ENGINEERED & PROCESS VALVES

02/2011 / IOM-WKM-GATE-PRS-01

13

Installation, Operation and Maintenance Manual

LUBRICATING HANDWHEEL AND OPERATOR ASSEMBLY

Handwheel Operated Valves - Connect a grease gun

containing NLGI grade 2 petroleum base grease to

the 1/8” Alemite type grease fitting on the bearing

housing. Pump in a small amount of grease. DO NOT

OVERFILL.

Bevel Gear Operated Valves - Bevel gears are supplied

by other manufacturers. Consult particular

manufacturer’s instructions. If these are not available,

lubricate the same as Handwheel Operated Valves

above.

Motor Operated Valves - Motor operators are

supplied by other manufacturers. Consult particular

manufacturer’s instructions. Lubricating Seats (6” and

larger valves equipped with seat sealant ports).

Lubricate once a year.

1. Only use grease guns that are equipped with a

pressure gage.

2. Some seat sealants become very stiff or viscous

in cold weather. It may be difficult to pump

some sealants under these conditions.

It is recommended that the grease gun

be kept in a heated area until it is ready to be

used. If this is not possible, contact your local

Cameron Valves & Measurement

representative for low temperature sealant

recommendations.

3. Move the valve to the closed position.

4. Carefully, remove the safety caps on the seat

lubrication fitting using a wrench.

Warning: Back-up the seat grease fitting using a

wrench so only the safety cap will be removed from

the fitting. Carefully remove the safety cap from the

seat grease fitting. NEVER remove the grease fitting

with the valve under pressure!

5. Connect the grease gun to the seat lubrication

fitting(s). (Both sets may be lubricated at the

same time)

6. Pump the sealant into the seat. Once the

pressure rises above the valve rated pressure,

hold for three (3) minutes to promote filling

of the grease grooves.

NOTE: Grease guns can develop pressures far in

excess of the valve working pressure. Use only grease

guns, which are equipped with pressure gages. Do

not exceed the valve maximum allowable

working pressure.

7. Stroke the valve to spread the sealant on the

seat surfaces. (Indicator rod should move

approximated 1” or 25 mm.)

8. Release the pressure in the grease gun and

remove it from the grease fitting. The fitting

ball check should prevent the release

of the valve grease pressure.

9. Install the fitting safety cap and

tighten securely.

10. Repeat for the other seat. Both seats may be

lubricated at the same time, if desired.

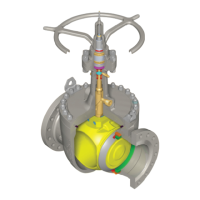

RECOMMENDED LUBRICANT & SEALANT

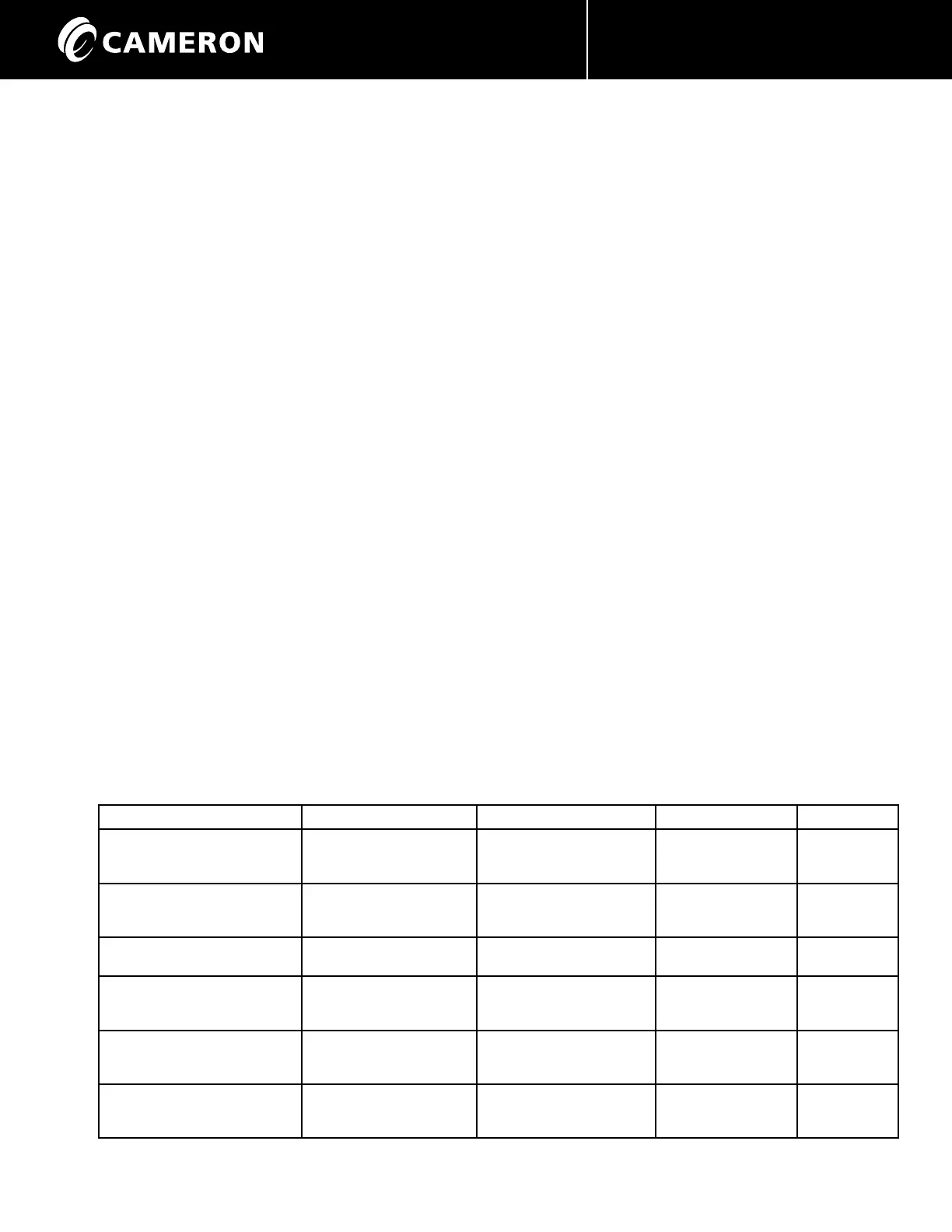

Trim Normal Seat Lubricant Emergency Seat Sealant Bearing Lubricant Stem Packing

T-11, T-102, T-94

(Aromatic Hydrocarbons and

refined products)

WKM #58G

or VAL-TEX 700

WKM #58G NLGI Grade 2

Bearing Grease

WKM #113

or JIM RAY

TIGER PAK FF

T-24, T-10

(Sour Oil and Gas,

Waterflood)

VAL-TEX 700 WKM #102 NLGI Grade 2

Bearing Grease

WKM #109

T-08, T07

(Geothermal water and Steam)

NONE NONE NLGI Grade 2

Bearing Grease

WKM #115

T-30, T-31

(High temperature steam and

hydrocarbon products)

NONE NONE NLGI Grade 2

Bearing Grease

NONE

T-36, T-37

(Low temperature produced

hydrocarbons)

VAL-TEX 50 WKM #103 WKM #1 WKM #109

T-88

(Anhydrous Ammonia Products)

NLGI Grade 2

Bearing Grease

NLGI Grade 2

Bearing Grease

NLGI Grade 2

Bearing Grease

JIM RAY

TIGER PAK A

Loading...

Loading...