6.3 LEAD LAG SETUP UP TO 8 BOILERS

The following components are needed for a Lead Lag setup

1) 10k System Sensor

Turn off all the boilers before beginning the setup process.

To setup the Dynaforce® Lead Lag system follow the

instructions:

System Sensor

Insert the supplied 10k system sensor into the building loop.

The wires coming out of the system sensor should be

connected to Sys/Outdr terminals in the junction box.

NOTE

The use of a system sensor is required in lead lag operation.

1) When variable speed main circulators ARE NOT used

the system sensor is to be placed into the return

system piping.

2) When variable speed main circulators are used the

system sensor is to be placed into the supply system

piping.

All SOLA controllers are programmed with a default address of

1. The address of the slave controllers in the system must

have a unique address (1..8).

Sequence of Operation:

When a boiler is set as Lead Lag Master = Enabled and

Modbus address = 1, the controller of this boiler will drive the

lead lag operation.

The outdoor temperature sensor connected to the slave boiler

2 (ie. B-2) will be the outdoor sensor for the lead lag system

• The system temperature sensor connected to boiler 1

(the master) in terminals labeled “Outdr/Sys” in the

junction box will be the control sensor for lead lag

operation.

• The start/stop signal connected to boiler 1 (the

master) at terminals labeled “Remote Operator” will

be the heat demand input for lead lag operation.

When demand for heat is present the lead boiler will start and

uses the lead lag parameters for boiler modulation. After a

period of “Interstage delay” the master boiler compares the

lead lag temperature with the lead lag set point and will check

if:

1) An additional boiler is needed

Lead lag temp < Lead lag setpoint – Add stage Error

threshold

2) Number of boilers remain the same

Lead lag > Lead lag setpoint – Add stage Error

threshold AND

Lead lag temp < Lead lag setpoint + Drop stage Error

threshold

3) A boiler should stop

Lead lag temp > Lead lag setpoint + Drop stage Error

threshold

4) All boilers off

Lead lag temp > Lead lag setpoint + off hysteresis

If the lead lag master system is interrupted the remaining

boilers will operate as standalone boilers based on the Central

Heat or DHW parameters when set to “Enabled”.

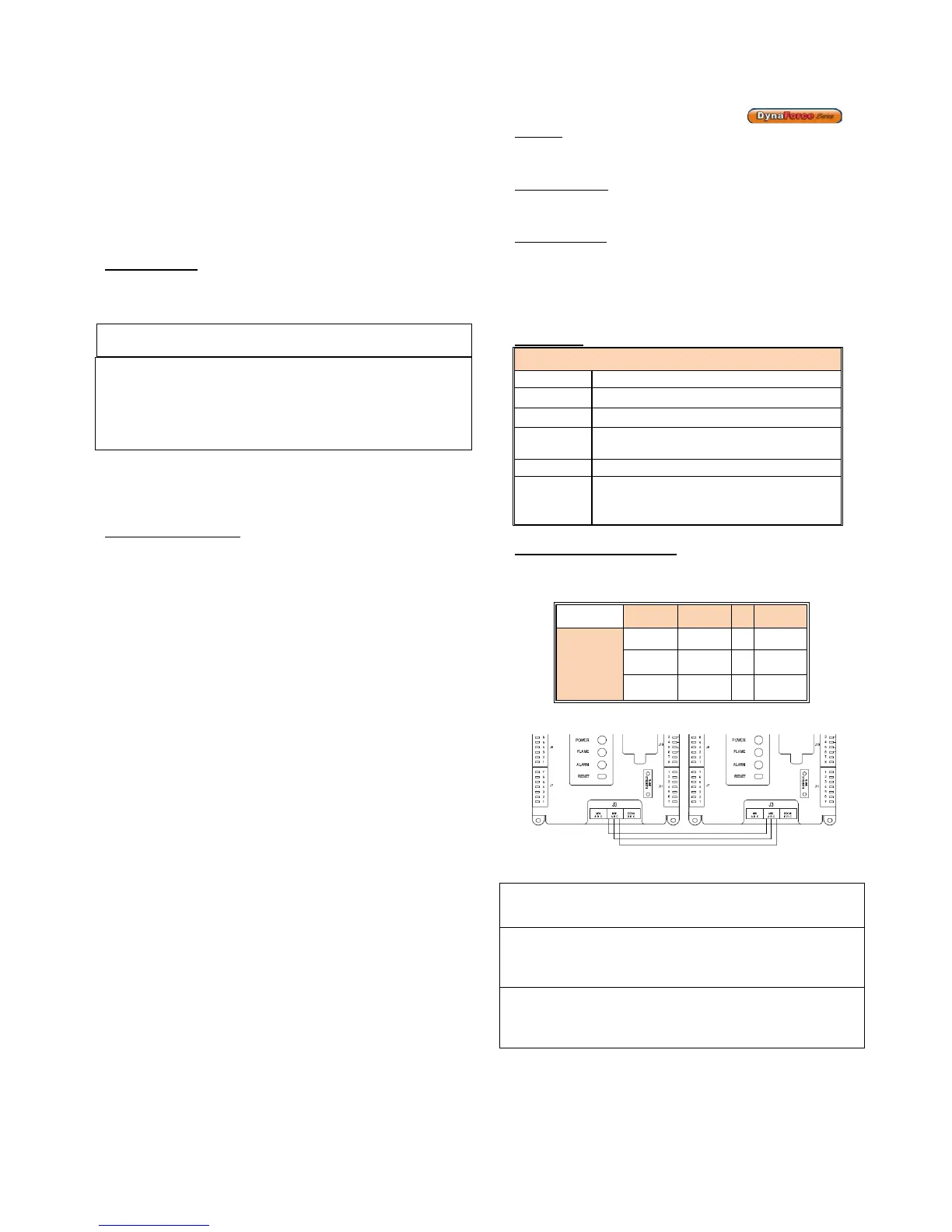

Rotation

Rotation time is configurable based on equalized run time

(default) or a fixed rotation schedule.

Interstage Delay

The length of time to wait between starting the next boiler

in sequence. (Default: 2 minutes)

Base Load Rate

When a call for heat is initiated the lead boiler runs up to

the desired base load rate (Default: 80%) and continues to

operate in this fashion based on the above 4 scenarios. If

the lead lag temperature is not satisfied a second boiler is

fired and they would both operate up to 80% fire rate.

Slave State

Slave Status Manager

Unknown Table entry is unused or empty

Available Slave is operational and ready to use

Add Stage Stage is getting ready to fire

Suspend

Stage

Stage was getting ready but is not needed

Loading...

Loading...