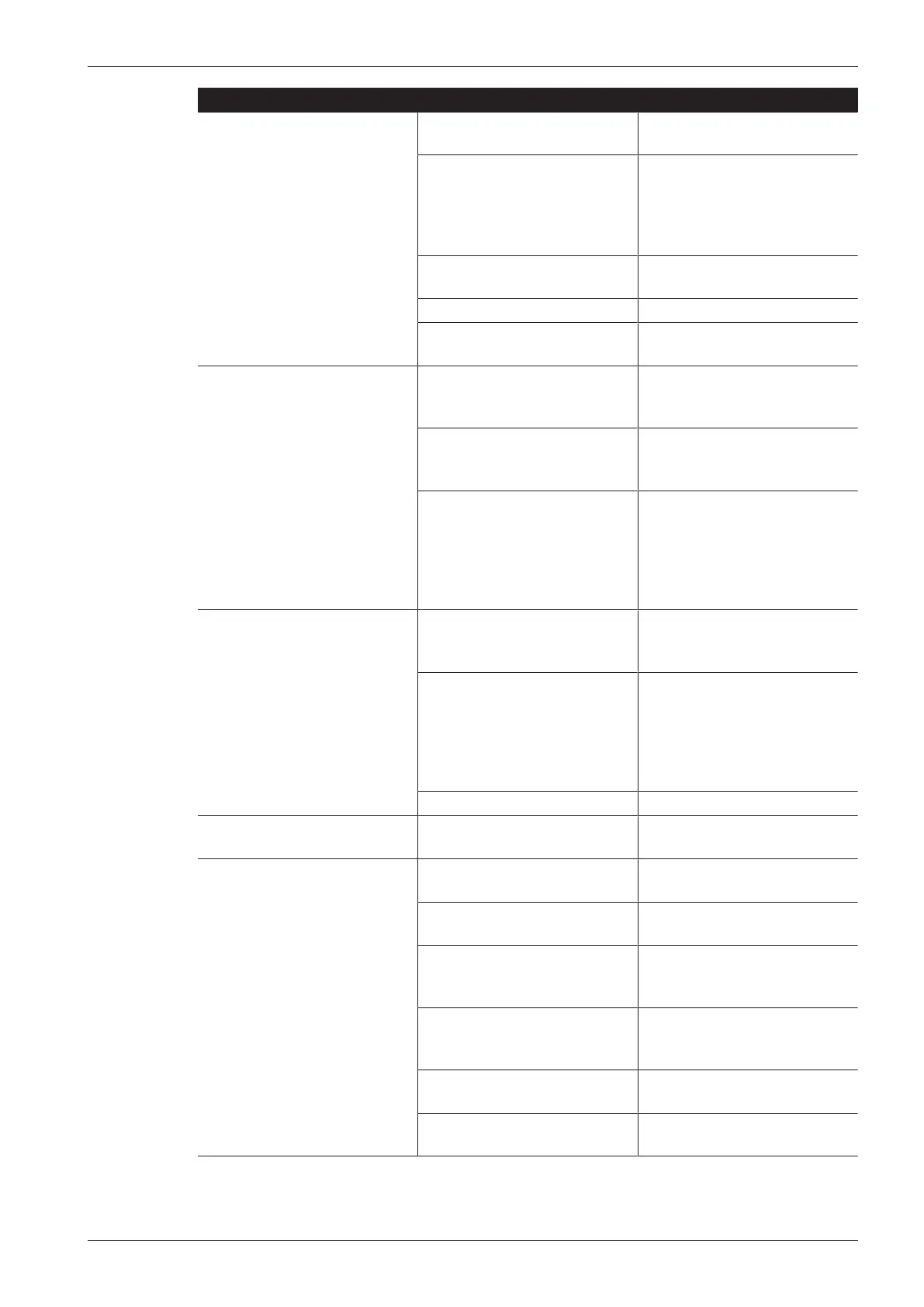

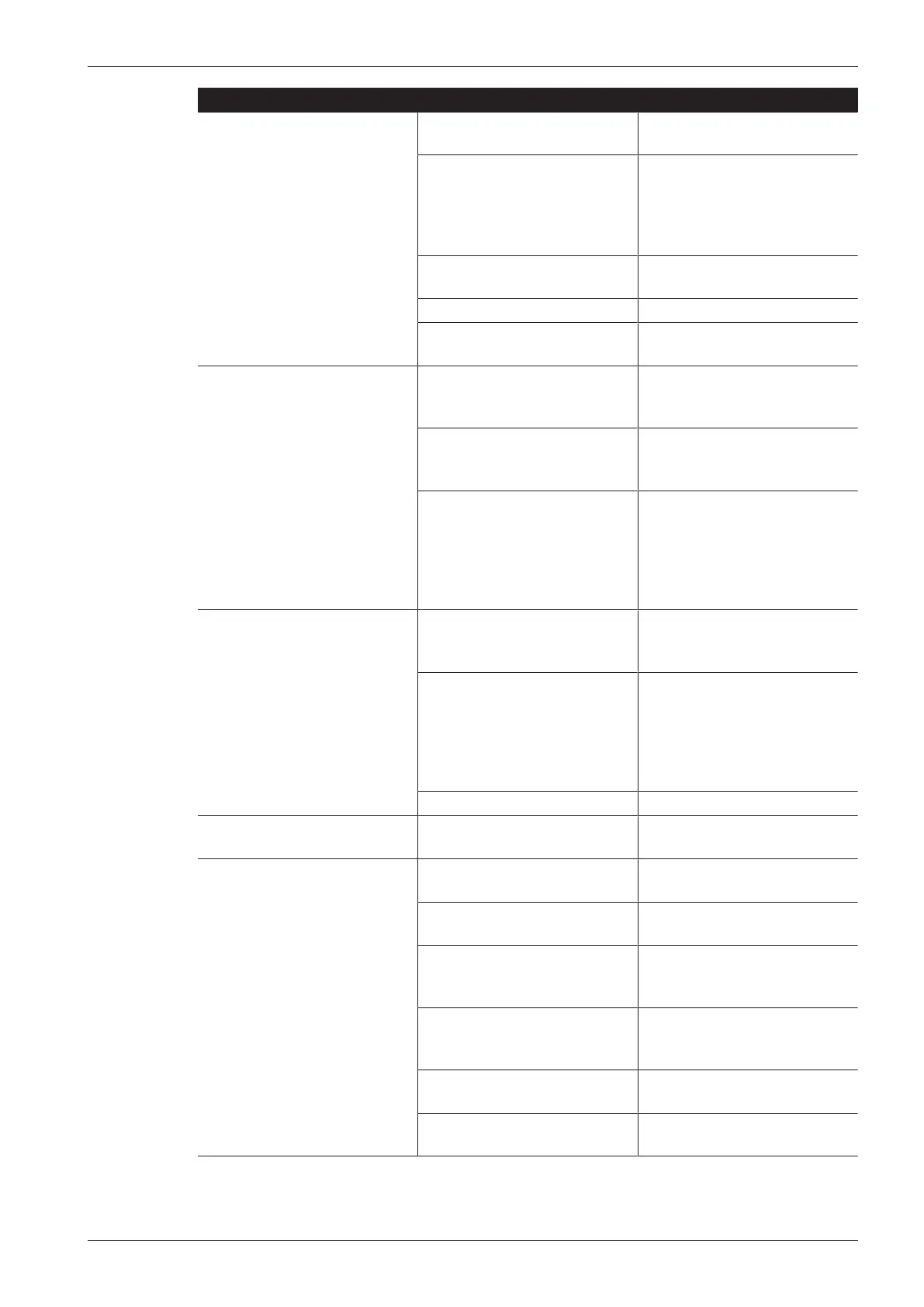

Troubleshooting | 12

Instruction Manual TYR WT 0100-0730 CP CV_EN_en 35 | 44

Problem Possible Cause Remedy

Loss of capacity. Leak in the system. ● Find the leaks and stop

them.

Activated safety valve. ● Check differential pressure

and see causes marked with

*.

Possibly set the safety

valve’s opening pressure.

Dirty inlet filter or blocked

pipes.

● Clean and possibly replace

filters and pipes.

Loose belts. ● Replace belts.

Too high differential pres-

sure*.

● See symptoms and causes

marked with *.

Continuously activated safety

valve.

Too high rpm and thereby too

high amount of air (concerns

frequency-controlled blowers).

● Lower the rpm.

Too high differential pressure* ● Find the cause of the in-

creased differential pressure

and repair it.

The valve setting is below the

actual operating point.

● Adjust the max limits of fthe

valve within the blower.

Monitor the absorbed pow-

er and ensure that the set-

ting does not allow over-

loading of the pump.

Abnormally high differential

pressure*

STOP THE MACHINE IMMEDI-

ATELY !

Safety valves do not open de-

spite too high differential pres-

sure.

● Dismantle and clean valve

and possibly readjust.

Blockages on inlet side or out-

let side of the blower.

● Clean the pipe system and

look for mechanical or con-

trol system related blockag-

es or obstructions that can

lead to increased loss of

pressure.

Fault on check valve. ● Replace check valve.

The motor is running the

wrong way.

Wrong power supply. Switch two phases to reverses

the direction of revolutions.

Abnormal motor temperature. Motor fault or fault in motor

bearings.

● Repair and replace the mo-

tor.

The motor is incorrectly electri-

cally wired.

● Check and reconnect.

Overloading. ● Look for causes of increased

differential pressure in the

system and repair.

Wrong power supply. ● The power supply must be

consistent with data on mo-

tor’s type sign.

Too high ambient temperature

(+40°C).

● Improve ventilation in the

machine room.

Fault on motor fan. ● Repair and replace the mo-

tor fan.

Loading...

Loading...