54

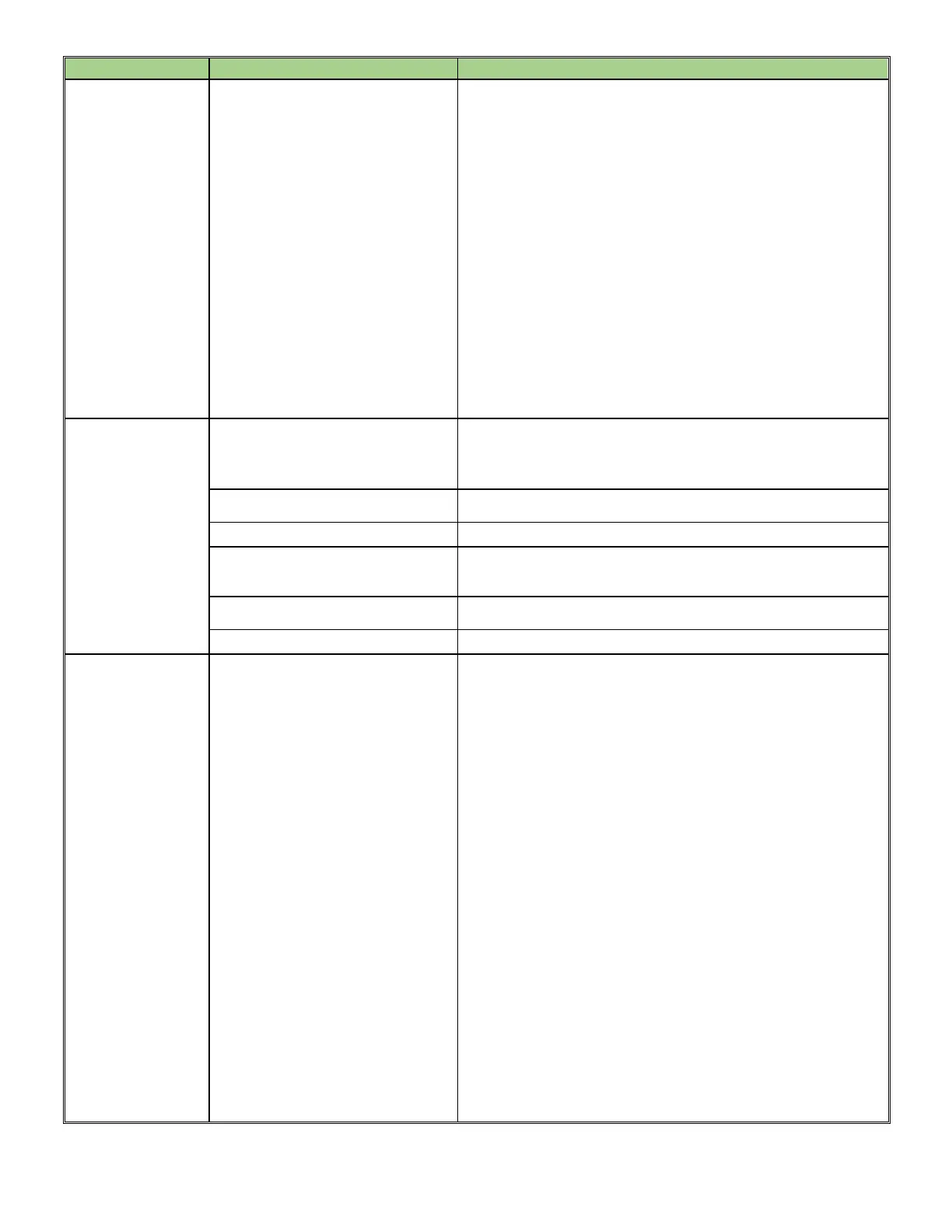

Flame Disappears

During a Run

Cycle

• The Dynaforce® boiler was

running and flame signal suddenly

disappeared.

• Lockout: 106, 107, 108, 109

• Verify that all air has been purged from gas line

• Verify that boiler is properly grounded

• Inspect flame sensor and associated wiring. Replace if

necessary

• Check for flame sensor cracks in the insulator or continuity to

ground

• Adjust the air proving switch. Turn counter-clockwise to reduce

sensitivity

• Adjust the blocked flue switch. Turn clockwise to reduce

sensitivity

• Verify incoming gas supply pressure and that it coincides with

Table 7.

• Verify that the gas line connections to the boiler are adequate.

Refer to Table 6.

• Verify that the vent/ air inlet piping (if equipped) are correctly

installed and obstructions are not present

• Verify that 24 VAC is being supplied to the gas valve during

operation. If a signal cannot be detected, the transformer needs

to be replaced

• Inspect the burner. Refer to Burner Maintenance in section 10.5

• Replace the Dynaforce® Controller if necessary

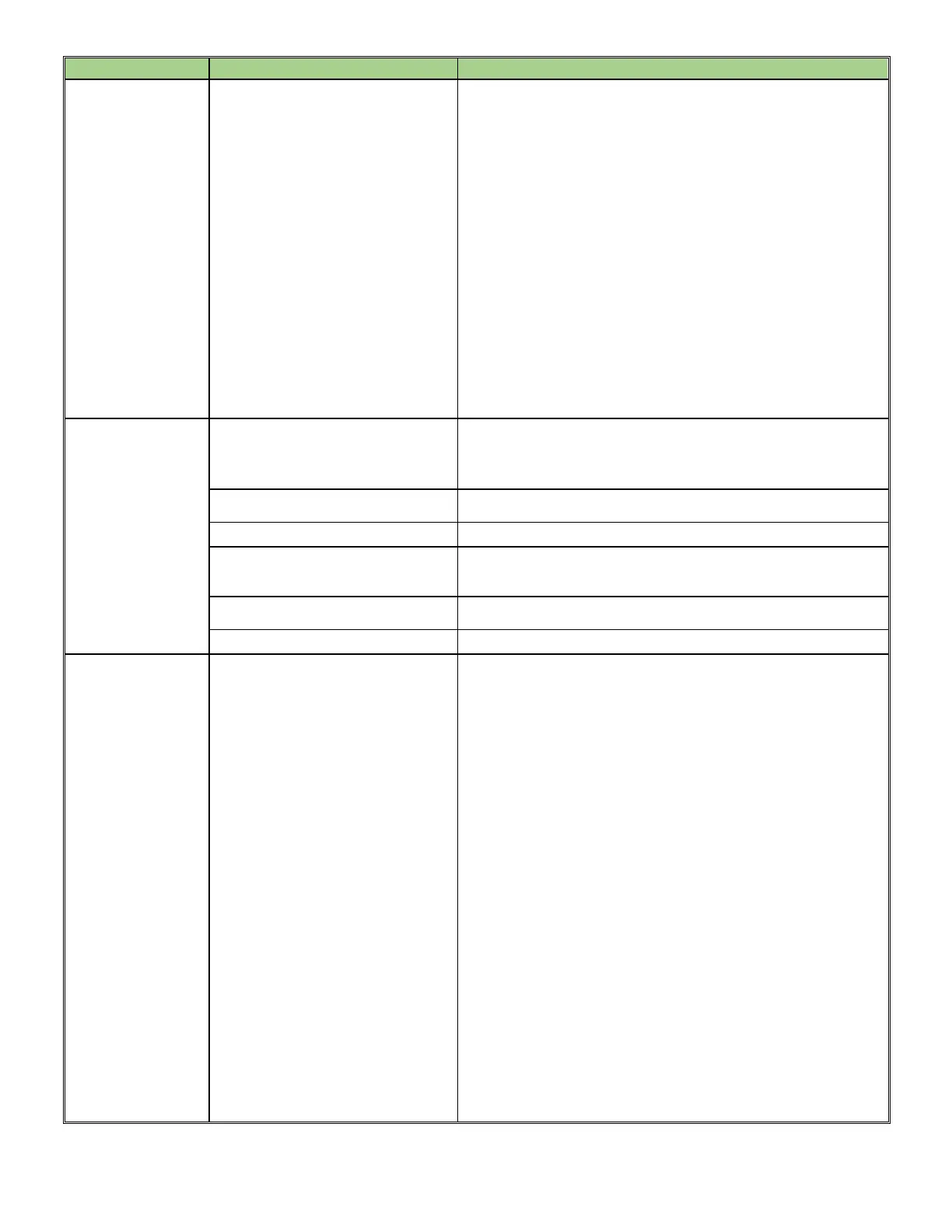

Noisy Operation

• Refer to Part 3 Gas Connection in this manual.

• Natural Gas Pressure reads between 3” w.c. and 14” w.c.

• L.P. Gas Pressure should be at 11” w.c.

• Refer to Section 8.3 Gas Valve Adjustment Procedure for proper

combustion setting.

• Air Inlet and/or Vent configuration

• Refer to Part 2 Air Inlet and Venting

• Refer to Burner Maintenance in section 10.5 of this manual for

the burner removal and inspection procedure. Clean or replace

• Check that all fan bolts are torqued to 20 lb-ft (DR300 – 1000),

25 lb-ft (DR1200 – 5000)

• Air in the piping system

• Purge all air from the piping system

Auto Reset High

Limit Trips

• The outlet temperature has

exceeded the set point

temperature specified.

• Alert: 67, 79, 137, 303-310

• ILK OFF

• Verify that the system is full of water and that all air has been

properly purged from the system.

• Verify that ∆T does not exceed 30

o

F across the heat exchanger

• Verify that the boiler is piped properly.

• Verify that 120VAC is being supplied to the boiler pump on a call

for heat. If voltage cannot be detected check wiring.

• Verify that the pump is circulating when 120VAC is detected. If

not, pump impeller may be stuck. Use a flat head screwdriver on

face of pump to turn impeller manually

• If 120VAC is present during a call for heat, but the pump still

does not circulate, replace the pump.

• Replace the main Dynaforce® Controller if necessary

Loading...

Loading...