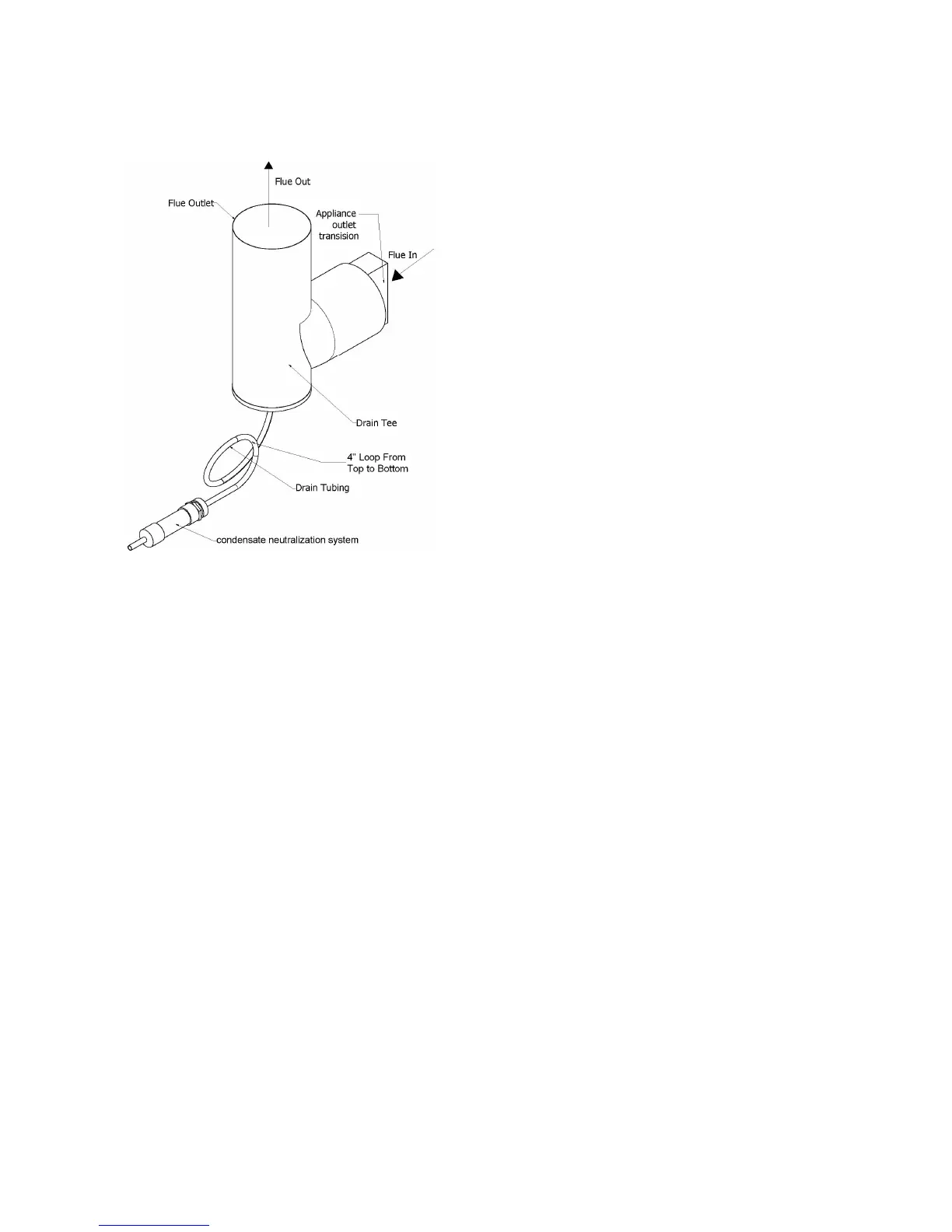

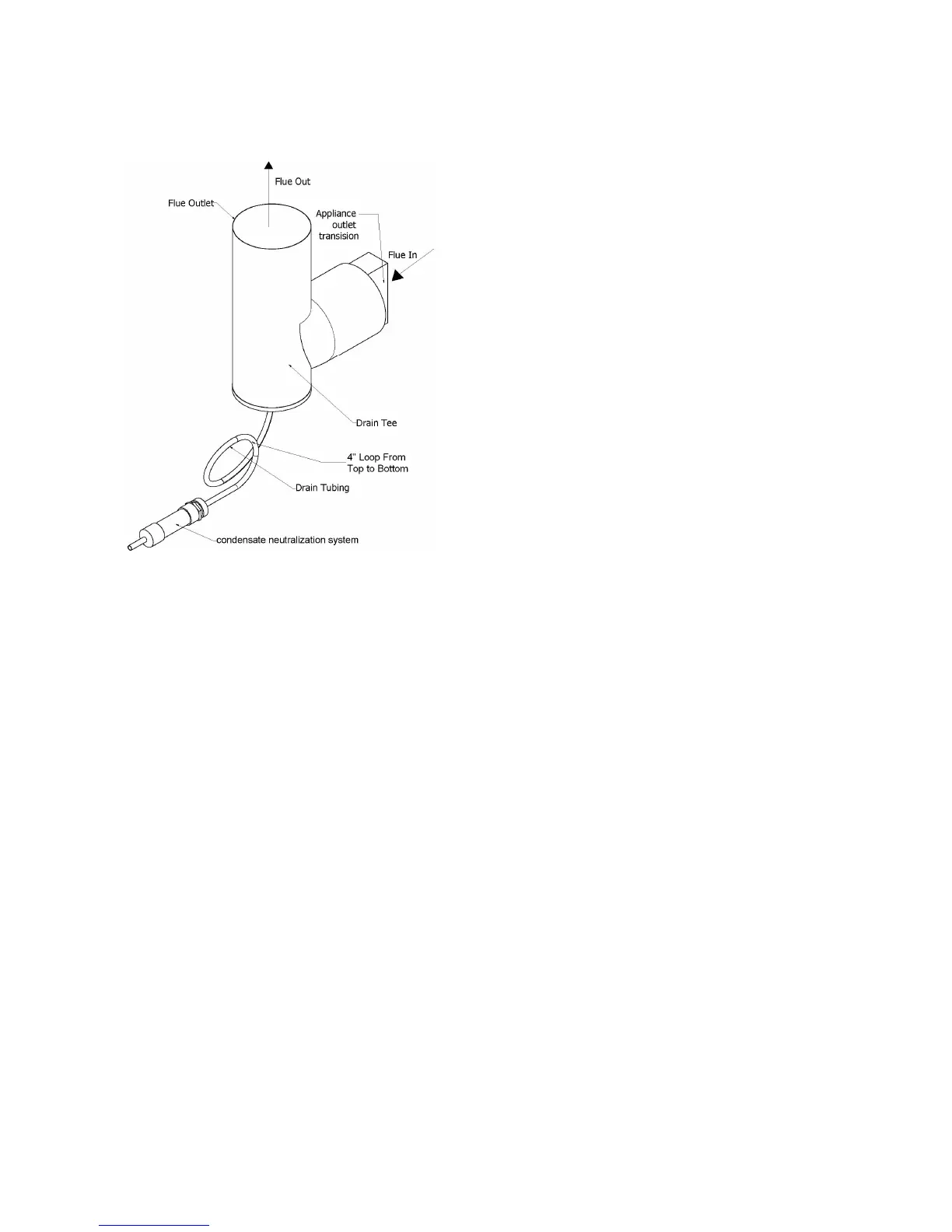

2.1.13 DRAIN TEE

Figure 7: Drain “T” and Neutralizer Cartridge Installation

A drain tee MUST be installed in the Condensing vent pipe to

collect and dispose of any condensate that may occur in the

vent system. The drain tee should be installed at the point

where the flue turns vertical for a roof top termination or as one

of the first fittings in a horizontal flue that will terminate on a

THRUWALL. Ensure that horizontal portions of the vent are

properly sloped to allow condensate to be evacuated at the

drain tee. Plastic drain tubing, sized per the vent

manufacturer’s instructions, shall be provided as a drain line

from the tee. The drain tubing must have a trap provided by a

4" (10cm)-diameter circular trap loop in the drain tubing. Prime

the trap loop by pouring a small quantity of water into the drain

hose before assembly to the vent. Secure the trap loop in

position with nylon ties. Use caution not to collapse or restrict

the condensate drain line with the nylon wire ties. The

condensate drain must be routed to the condensate

neutralization system or a suitable drain for disposal of

condensate that may occur in the vent system.

Ensure that the drain from the condensate tee is not exposed

to freezing temperature.

2.2 CONVENTIONAL VENTING (INDOOR)

INSTALLATIONS

• NON – CONDENSING

• The DynaFlame® non-condensing is a category I

appliance and is approved for venting into a common

standard chimney. On single appliance installations with

dedicated chimney if drafts are excessive (above negative

0.15 Inches W.C.), install a single acting barometric

damper directly past the appliance’s flue outlet. A

minimum draft of 0.05 Inches W.C is required for

operation. This damper will control excessive draft &

minimize standby losses.

• Multiple appliances may be vented into a conventional

chimney. The chimney must be lined. And a single acting

barometric damper must be provided for each appliance.

Vent diameters are to be increased over and above

those recommended in Table 5.

• The chimney must be protected from down drafts, rain

and debris by using a listed chimney cap.

• If the appliance is located in a room maintained at low

temperature and is being run for extended periods of

time at low fire it is likely that condensation will be

formed in the vent. Consideration must be given to

heating the room or providing a special venting

system similar to that used for condensing appliance

application

• CONDENSING

• The DynaFlame® condensing version is a category II

appliance and is approved for venting into a common

properly designed chimney. On single appliance

installations with dedicated chimney, if drafts are

excessive (above negative 0.15 Inches W.C.), we

recommend a single acting barometric damper.

• A qualified professional using a proven vent-sizing

program with input of accurate operating parameters

must properly do sizing of the venting system. In

applications where flue gas temperatures are lower

than can support a Category II with conventional

negative draft, it will be determined at the venting

design stage that a positive pressure will be

developed in the vent. It will then be necessary to

either provide separate vents as for Category IV,

pressurize the room or to provide an extractor at the

chimney outlet interlocked with the appliance

operating circuit in order to maintain a negative draft

in the chimney and allow common venting.

• Approval of the installation will be at the discretion of

authorities having jurisdiction.

• IN GENERAL

• The operation of exhaust fans, compressors, air

handling units etc. can rob air from the room, creating

a negative pressure condition leading to reversal of

the natural draft action of the venting system. Under

these circumstances an engineered air supply is

necessary.

• If the appliance is to be installed near a corrosive or

potentially corrosive air supply, the appliance must be

isolated from it and outside air should be supplied as

per code.

• Potentially corrosive atmospheres will result from

exposure to permanent wave solution, chlorinated

waxes and cleaners, chlorine, water softening

chemicals, carbon tetrachloride, halogen based

refrigerants, Freon cleaning solvents, hydrochloric

acid, cements and glues, masonry washing materials,

antistatic fabric softeners, dry cleaning solvents,

degreasing liquids, printing inks, paint removers, etc.

• The equipment room MUST be provided with properly

sized openings to assure adequate combustion air

and proper ventilation when the unit is installed with a

proper venting system.

Loading...

Loading...