2

Scope

ENGINEERED VALVES

One of the most trusted valves in the petroleum

industry, the CAMERON T31 Fully Welded Body Ball

Valve combines the strength of forged components

with a lightweight and compact spherical design.

CAMERON T31 Fully Welded Body Ball Valves

satisfy ASME 150 through 2500 (PN 20 through

PN 420) and API 2000 through 10000 standards.

Made of forged steel to assure uniform fine grain

structure and toughness, they may be specified

in sizes from 2" to 56" (DN 50 to DN 1400).

Engineered for heavy-duty

maintenance, the CAMERON T31 Fully Welded

Body Ball Valve is commonly selected for a

number of applications. The distinctive design of

the CAMERON T31 Fully Welded Body Ball Valve

gives it maximum strength and minimum weight

as well as maximum resistance both to pipeline

pressure and stresses. The compact, spherical

design also eliminates body flanges, thus reducing

overall size and leak paths.

service and minimal

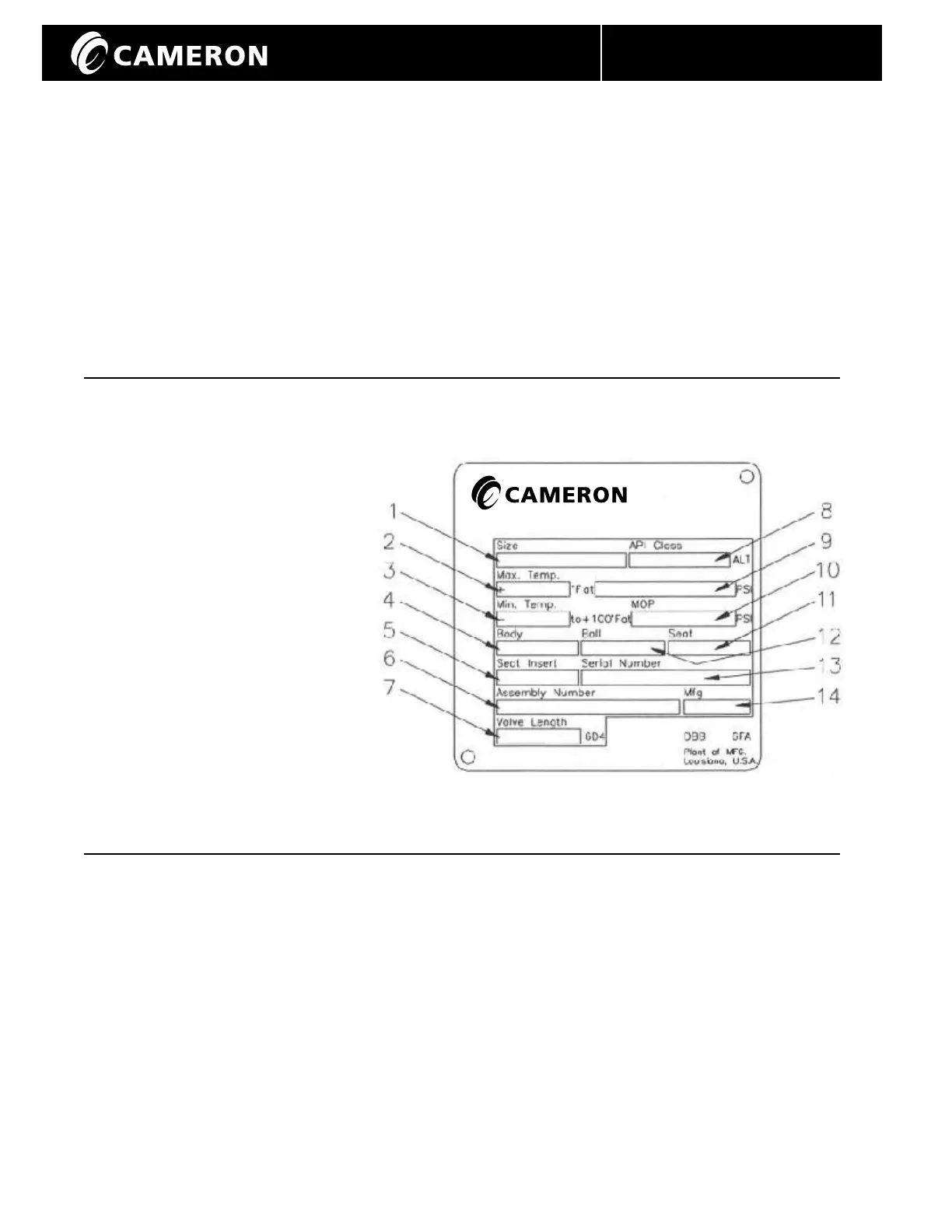

Nameplate Information

ITEM STAMP

1 Nominal Valve Size x Actual Bore Size.

2 Maximum Temperature

3 Minimum Temperature

4 Body Material Symbol

5 Seat Insert Material Symbol

6 Assembly Part Number

7 Valve Length

8 API Class Designation

9 Maximum Working Pressure

10 Maximum Operating Pressure

11 Seat Material Symbol

12 Ball Material Symbol

13 Valve Assembly Serial Number

14 Month and Year of Manufacture

Storage

The valves are conditioned for a storage period of

approximately six months. The following care should

be taken when storing valves.

1. Make sure the valve end connection covers remain

in place during storage.

2. If the valve does not have an operator already

installed and the valve will be stored outside, the

open stem extension or the stem adapter should

be covered to avoid water buildup.

3. If long-term storage is required, the valve

should be conditioned using a corrosion

inhibitor and end connection covers.

Follow the guidelines found in CAMERON

Engineering Bulletin 476B for long term

storage.

Obtain a copy from your Cameron Valves &

Measurement representative.

Figure 2 - Typical Valve Nameplate.

Installation, Operation and Maintenance Manual IOM-CAM-BALL-T31

Loading...

Loading...