BUILT-IN GAS OVENS WITH GRILL ▪ FO Series

19

FO Series – ed. 01/2020

CONNECTION TUBE REQUIREMENTS

CAUTION!

The connection of the equipment to the gas pipeline shall be carried out by means of

a suitable connection pipe with the use of certified sealing fittings of the most suitable

type for the application.

Flexible connection pipes can be used. They shall:

• always be easy to inspect,

• be protected against contact with hot parts (e.g. burner cups)

• be protected from the mobile parts of the recessed structure (drawers, doors, etc...),

• have length in accordance with the technical standards for each sector of reference.

Avoid any kind of mechanical stress on the hoses during installation and during use (protection

against pulling, twisting, crushing, etc.).

CAUTION!

Perform maintenance and periodic replacement of the hose by the expiry date stated

on the sheath. Never use expired or damaged hoses.

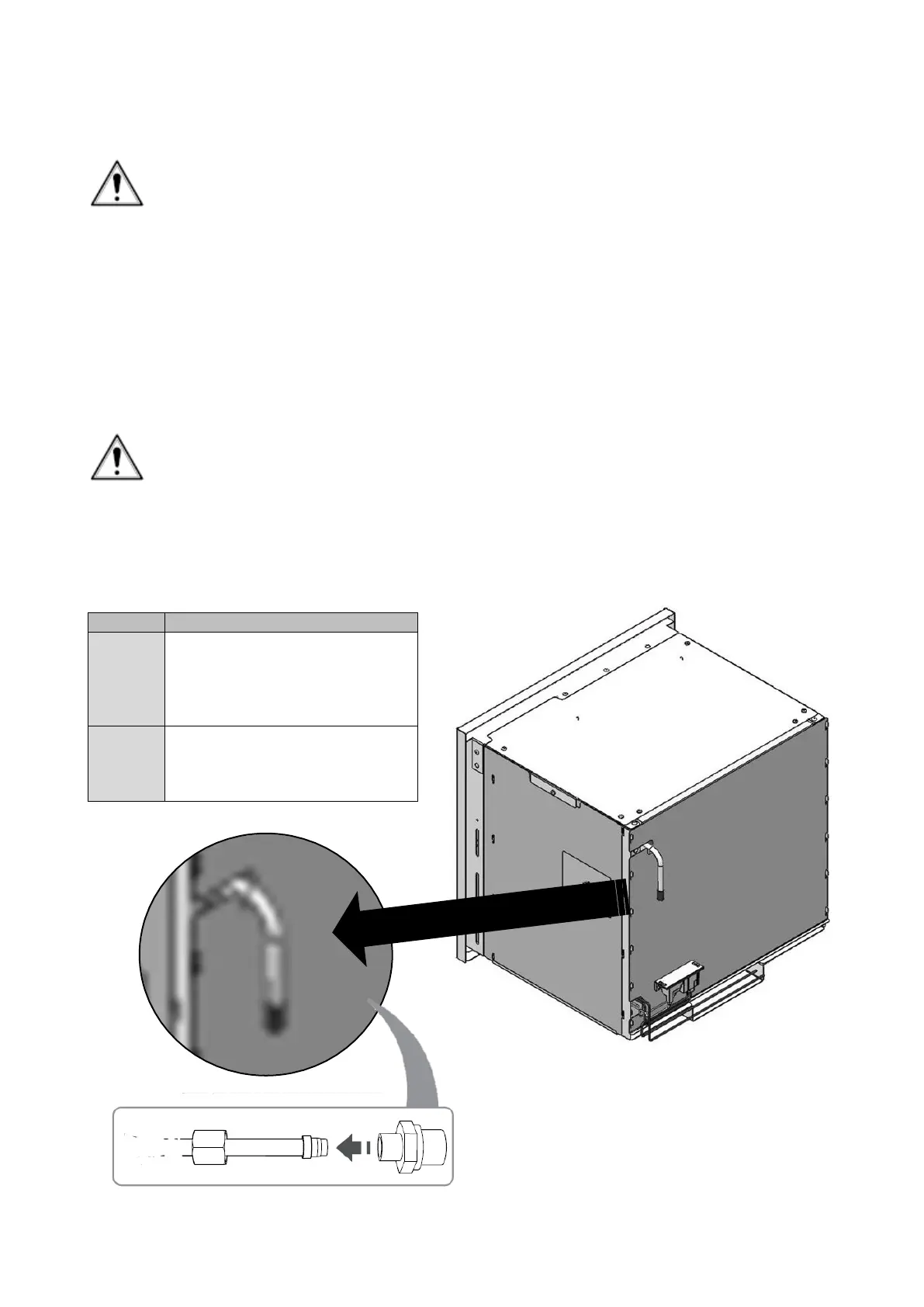

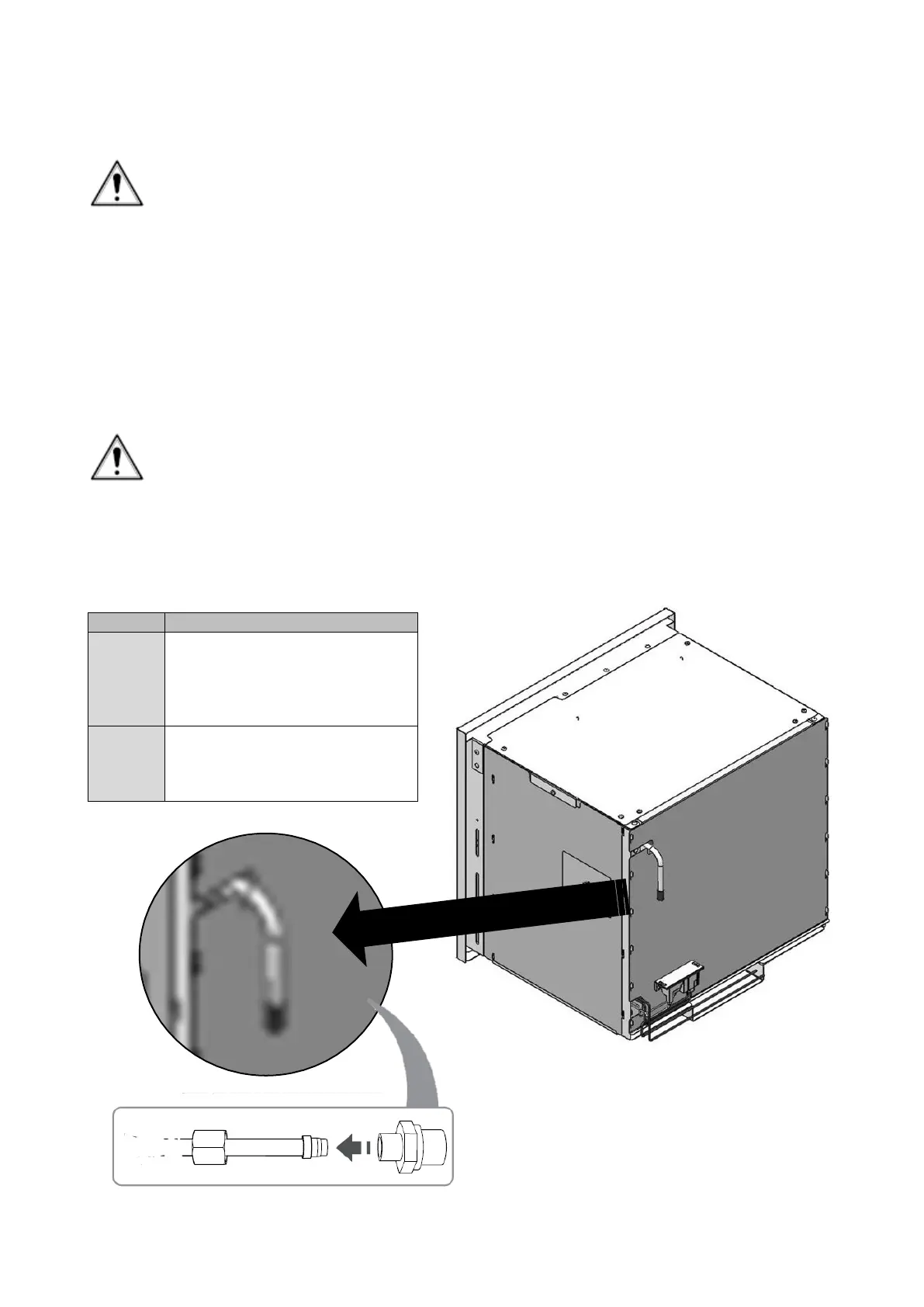

GAS CONNECTION PROCEDURE

The equipment is supplied with a gas ramp having a smooth and free terminal section of at least 30

mm, suitable for housing adequate compression fittings. The gas connection terminal is located on

the back of the product. To perform the gas connection, follow these steps:

Important:

fittings are not part of the product.

The supply and connection are

to be provided solely by the installer.

Loading...

Loading...