23

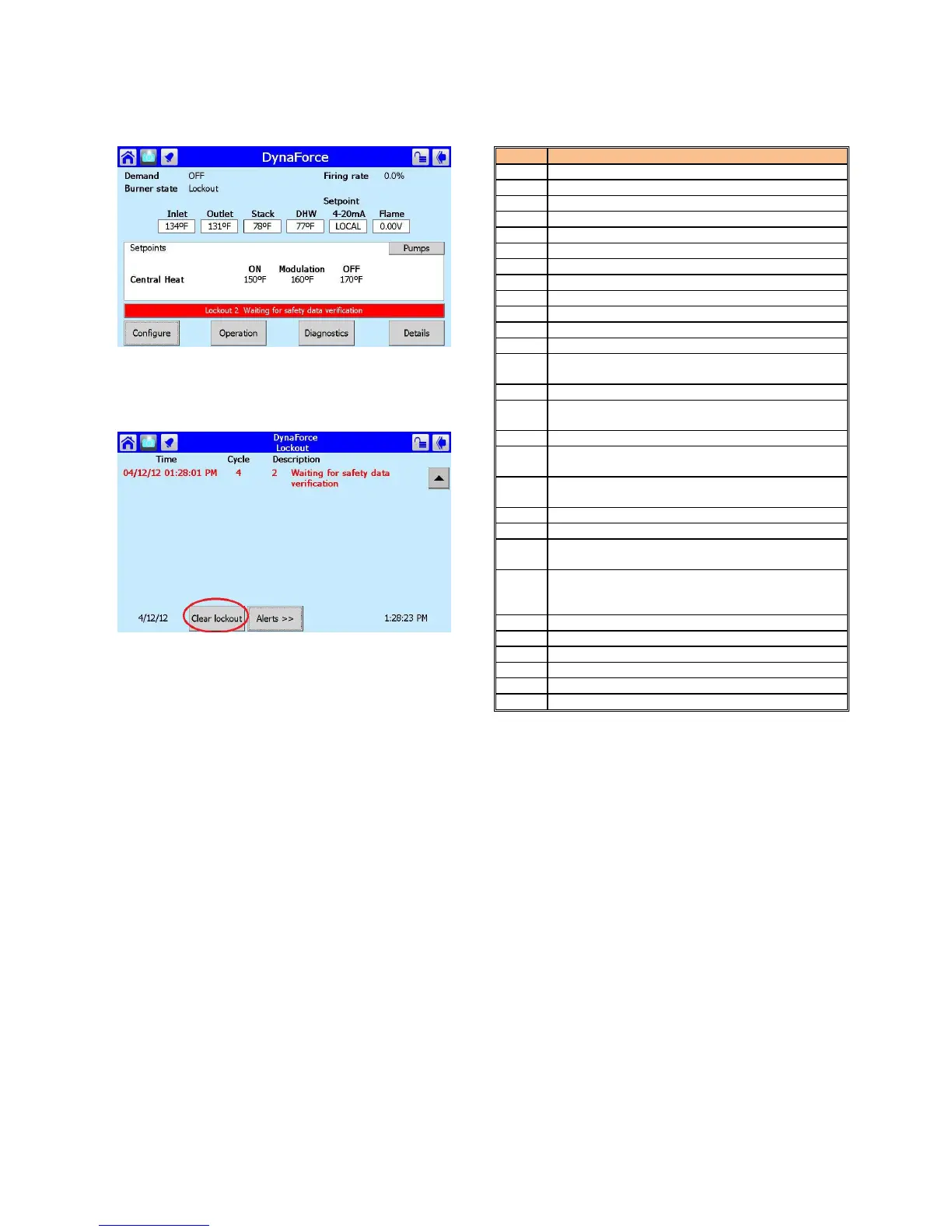

Figure 22: Lockout Condition

To eliminate the lockout error,

1) Press the red bar, indicating a Lockout condition

2) Press the [Lockouts] button

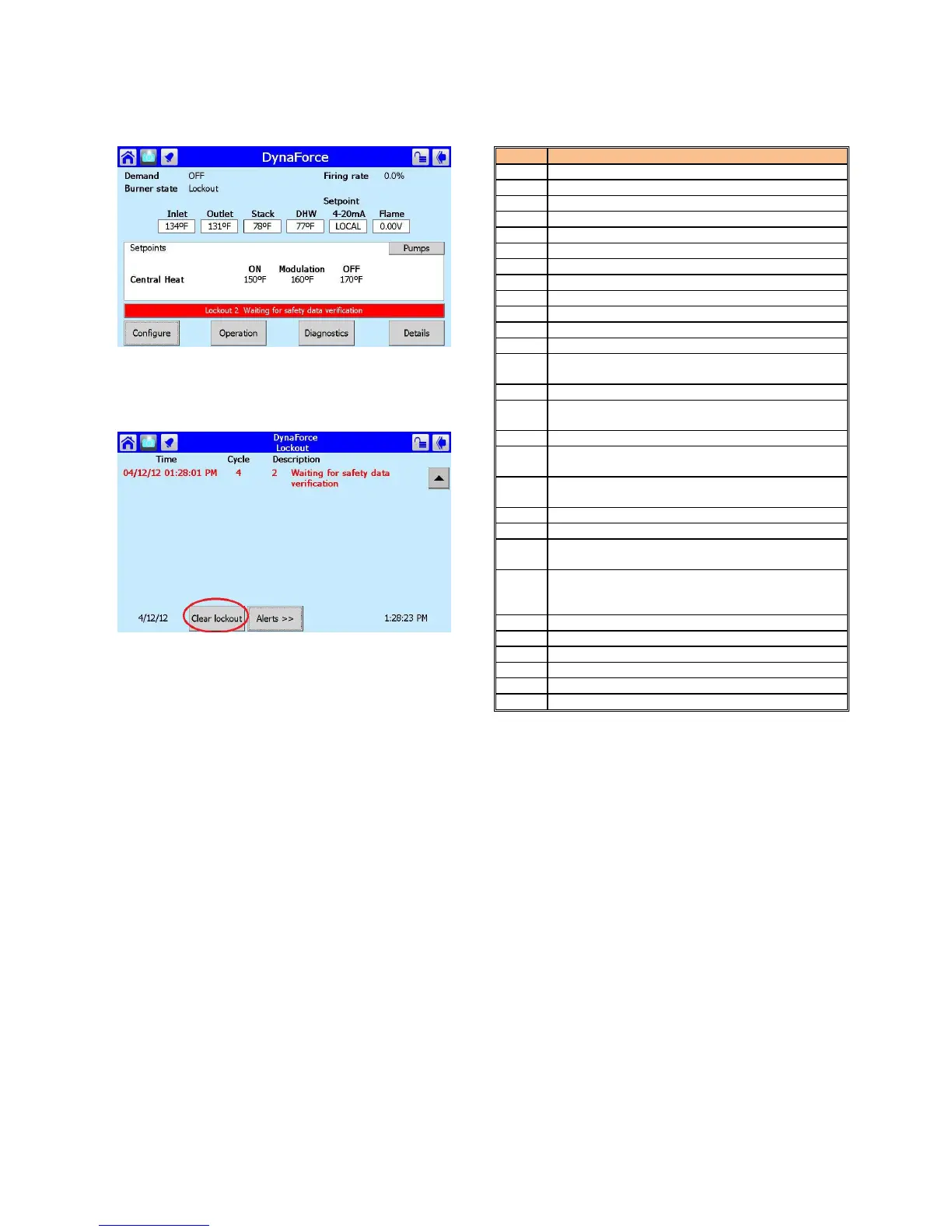

Figure 23: Lockout History

3) Press [Clear Lockout]

Table 13: Alert/Hold Codes

30 Burner switch turned ON

Invalid subsystem reset request occurred

50 Modulation Fault (DR300 – 1000 ONLY)

68 Setpoint was overridden due to sensor fault

69 Modulation was overridden due to sensor fault

123 Modulation rate was limited due to outlet limit

124 Modulation rate was limited due to Delta-T limit

No Lead Lag slaves available to service demand

219

Using backup Lead Lag header sensor due to

sensor failure

229 Lead lag slave communication timeout.

275-

LCI off, safety circuit is open

283 Demand off during measured purge time

291

Abnormal Recycle: Flame was not on at end of

Ignition period

292

Abnormal Recycle: Flame was lost during Main

293 Abnormal Recycle: Flame was lost early in Run

Abnormal Recycle: Flame was lost during Run

303-

310

+

Interlock Off, safety circuit is open

324,

374-

379

Hardware flame bias. Flame sensor wire needs to

be re-routed.

352

460 LCI lost in run

550 Delta T inlet/outlet limit was exceeded

* If an internal hardware fault is detected contact Camus®

technical support for troubleshooting procedure.

+

The alarm LED and alarm contacts are closed and will

remain closed until the ‘RESET’ button is pressed.

Loading...

Loading...