Hi Flow Stroller Technical Service Manual • PN 14314465 Rev F

17

Hi Flow Stroller

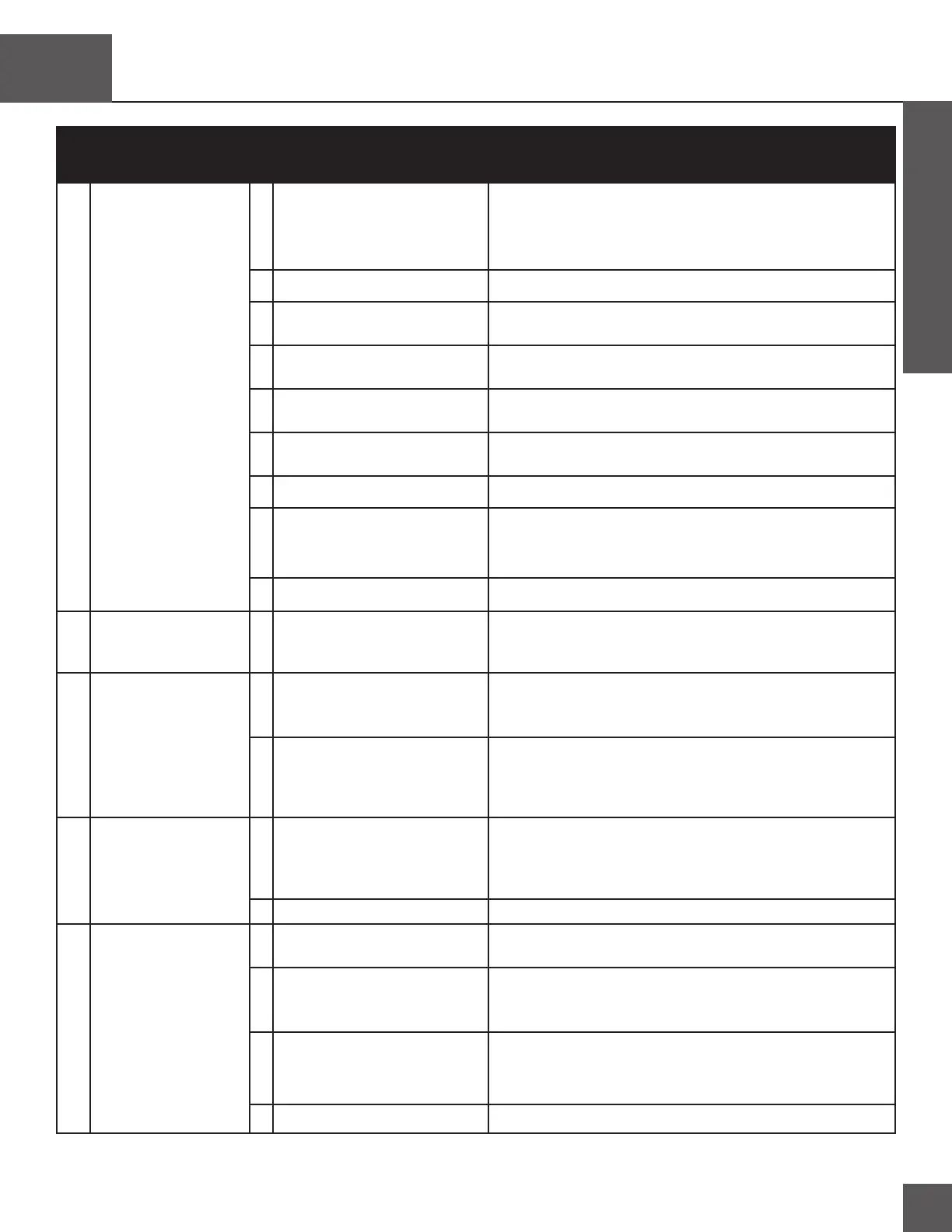

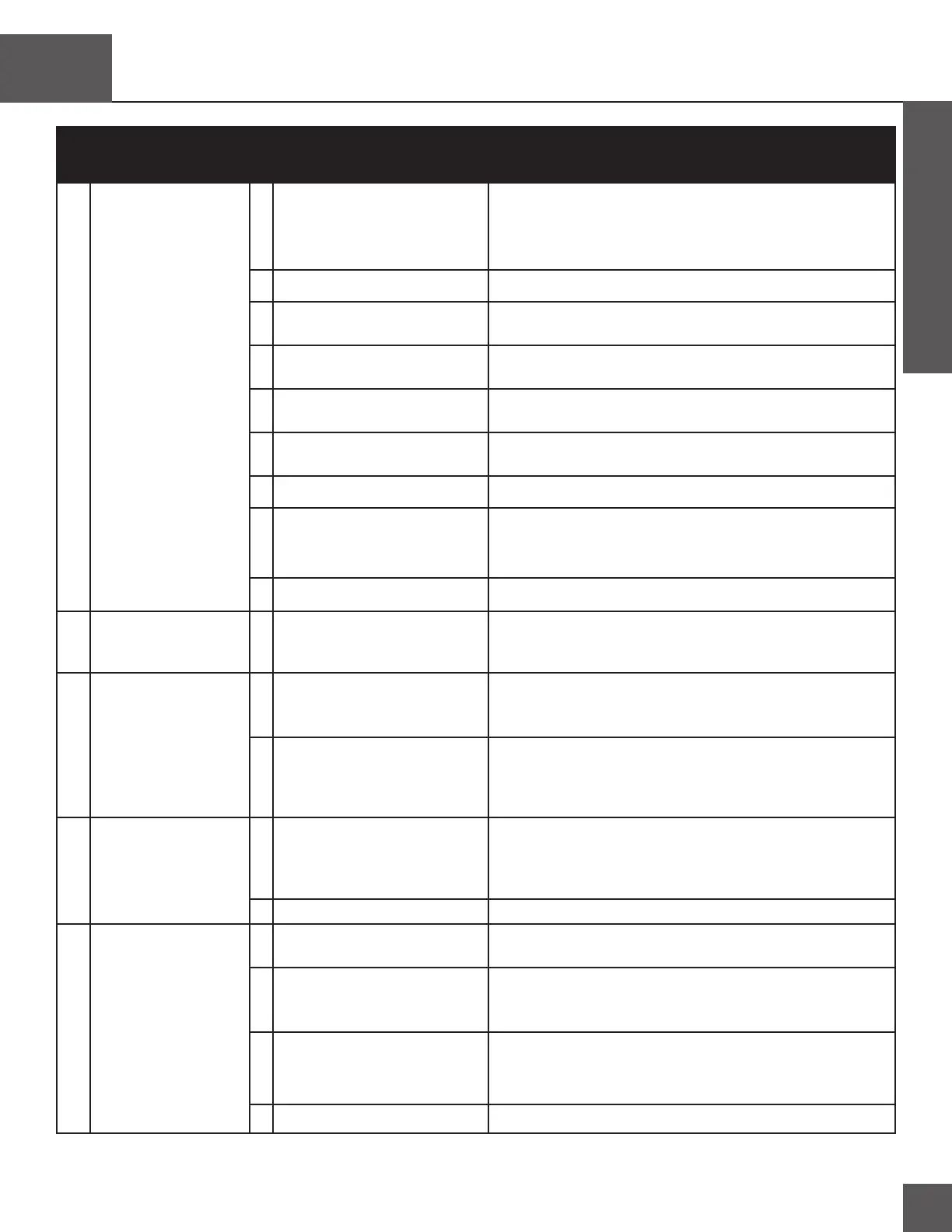

Troubleshooting Chart

X

Symptom Probable Cause Corrective Action

1) Unable to start fill or

excessivly long fill times

a) QDV not properly engaged on

the reservoir

Make sure the QDV on the portable and reservoir are properly

aligned. Ensure that a downward force is being applied to the

portable for top fill. Ensure the portable is completely engaged

for side fill.

b) Reservoir is empty Swap or re-fill the reservoir

c) Vent valve not open Ensure that the vent valve lever is fully in the open position.

The lever must be open to begin a fill.

d) FCV is open Be sure that the FCV knob is in the off (“0”) position. If the

valve is open, fill times can increase.

e) Reservoir saturation pressure is

too low

Swap reservoirs or allow the reservoir time to stabilize and build

pressure

f) Vent valve is obstructed Inspect the vent tubes for blockages. Clean by blowing out with

compressed gas or replace parts if necessary.

g) Leak in the system Check the portable for leaks (RP18) and repair if needed.

h) QDV damaged or faulty Inspect the QDV and be sure the poppet opens properly and

smoothly. If necessary, replace the QDV (RP15 or RP16)

i) Faulty vent valve Replace the vent valve (RP19)

2) Liquid leaks from the

coupled QDVs during

the fill

a) Worn or damaged lip seal Replace the QDV lip seal if top fill (RP16). See reservoir techni-

cal manual for replacement of side fill lip seal on reservoir.

3) Unable to disconnect

the portable from the

reservoir

a) Pop-off assembly not being uti-

lized (Top fill only)

Ensure that the pop-off assembly on the reservoir is being used

(top fill only). Do not use force to separate the QDVs on top fill

or side fill.

b) QDVs are frozen together Leave the units coupled with the vent valve closed and let them

sit until they warm up enough to disconnect. Always ensure

that male and female QDV’s are cleaned and dried prior to each

fill.

4) Liquid leaks from the

QDV poppet after fill-

ing

a) Ice crystal preveting the QDV

from closing properly.

Engage and disengage the portable onto the reservoir several

times to dislodge the ice crystal. Always be sure that the male

and female QDVs are wiped clean and dry before filling.

b) Dirty or damaged QDV poppet Replace the QDV (RP15 or RP16)

5) Liquid leaks from the

vent valve tube/outlet

a) Vent valve is not fully closed Ensure that the vent valve lever is fully in the closed position.

b) The portable has been trans-

ported or laid in an improper

operating position

Return the portable to an upright or acceptable operating posi-

tion and allow several minutes for stabilization.

c) Vent valve is frozen open Allow the portable to warm until the vent valve can close. After

the warm up, allow up to 60 minutes for the portable to stabilize

and build pressure before operating.

d) Faulty vent valve Replace the vent valve (RP19)

Loading...

Loading...