www.came.co.uk Helpline Tel: 0870 012 9000 - 3 -

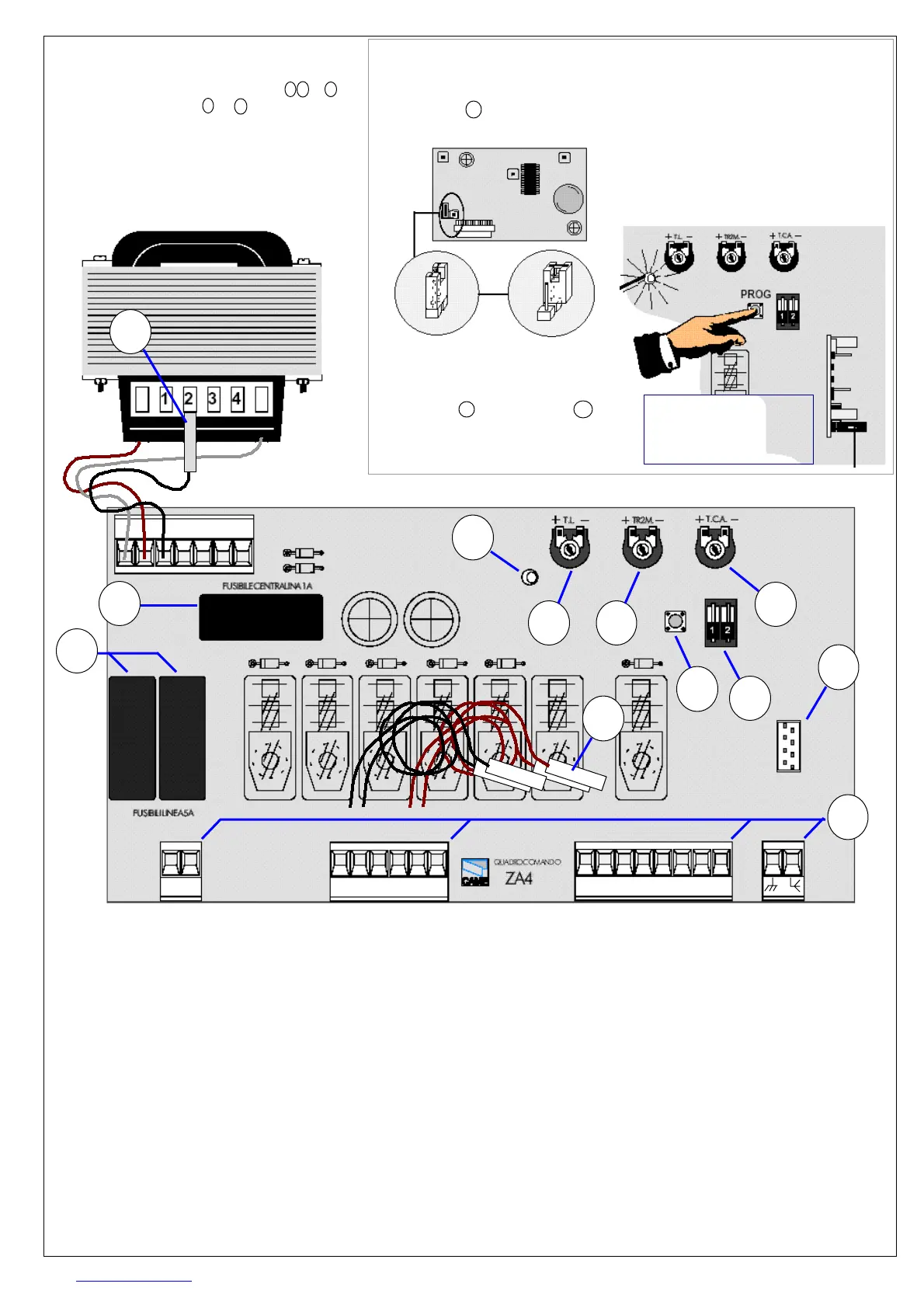

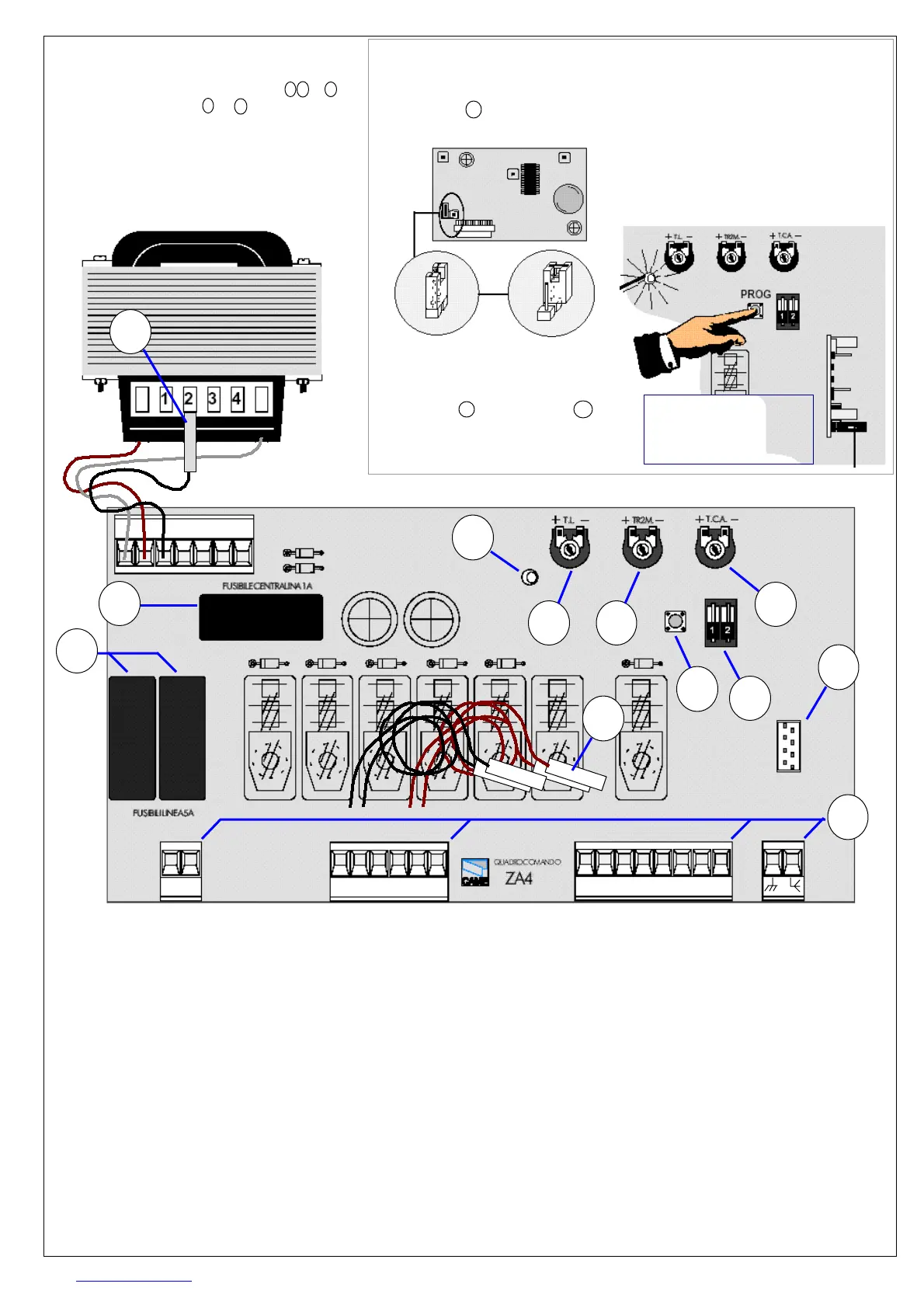

MAIN COMPONENTS

1. Connectors

2. Mains fuses, 5A

3. Accessory fuse, 1.6A

4. Programme button

5. Run time adjustment

6. Interleaf delay

7. Open period

8. Programme DIP’s

9. Radio head plug

10. Indicator LED

11. Torque setting

12.

Capacitor cables

10 11 1 2 3 5 7 C1

U V W X Y E1

1

2

3

7

65

8

9

4

10

L1 L2

12

11

TORQUE SETTING c2

The power of the motor is set on the

transformer. A black wire connects to

the transformer in one of 4 positions

by a white fast-on connector. Select

the lowest setting (

from 1 to 4

) that will

ensure reliable satisfactory operation.

RUN TIME SETTING c3

The motor running time is set by ‘TL’

(

adjustment 5

). Set such that the motor

with the longest travel arrives 2 secs

before the motor switches off. Run

time is less important on motors with

limit switches. The overrun time will

be added to the open period.

INTERLEAF DELAY c4

This allows overlapping gate leaves

to close in the right order by applying

a delay before closing motor 2 (

WXY

)

AUTOMATIC CLOSING c5

Auto-closing is enabled by switching

DIP 2 on (up) on switch block 8. The

gates re-close from 1 to 60 sec after

opening. The open period is set on 7.

The LED indicator flashes once per

second during the open period.

Motor Connector

Control Connector

Mains in Aerial

Changes should be made by competent

persons only. Always disconnect power

before making any wiring changes.

TRANSMITTERS

The TOP432s code is set on switches

inside the transmitter. We recommend

changing the code from that supplied.

To copy a code to a new transmitter,

set the switches until they match.

RADIO CODE SETTING c1

The AF43 radio head plugs onto the

ZA4 board at 9 . Ensure the jumper is

set correctly on both pins. See below:

RECEIVER SETTING

The ZA4 holds the radio code in flash

memory. To set a code, press & hold

prog button 4 . The red LED 10 will

flash. Now press the radio transmitter

button as well. The LED will light con-

stantly until both buttons are released.

COMMISSIONING

The system must be wired fully. Turn 5 6 & 7

fully anticlockwise, then 5 & 7 clockwise by

90

0

. Set the transformer torque to position 1.

Follow commissioning route from c1 to c5. On

FROG systems, read guide T6 for setting the

motor direction.

1- Hold prog button

2- Press transmit

3- Let go both

Loading...

Loading...