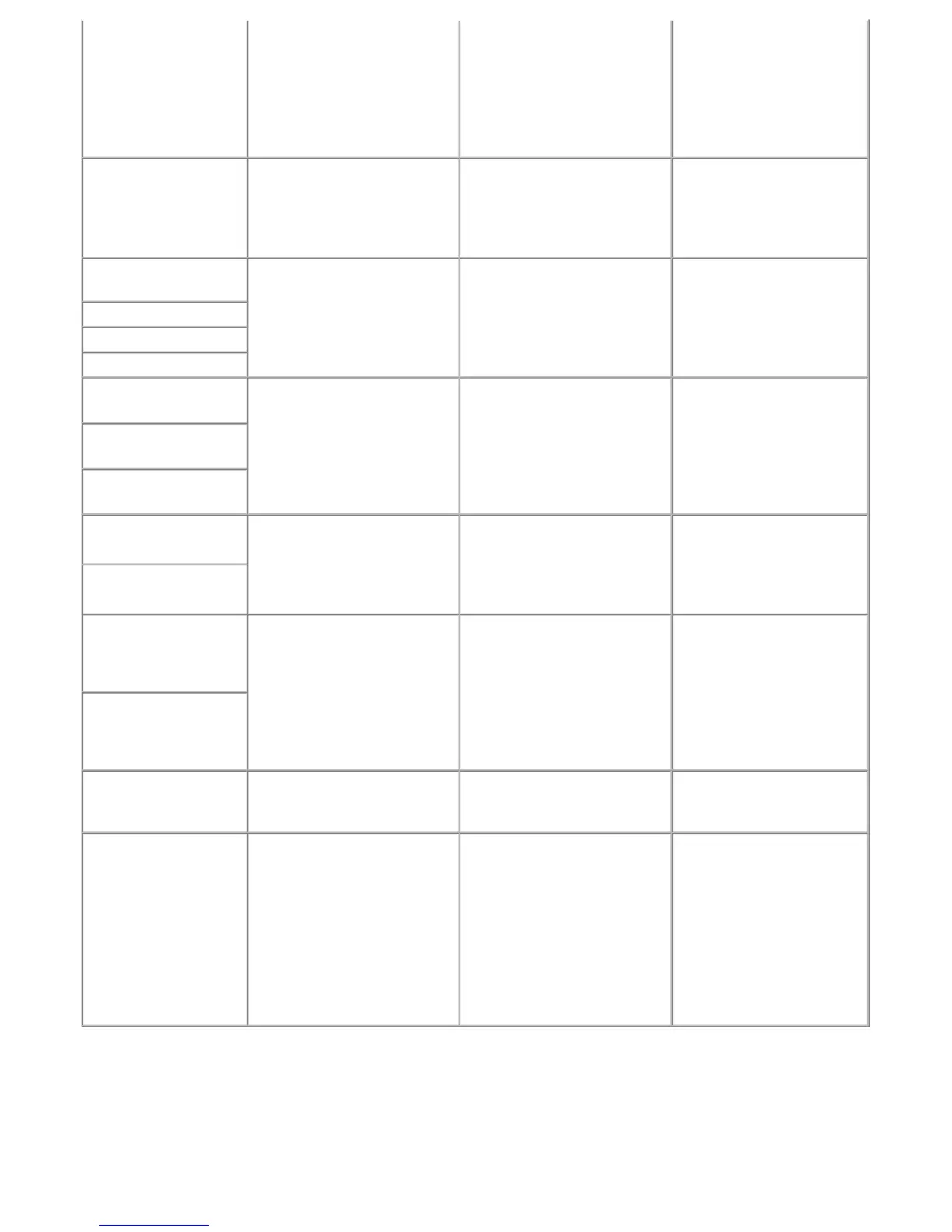

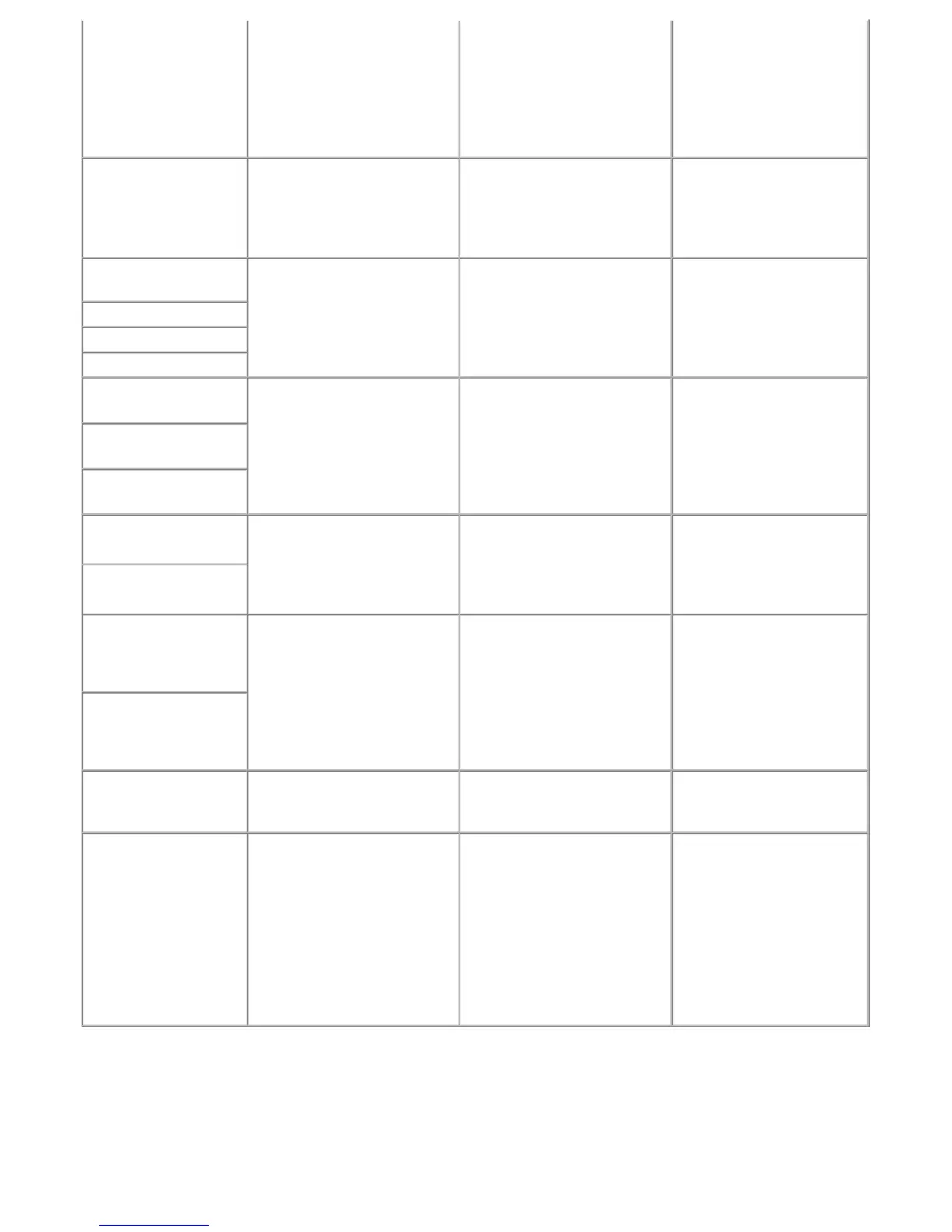

Spur unit - DO NOT contact the spur edges.

After replacement:

1. Check the ink system function.

2. Perform LF / Eject correction in

the service mode.

[See 3-3. Adjustment /

Settings, (6) Service mode, for

details.]

- EEPROM information print

- Service test print

Purge drive system unit

After replacement:

1. Confirm the purging operation

and the machine operation.

[See 3-4. Verification After

Repair for details.]

- Service test print

Carriage rail and main

chassis

At replacement:

1. Apply grease to the sliding

portions.

[See 3-3. Adjustment /

Settings, (3) Grease

application, for details.]

- Service test print

Idler pulley parallel pin

Easy-Scroll Wheel base

APP code wheel gear shaft

Document pressure sheet

After replacement:

1. Confirm the document pressure

sheet position.

[See 3-3. Adjustment /

Settings, (2) Document

pressure sheet replacement, for

details.]

- Service test print

Document bottom cover

Scanner unit

Panel board ass'y - Be cautious not to scratch or

damage the LCD cable.

At replacement:

1. Perform button and LCD test.

[See 3-3. Adjustment /

Settings, (6) Service mode, for

details.]

- Service test print

LCD viewer unit

Timing slit strip film - Upon contact with the film, wipe

the film with ethanol.

- Confirm no grease is on the film.

(Wipe off any grease thoroughly

with ethanol.)

- Do not bend the film

After replacement:

1. Perform print head alignment in

the user mode.

2. Perform LF / Eject correction in

the service mode.

[See 3-3. Adjustment /

Settings, (6) Service mode, for

details.]

- EEPROM information print

- Service test print

Timing slit disk feed film

Print head

After replacement:

1. Perform print head alignment in

the user mode.

- Service test print

Wireless LAN board ass'y

After replacement:

1. Reset the LAN settings in the

user mode.

2. Print the EEPROM information

to confirm that the WL LAN

MAC address is properly

updated.

[See 3-3. Adjustment /

Settings, (6) Service mode, for

details.]

- EEPROM information print

- Service test print

Loading...

Loading...