45

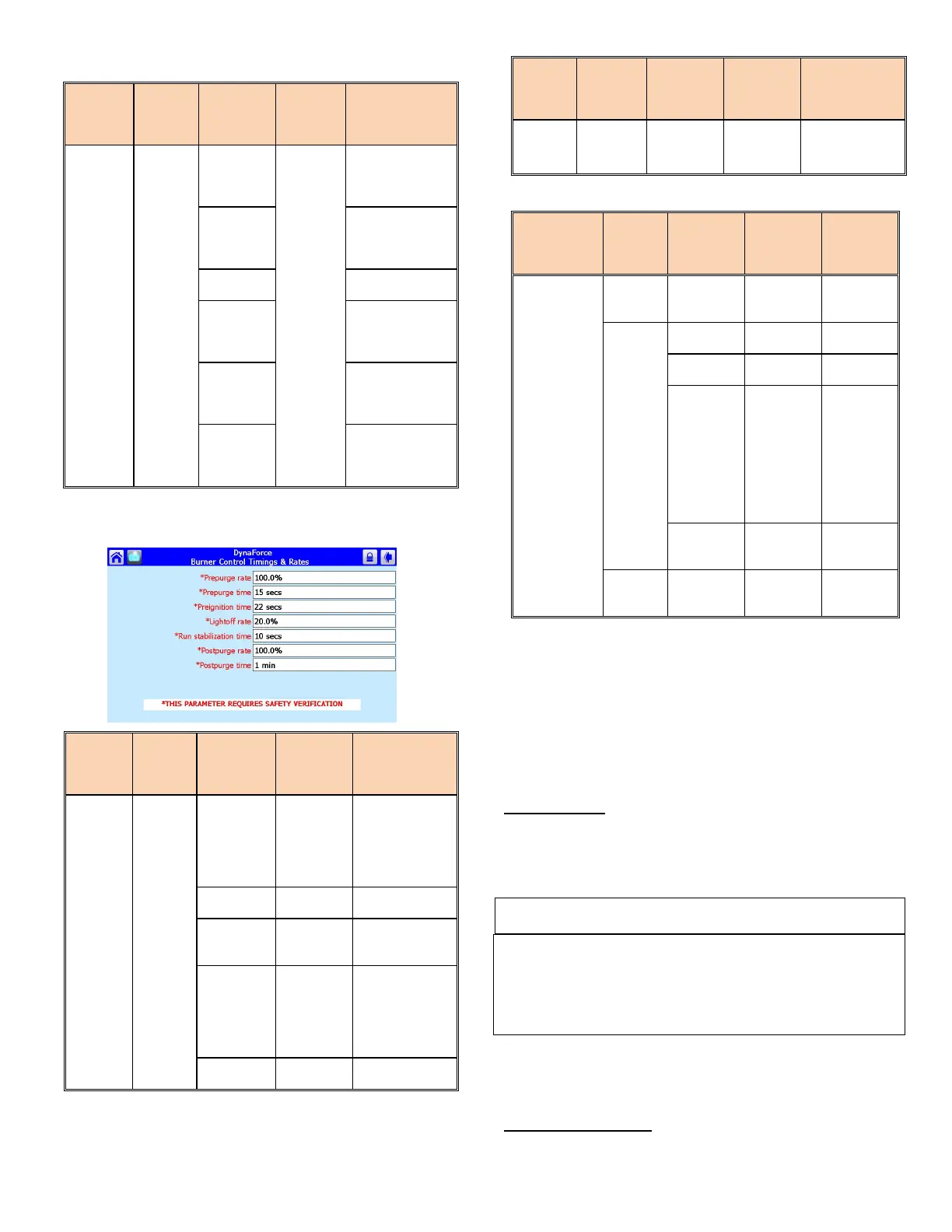

6.2.3 Statistics Configuration

Menu

Group

Selection

Menu

Group

Parameter Selection Description

Boiler

pump

cycles

number of cycles

the boiler pump

Burner

cycles

number of cycles

the burner has

Displays burner

run time in hours

CH pump

cycles

number of cycles

the CH pump has

DHW pump

cycles

number of cycles

the DHW pump

System

pump

cycles

number of cycles

the system pump

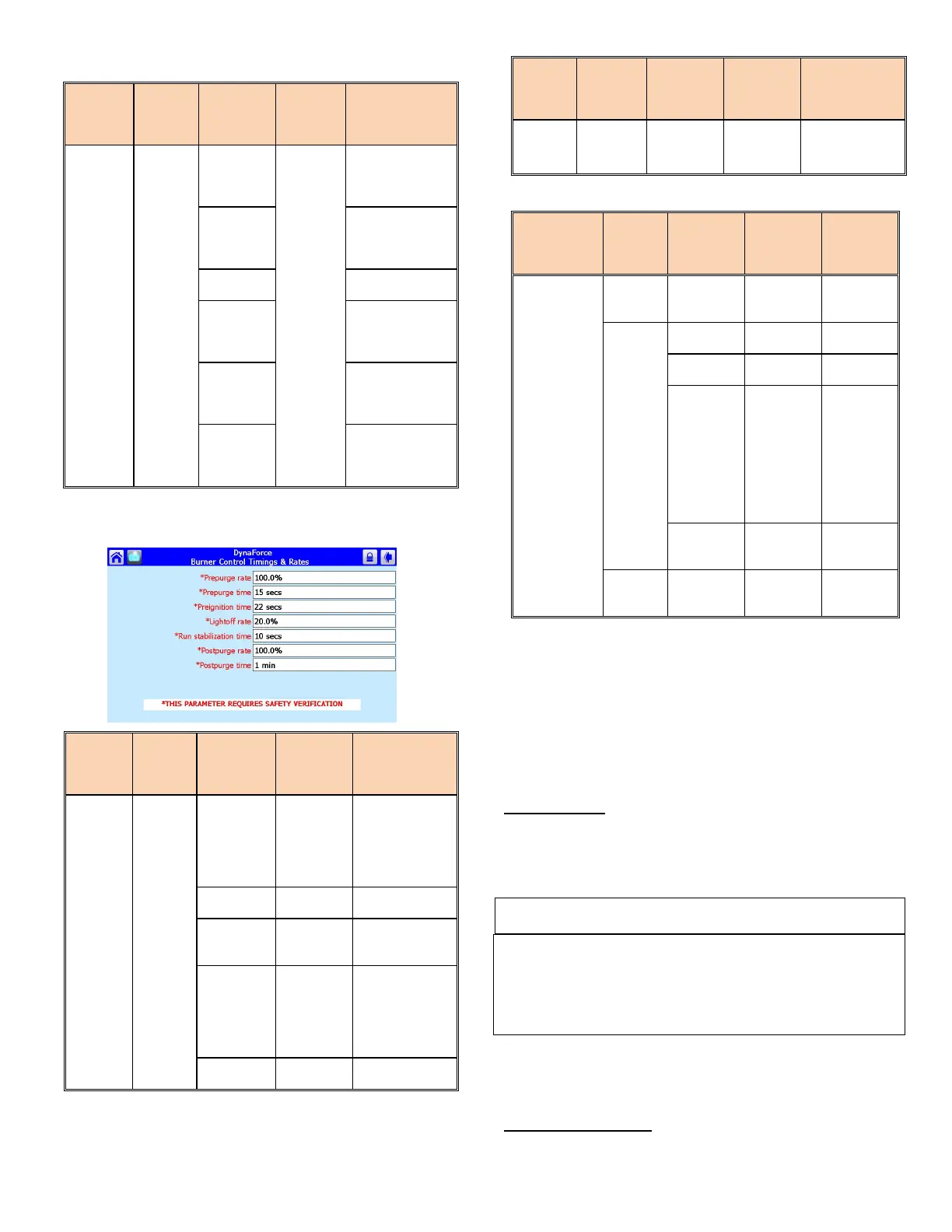

6.2.4 Burner Control Timing and Rates

Figure 27: Burner Control Timing and Rates

Menu

Group

Selection

Menu

Group

Parameter Selection Description

Burner Control Timing and Rates

Prepurge

rate

3000 RPM

speed (Default:

DR300 – 1000:

3000 RPM,

DR1200 – 5000:

Prepurge time

(Default: 25 sec)

Stabilization

10 sec

establishing

Postpurge

rate

3000 RPM

speed (Default:

DR300 – 1000:

3000 RPM,

DR1200 – 5000:

Postpurge time

(Default 25 sec)

6.2.5 Burner Control Ignition

Menu

Group

Selection

Menu

Group

Parameter Selection Description

Lightoff

rate

3000 RPM

DR1200 –

speed

6.2.6 Sensor Configuration

Menu Group

Selection

Menu

Group

Parameter Selection Description

Sensor

Configurations

S1 (J8-4)

sensor

single non-

Inlet Sensor

4-20mA

S5 (J8-11)

sensor

10K NTC

single non-

safety

Sensor:

Standalone

boiler or

Slave boiler

Header

sensor:

Master

S6S7 (J9-

1,3) sensor

single non-

Sensor

S8S9 (J9-

4,6) sensor

single non-

Stack

Sensor

6.3 LEAD LAG SETUP UP TO 8 BOILERS

The following components are needed for a Lead Lag setup

1) 10kΩ System Sensor

Turn off all the boilers before beginning the setup process.

To setup the Dynaforce® Lead Lag system follow the

instructions:

System Sensor

Insert the supplied 10kΩ system sensor into the building loop.

The wires coming out of the system sensor should be connected

to Sys/Outdr terminals in the junction box.

NOTE

The use of a system sensor is required in lead lag operation.

1) When variable speed main circulators ARE NOT used

the system sensor is to be placed into the return

system piping.

2) When variable speed main circulators are used the

system sensor is to be placed into the supply system

piping.

All SOLA controllers are programmed with a default address of

1. The address of the slave controllers in the system must

have a unique address (1..8).

Sequence of Operation:

Loading...

Loading...