8 | Maintenance

22 | 44 Instruction Manual TYR WT 0100-0730 CP CV_EN_en

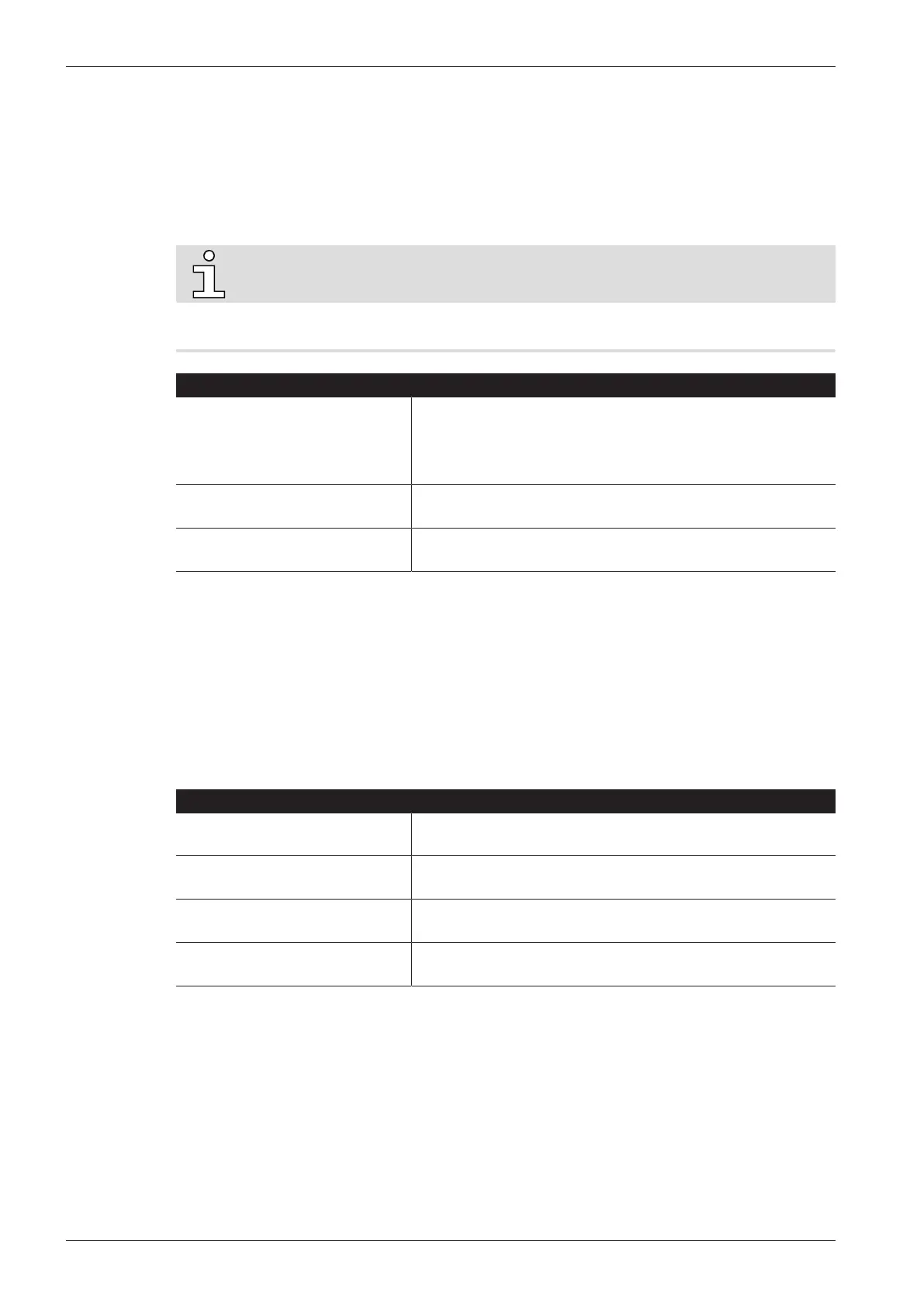

8.1 Maintenance Schedule

The maintenance intervals depend very much on the individual operating conditions. The intervals

given below are considered as starting values which should be shortened or extended as appropri-

ate. Particularly harsh applications or heavy duty operation, such as high dust loads in the environ-

ment or in the process gas, other contamination or ingress of process material, can make it neces-

sary to shorten the maintenance intervals significantly.

NOTE

The machine must be turned off at the service breaker and secured against wrongful re-acti-

vation during all service work.

Interval Maintenance work

Every 6 months ● Carry out a visual inspection and clean the machine from

dust and dirt.

● Check the electrical connections and the monitoring devic-

es.

Every 32000 hours ● Bare shaft blower overhaul or replacement is recommend-

ed.

According to the motor manual ● Check the motor. Lubricate the motor if necessary. (In ac-

cordance with the motor manual).

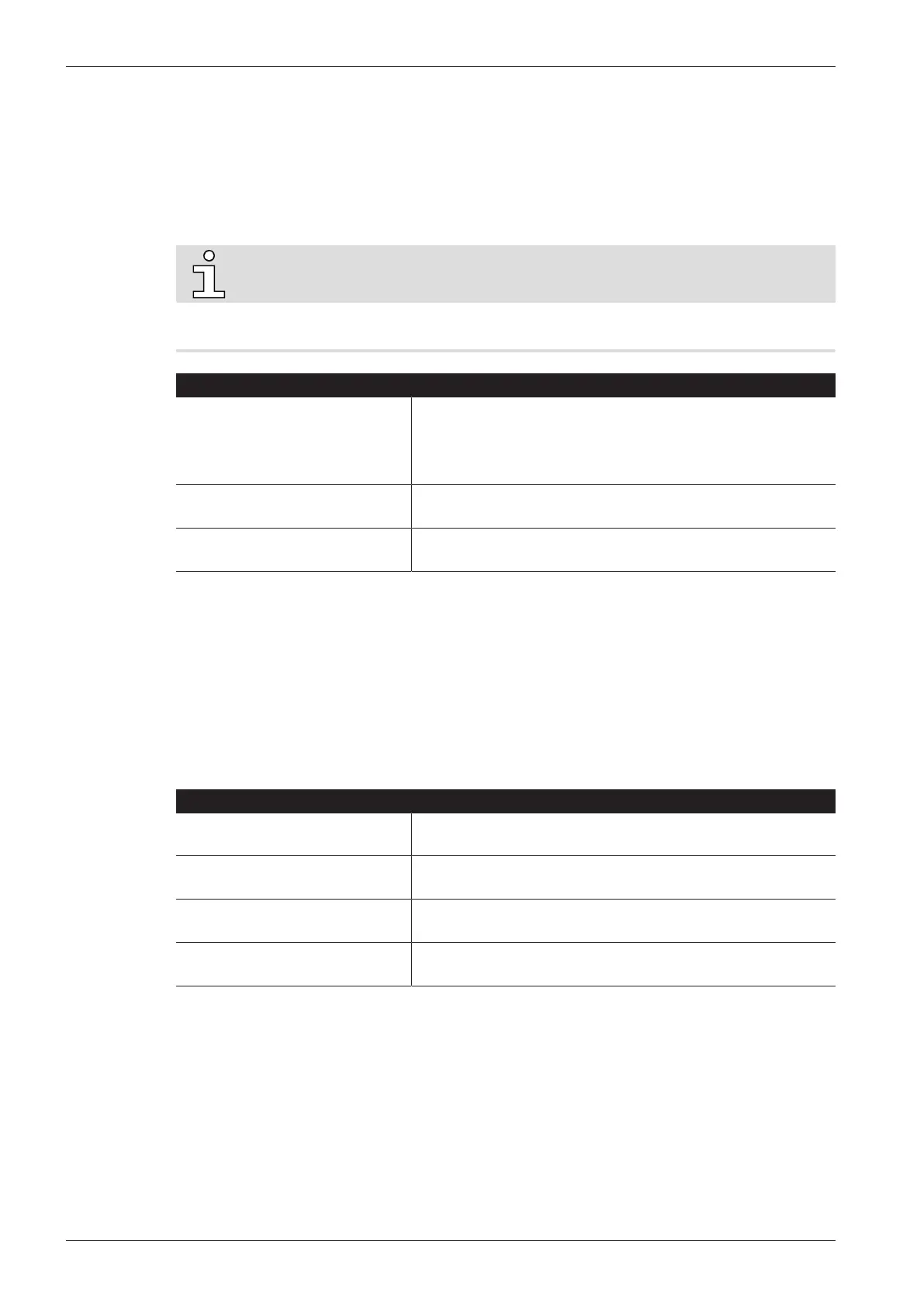

8.2 Maintenance Inlet Filter

The inlet filter must be cleaned regularly. The frequency depends on the application, but the filter

must be cleaned at least once every six months.

The filter must not be washed.

The filter’s dirt level is monitored by the supplied filter gauge that is built into the belt cover or the

cabinet front.

Cleaning with compressed air does not ensure a 100% clean wrap filter, it is therefore recommend-

ed to replace it with a new one.

Interval Maintenance work

After 10-20 operating hours ● Check the inlet filter and clean if necessary. (See clean or

change inlet filter, point 5)

Monthly (or more often depend-

ing on application).

● Check the inlet filter and clean if necessary. (See clean or

change inlet filter, point 5)

Half - yearly ● Change the inlet filter (or more often depending on applica-

tion). (See clean or change inlet filter, point 5)

Yearly ● Change the inlet filter (or more often depending on applica-

tion). (See clean or change inlet filter, point 5)

Loading...

Loading...