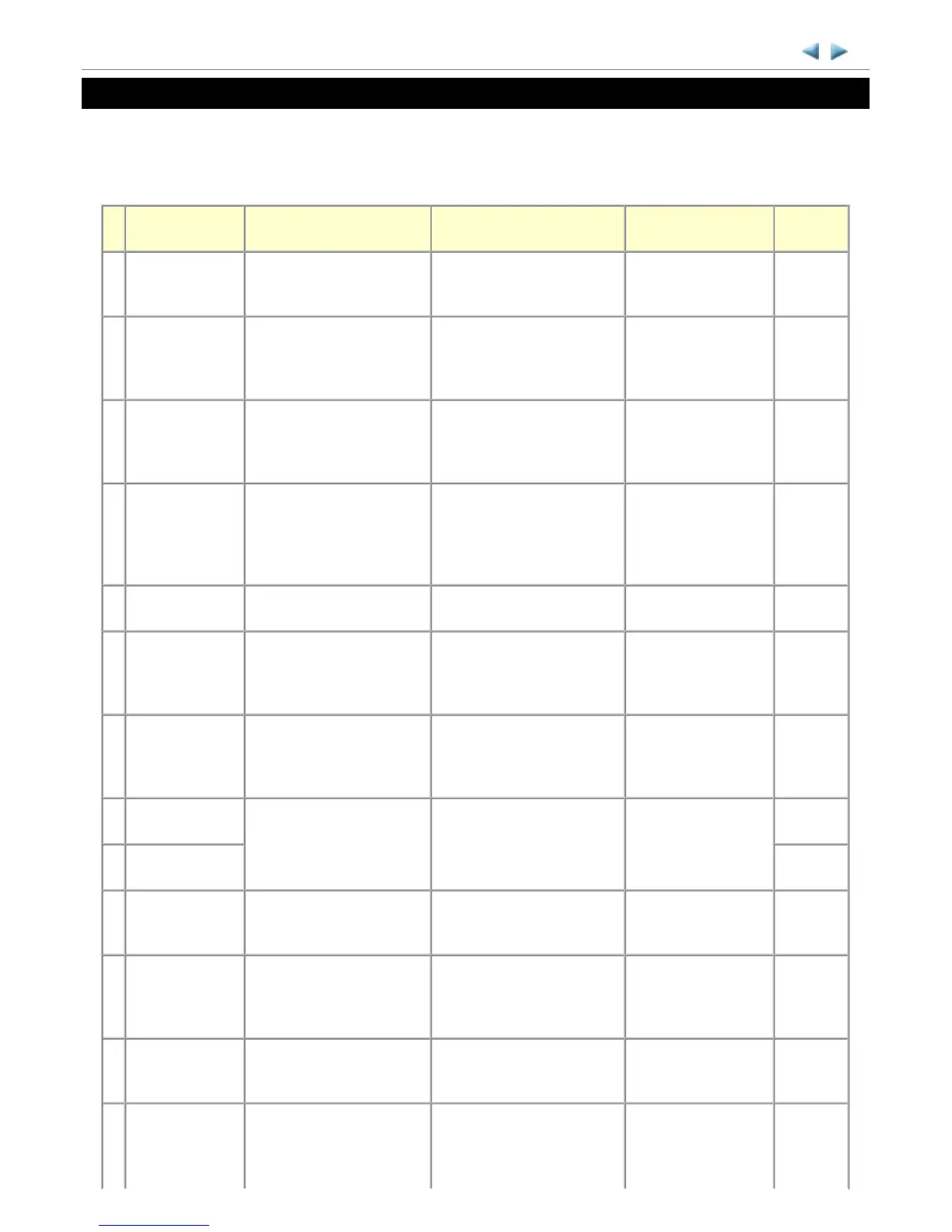

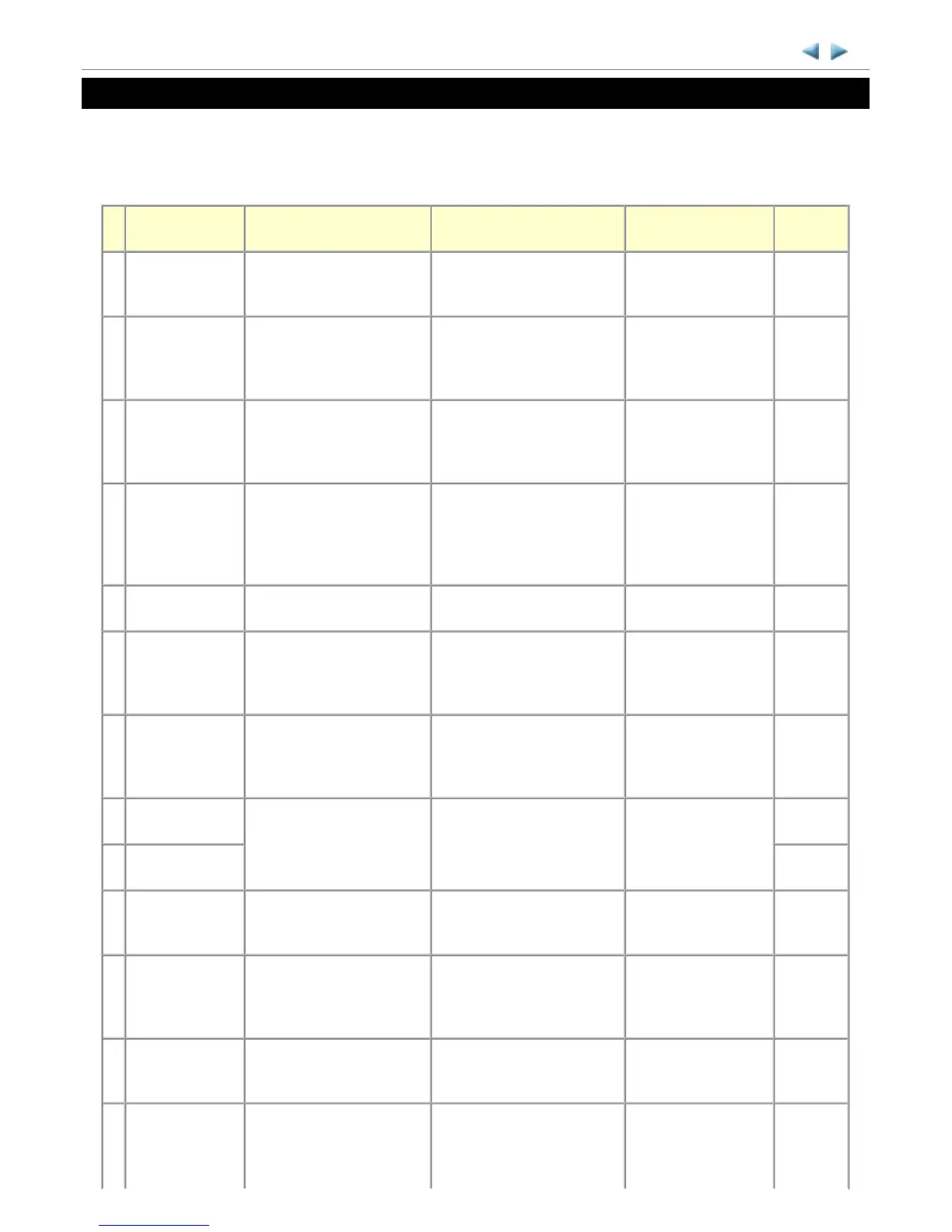

1. MAINTENANCE

1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement Consumables

by Service Engineer

(1) Adjustment

MP640 / MP648 TABLE OF CONTENTS

Adjustment Timing Purpose Tool

Approx.

time

EEPROM

initialization

- At logic board replacement To initialize settings

Service Tool

*2

Perform in the service

mode.

1 min.

Destination

settings

(EEPROM

settings)

- At logic board replacement To set destination.

Service Tool

*2

Perform in the service

mode.

1 min.

Ink absorber

counter resetting

(EEPROM

settings)

- At logic board replacement

- At ink absorber replacement

To reset the ink absorber

counter.

Service Tool

*2

Perform in the service

mode.

1 min.

Ink absorber

counter value

setting

(EEPROM

settings)

- At logic board replacement To set the ink amount data in

the ink absorber to the ink

absorber counter.

Service Tool

*2

Perform in the service

mode.

1 min.

Ink absorber

replacement

- When the ink absorber

becomes full

To replace the ink absorber

with a new one.

Screwdriver, a pair of

tweezers, etc.

15 min.

Paper feed motor

position

adjustment

- At paper feed motor

replacement

To adjust the belt tension.

(Position the paper feed motor

so that the belt is stretched

tight.)

None. 5 min.

CD / DVD

detection sensor

light volume

correction

*1

- At carriage unit replacement

- At logic board replacement

To correct the light volume for

the CD / DVD detection

sensor.

Service Tool

*2

Perform in the service

mode.

5 min.

Automatic print

head alignment

- At print head replacement

- At logic board replacement

- When print quality is not

satisfying

To secure the dot placement

accuracy.

None.

Perform in the user

mode.

5 min.

Manual print head

alignment

10 min.

Grease application - At carriage unit replacement

- At Easy-Scroll Wheel

replacement

To maintain sliding properties

of the carriage rail.

FLOIL KG-107A 1 min.

Ink system

function check

- At logic board replacement

- At spur unit replacement

- At carriage unit replacement

To maintain detection

functionality for presence of

the ink tanks and each ink tank

position.

Service Tool

*2

Perform in the service

mode.

1 min.

LCD language

settings

- At logic board replacement To set the language to be

displayed on the LCD.

None.

Perform in the user

mode.

1 min.

Platen glass

protection sheet

(document

pressure sheet)

- At protection sheet

replacement

- At document bottom cover

replacement

To maintain scanning

accuracy, hold the sheet with

the long side down, then fit its

upper left corner to the platen

None. 1 min.

Loading...

Loading...