53

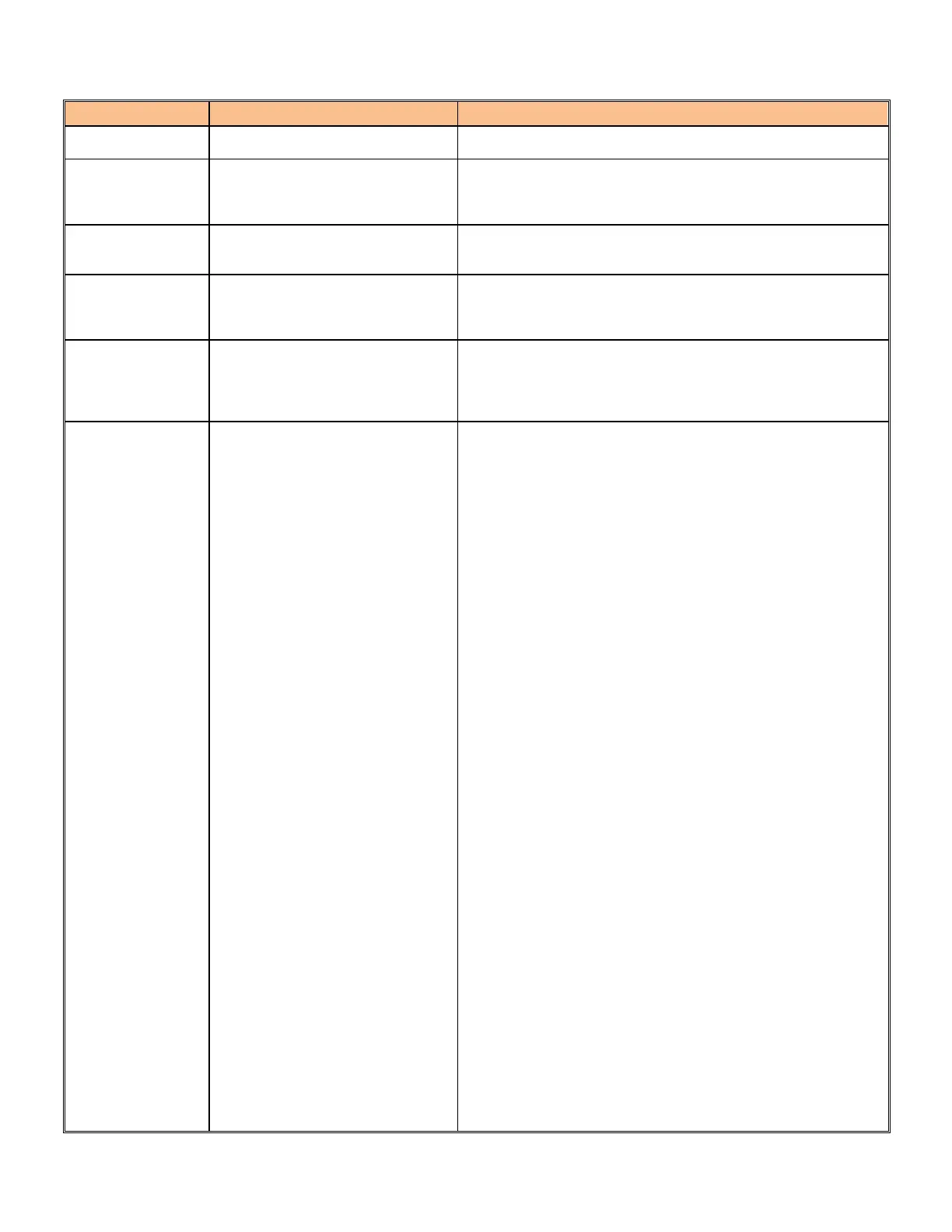

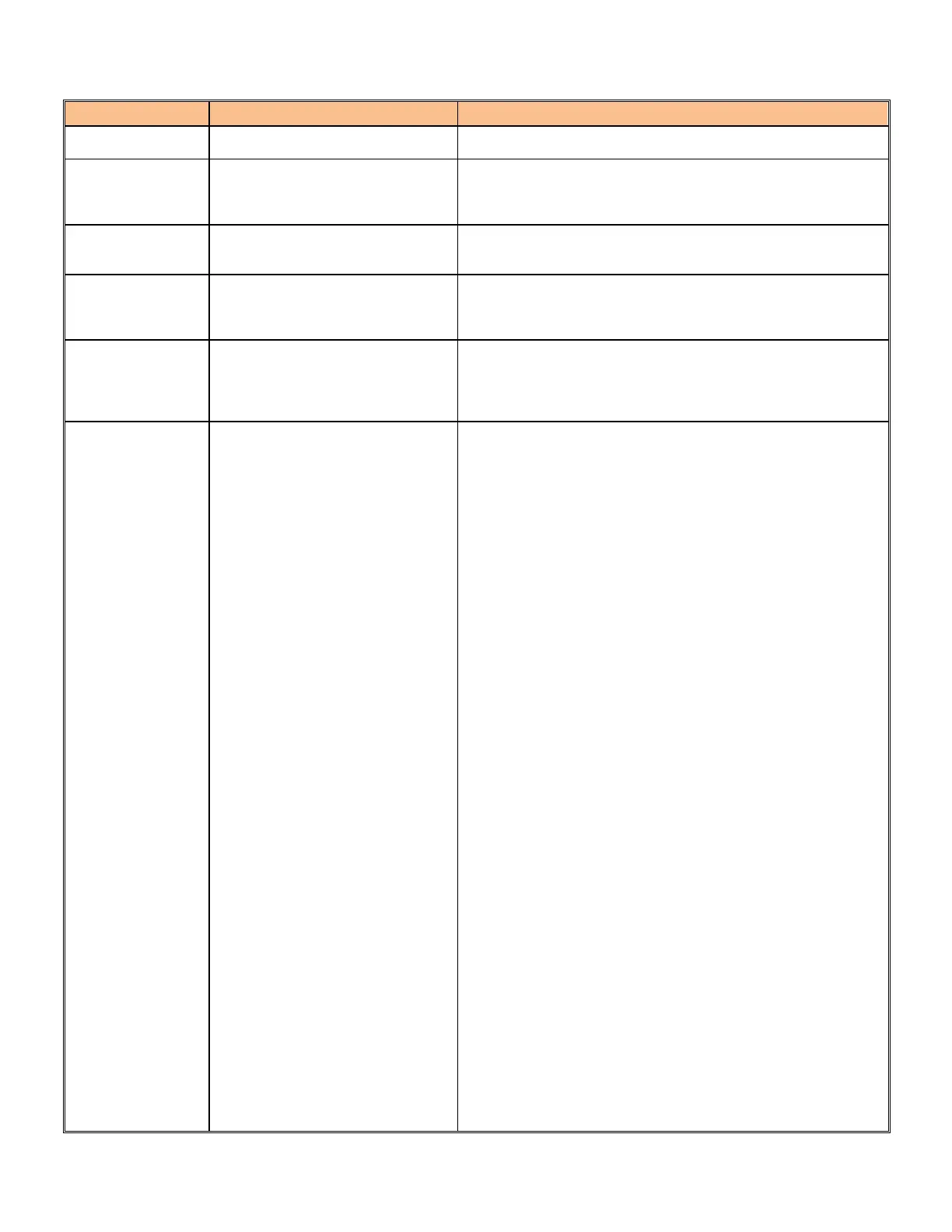

PART 9 TROUBLESHOOTING

Incoming Power

• No effect on safety

• Live and Neutral wires are interchanged.

Transformer

Tripped

• The 24Volts and 120 Volts wired

are interchanged

• Alert: 49

• Breaker on transformer trips

Relief Valve

• System pressure exceeds relief

valve setting

• Replace the standard relief valve with a higher rated valve up to

the maximum pressure of the heat exchanger.

• Improperly sized expansion tank.

Flow Switch

• Flow Switch contacts are open

• Alert: 63, 275-281, 460

• LCI OFF

• Verify that pump is operating

• Verify for closed valves or obstructions in boiler piping

• Verify that all air has been purged from the system

• Verify that wiring is correct

Water Pressure

Switch

• Pressure Switch contacts are open

• Alert: 63, 275-281, 460

• LCI OFF

• Verify that minimum water pressure exceeds 30 PSI

• Verify that pump is operating

• Verify for closed valves or obstructions in boiler piping

• Verify that all air has been purged from the system

• Verify that wiring is correct

Flame Failure

• The boiler has failed to ignite the

burner

• Alert: 110, 291-294

• To reset the module refer to section 5.8.2

• Verify that all air has been purged from gas line

• Inspect hot surface igniter and related wiring for damage and

connection errors

• DR 300 – 2500: Verify igniter is glowing

• DR 3000 – 5000: Verify pilot is lit

• Inspect flame sensor and associated wiring. Replace if

necessary

• Verify that boiler is properly grounded

• Verify incoming gas supply pressure and that it coincides with

Table 7.

• Verify that the vent/ air inlet piping (if equipped) are correctly

installed and obstructions are not present.

• Verify 24 VAC (DR 300 – 1200) and 115VAC (DR 1400 – 5000)

is being supplied to the gas valve relay from the Dynaforce®

Controller during ignition. Check wiring from Dynaforce®

Controller and Gas Valve Relay. If a signal cannot be detected,

the Dynaforce® Controller needs to be replaced

• If 24 VAC is present, check the outlet of the valve to ensure that

gas is flowing. When the valve is energized a change in

pressure should occur, if no change is detected the gas valve

has failed to open or it is passing insufficient amount of gas. If

this is an initial startup increase the low fire gas setting by ¼

turn clockwise.

• Inspect the burner. Refer to Burner Maintenance in section 10.5

• Replace the Dynaforce® Controller, if necessary

Loading...

Loading...