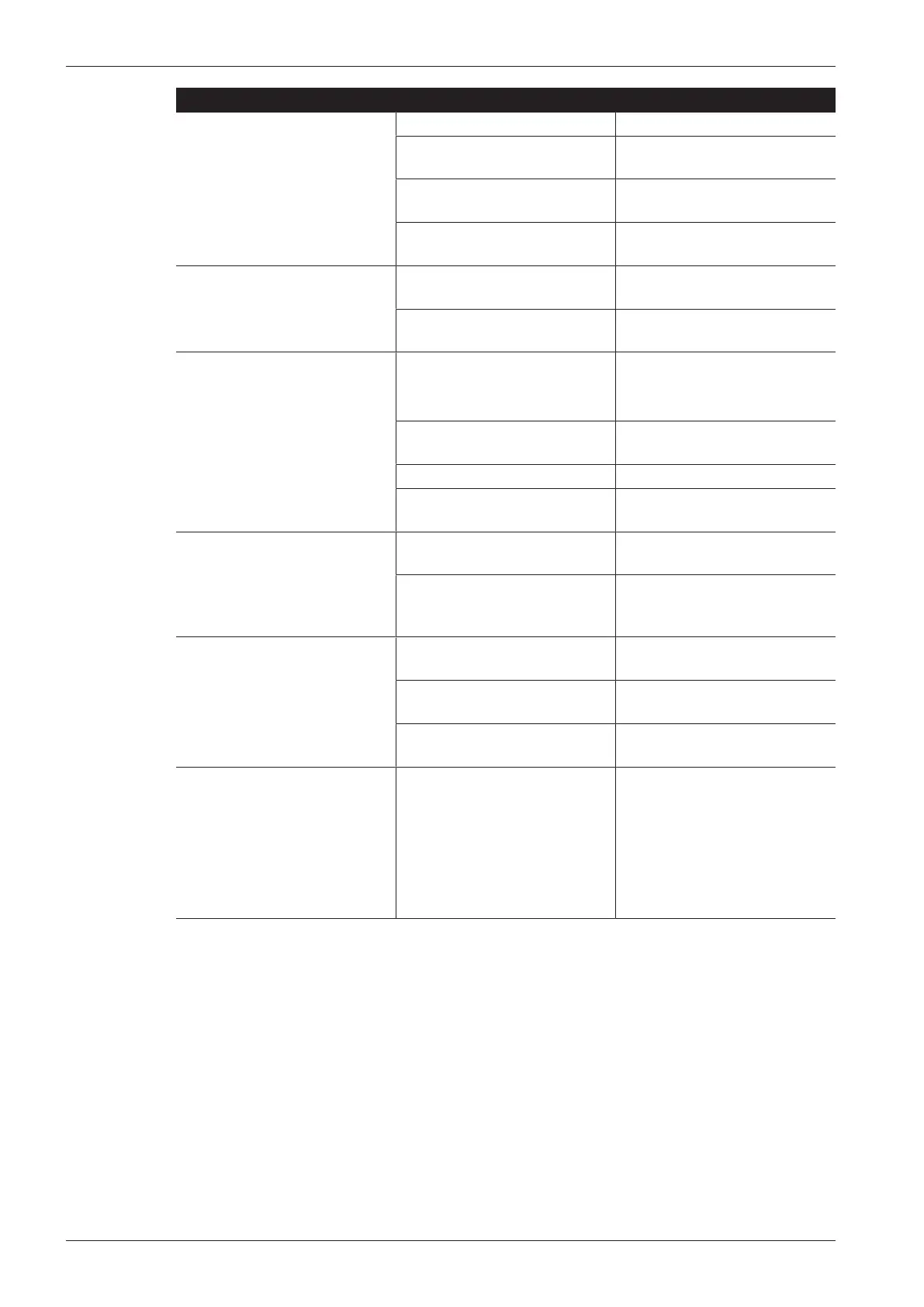

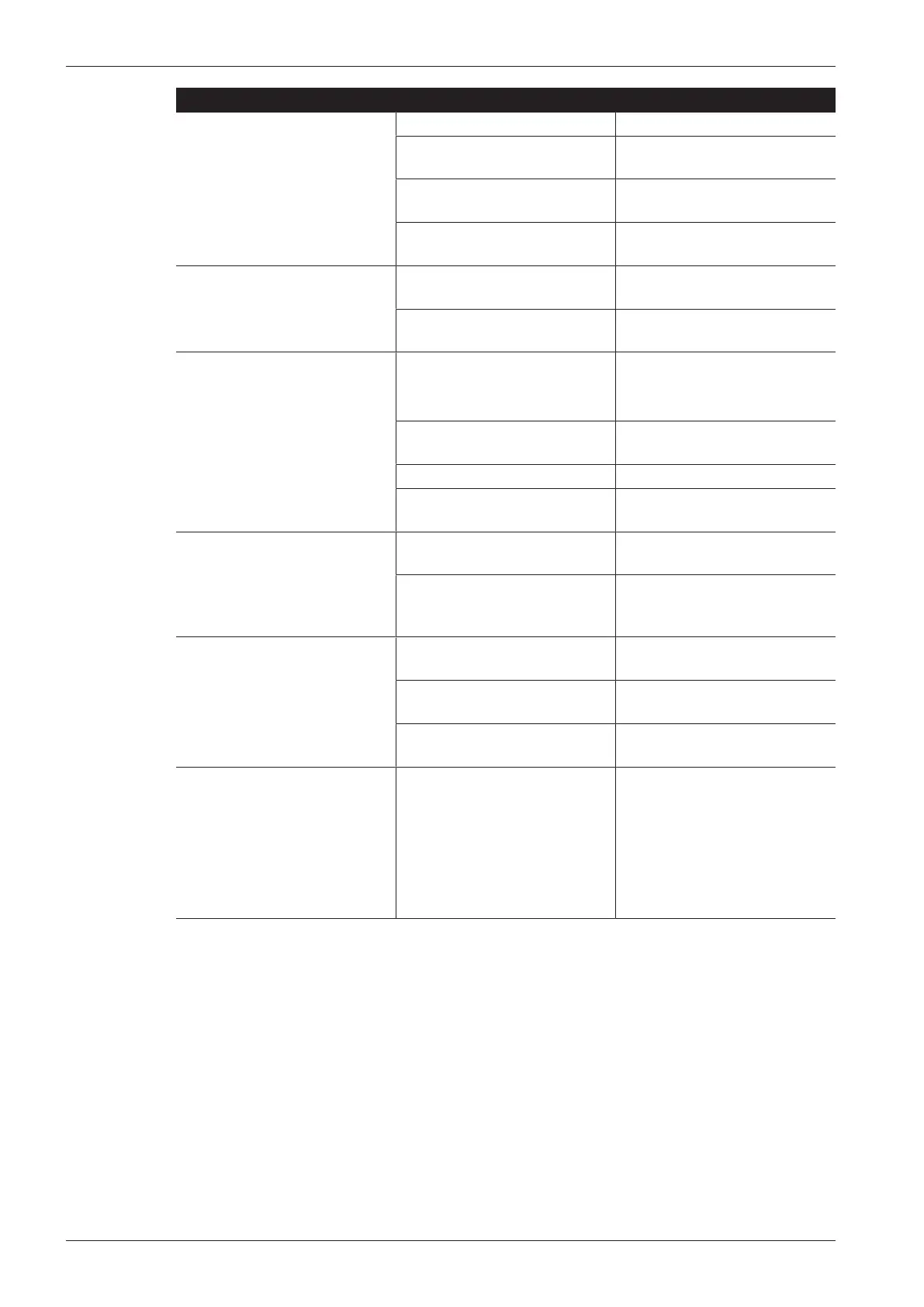

Problem Possible Cause Remedy

The machine does not reach

the usual pressure on the suc-

tion connection.

Oil level too low. ● Top up oil.

The inlet screen (IS) is partially

clogged.

● Clean the inlet screen (IS).

The inlet filter cartridge (op-

tional) is partially clogged.

● Replace the inlet filter car-

tridge.

Internal parts are worn or

damaged.

● Repair the machine (contact

Busch).

The machine runs very noisily. Stuck vanes. ● Repair the machine (contact

Busch).

Defective bearings. ● Repair the machine (contact

Busch).

The machine runs too hot. Insufficient cooling. ● Remove dust and dirt from

the machine.

● Check the cooling fan.

Ambient temperature too high. ● Observe the permitted am-

bient temperature.

Oil level too low. ● Top up oil.

The exhaust filters (EF) are par-

tially clogged.

● Replace the exhaust filters

(EF).

The machine fumes or expels

oil droplets through the gas

discharge.

The exhaust filters (EF) are par-

tially clogged.

● Replace the exhaust filters

(EF).

An exhaust filter (EF) with o-

ring is not fitted properly.

● Ensure the correct position

of the exhaust filters (EF)

and the o-rings.

The oil is black. Oil change intervals are too

long.

● Flush the machine (contact

Busch).

The inlet filter (optional) is de-

fective.

● Replace the inlet filter.

The machine runs too hot. ● See problem "The machine

runs too hot".

The oil is emulsified. The machine sucked in liquids

or significant amounts of va-

por.

● Flush the machine (contact

Busch).

● Clean the filter of the gas

ballast valve (GB).

● Modify the operational

mode (see Conveying Con-

densable Vapors [➔15]).

For the solution of problems not mentioned in the troubleshooting chart contact your Busch repre-

sentative.

Loading...

Loading...