3.2 GAS PIPING

All gas connections must be made with pipe joint compound

resistant to the action of liquefied petroleum and natural gas.

All piping must comply with local codes and ordinances.

3.3 INSTALL PIPING

• The gas line should be sufficient to handle the total

installed capacity. Verify pipe size with gas supplier.

• Use new, properly threaded black iron pipe free from

burrs. Avoid flexible gas connections. Internal diameter of

flexible gas lines may not provide appliance with proper

volume of gas.

• Install a manual main gas shutoff valve at the appliance

gas inlet, outside of the appliance and before the gas

valve. Install a joint union at the appliance gas line

connection for ease of service and removal of the gas

train.

• Run pipe to the Appliance gas inlet.

• Install a sediment trap in the supply line to the Appliance

gas inlet.

• Apply a moderate amount of good quality pipe compound.

• For LP gas, consult your LP gas supplier for expert

installation.

The appliance and its individual gas shut-off valve must be

disconnected from the supply piping when pressure testing the

gas supply piping at pressures above ½ PSI

Table 7: Gas Pressures at Inlet to Appliance

11 14

* 3” for 500 and 750 models. 3.5” for 1100 and 1200 models.

4.5” for models 1500 – 6000. Recommended regulator

settings is 7.0” w.c

The gas supply line must be of adequate size to prevent undue

pressure drop and must never be smaller than the size of the

connection on the appliance. Sizing based on Table 7 is

recommended.

Before operating the appliance, the complete gas train and

all connections must be tested using soap solution.

Verify that the appliance is supplied with the type gas

specified on the rating plate. Heating values of local

natural gas are to be between 950 and 1010 Btu/ft

3

.

Consult factory if heating values are outside this range or

if a gas with a mixture of constituents is being used.

3.4 AIR/GAS RATIO VALVE

The main gas valves supplying gas to the burner for

models 2000 to 5000 on this appliance utilize a servo

pressure regulator providing a slow opening, fast closing

safety shut off and an air/gas ratio control valve for the gas

combustion process. This gas valve controls the pressure

difference across the flow orifice in the manifold supply

line as a function of the pressure difference across the

combustion air supply to the burner. The actuator

maintains a constant air to gas ratio as the volume of air

changes based on the operation of the combustion air fan.

The valve is a 1:1 differential pressure air/gas ratio

controller. The valve generates the same pressure

difference on the gas side as it senses on the air side.

Models 500 to 1750 utilize a 1:1 ratio dual seat negative

pressure gas valve. Models 2000 – 3000 utilize a 1:1

air/gas ratio control valve and a safety solenoid valve.

Models 3500 – 6000 utilize a 1:1 air/gas ratio control and

regulating gas valve. The regulating gas valve performs

the functions of a pressure regulator, safety shutoff. Full

closing of the valve seat occurs in less than 0.8 seconds

when the valve is de-energized. Operation of the gas

valve in combination with the combustion air fan allows the

burner input rate to vary from 20% to 100% based on

temperature demand. The inlet gas supply pressure must

be maintained within the specified minimum and maximum

pressures.

The air/gas ratio is preset at the factory and adjustment is

not usually required if gas supply pressure is maintained

within the specified range.

There are no serviceable parts on the dual seat negative

pressure air/gas ratio valve control.

A reduction of up to 30% is permitted in the inlet gas

pressure between light off and full fire conditions.

If the manifold differential pressure is to be measured,

refer to section 3.8 Checking Differential Air and Gas

Pressures for proper measurement.

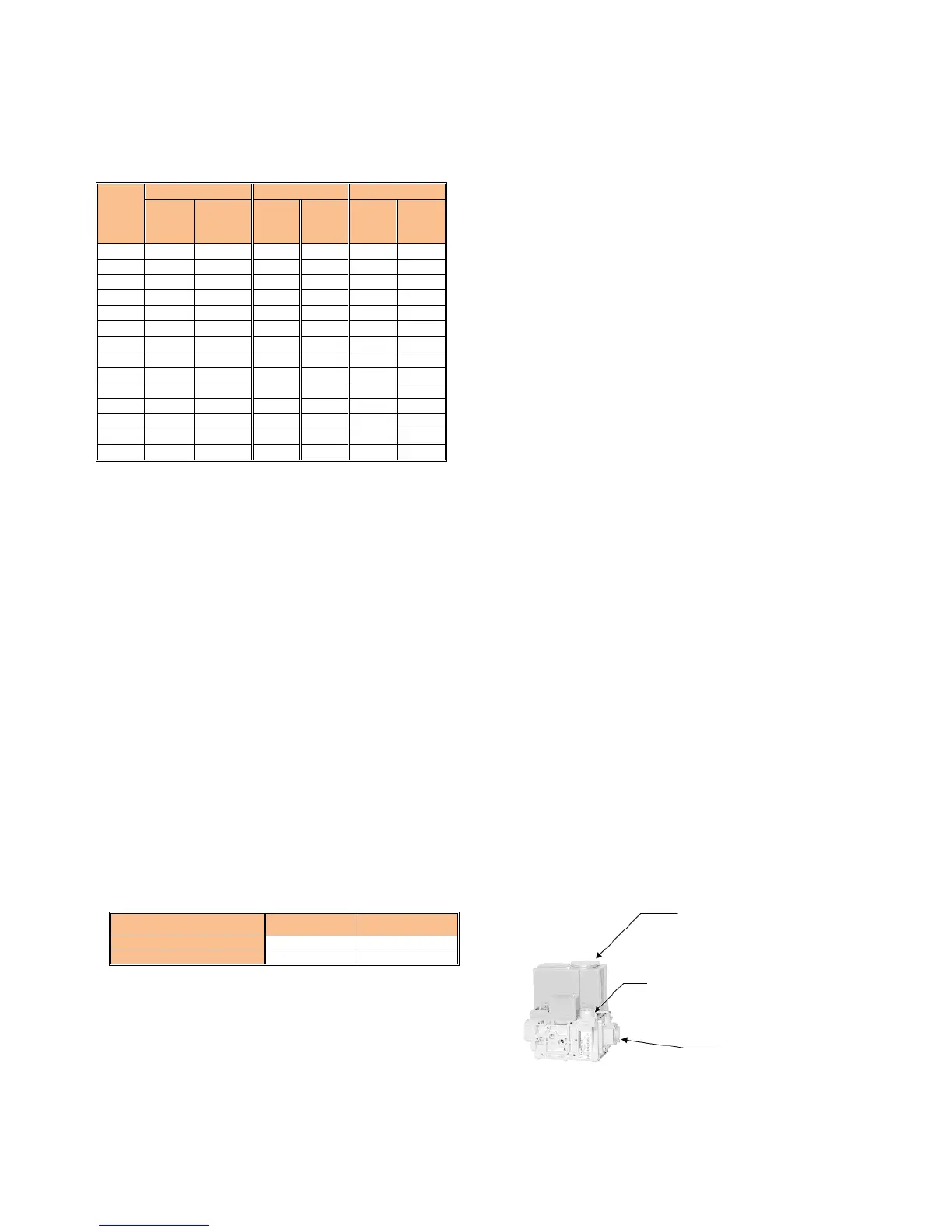

Figure 8: DF500 – 1750 1:1 Negative Pressure Air Gas

Ratio Control Valve

Lift top cover to access high fire

air/gas ratio adjustment

(use 3mm allen key for adjustment,

counter-clockwise increases CO

2

)

Low fire air/gas ratio adjustment

(use T-40 for adjustment,

clockwise increases CO

2

)

Gas Inlet

Loading...

Loading...