Standard air-conditioning units

Carel Cod. +030221421 – Rel. 1.2 – April, 11, 2003

19

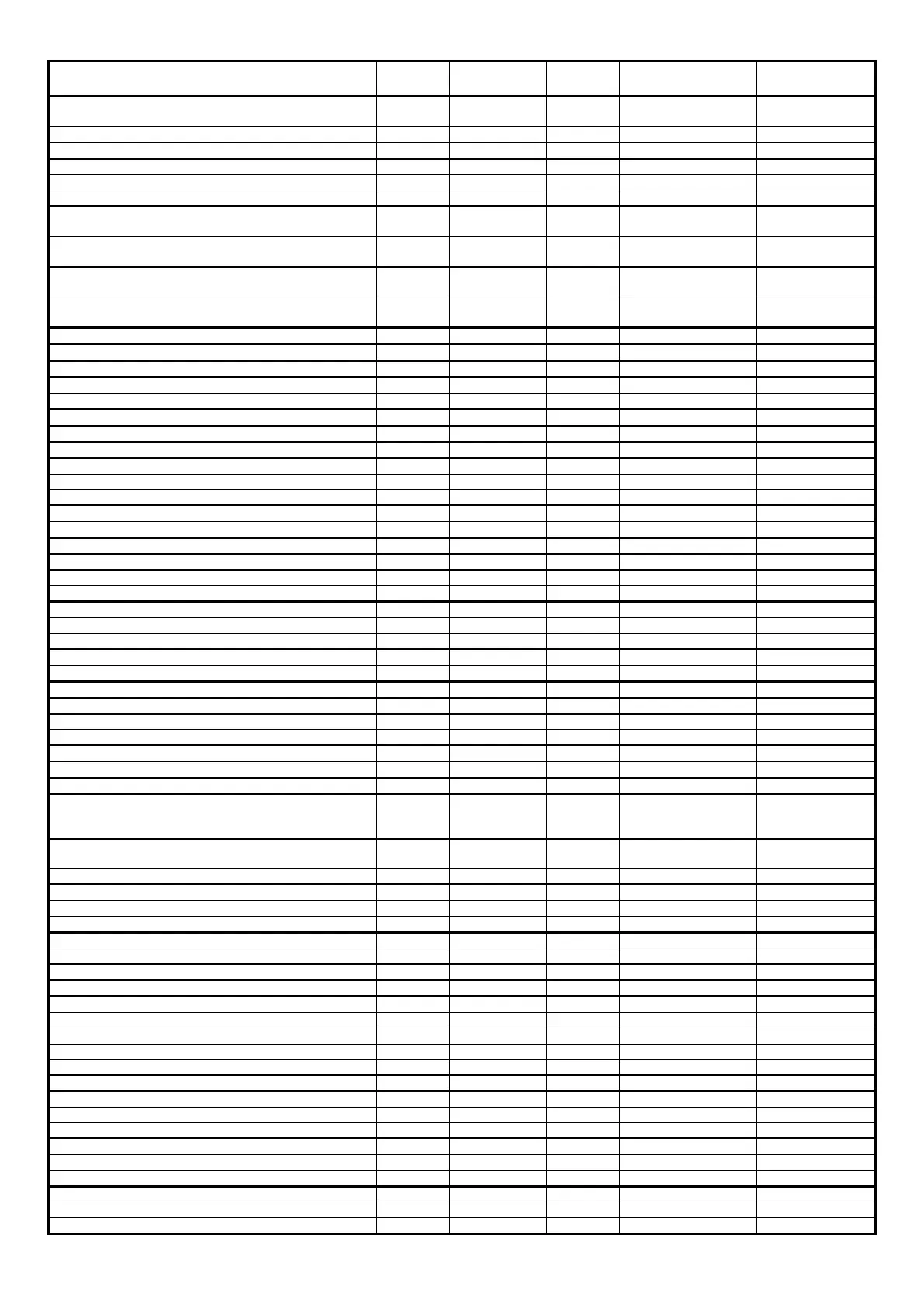

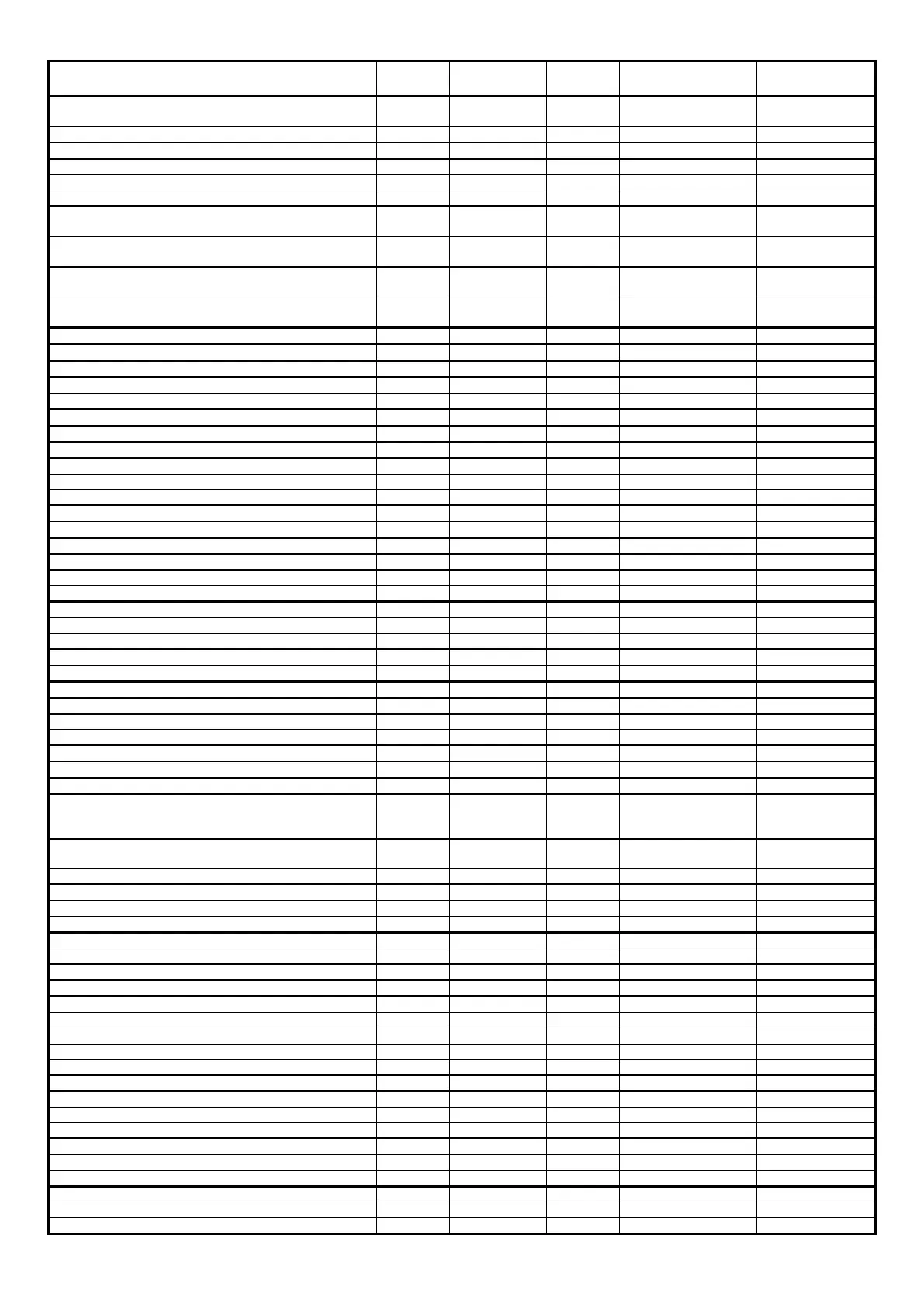

PARAMETER DESCRIPTION SCREEN DEFAULT USER

VALUE

RANGE UOM

pLAN connection class, boards 7 – 8 Cp

Not present

Present-rot., Present-no

rot., Not present

PARAMETERS →

Enable compressors/cooling coil together with recovery coil G0 No No-Yes

Enable FIFO compressor rotation G1 No No-Yes

Type of temperature control G1 Proportional Prop.-P+I

Logic of the capacity-control contact G1 NC NC-NO

Starting point to open modulating valve in cooling (or single

valve) with recovery (see G0)

G2 50.0 0.0-100.0 %

Starting and end point to open modulating valve in cooling (or

single valve)

G2 0.0 / 100.0 0.0-100.0 %

Starting point to open 3 position valve in cooling (or single

valve) with recovery (see G0)

G3 50,0 0.0-100.0 %

Starting and end point to open 3 position valve in cooling (or

single valve)

G3 0.0 / 100.0 0.0-100.0 %

Starting and end point to open modulating valve in heating G4 0.0 / 100.0 0.0-100.0 %

Starting and end point to open 3 position valve in heating G5 0.0 / 100.0 0.0-100.0 %

Starting and end point to open modulating valve in recovery G6 0.0 / 100.0 0.0-100.0 %

Minimum and maximum modulating fan speed G7 0.0 / 100.0 0.0-100.0 Volt

Outlet fan speed during dehumidification G7 5,0 0.0-100.0 Volt

Starting and end point to open modulating humid. output G8 0.0 / 100.0 0.0-100.0 %

Temperature differential to stop dehumidification G9 5.0 0-99.9 ºC / ºF

Temperature offset to restart dehumidification G9 4.0 0-99.9 ºC / ºF

Disable water drain for set point reduction Ga No No-Yes

Disable drain for extended humidifier standby Ga No No-Yes

Disable minor humidifier alarm messages Ga No No-Yes

High conductivity pre-alarm threshold Gb 1500 0-2000 uS/cm

High conductivity alarm delay Gb 2000 0-2000 uS/cm

Drain time as % of H3 (see humidifier manual) Gc 100 50-200 %

Evaporation time as % of H4 (see humidifier manual) Gc 100 50-200 %

High pressure alarm set point Gd 23.5 -99.9 - 99.9 bar

High pressure alarm differential Gd 1.0 -99.9 - 99.9 bar

Condensing (pressure) set point Ge 14.0 -99.9 - 99.9 bar

Condensing (pressure) differential Ge 2.0 -99.9 - 99.9 bar

Modulating condensing fan speed-up time Ge - Gf 2 0-999 seconds

Condensing (temperature) set point Gf 55.0 -99.9 - 99.9 ºC / ºF

Condensing (temperature) differential Gf 1.0 -99.9 - 99.9 ºC / ºF

Minimum and maximum mod. cond. fan speed Gg 0.0 / 10.0 0-10,0 Volt

Enable high pressure alarm Prevent function Gh - Gi No No-Yes bar

Prevent function set point (pressure) Gh 20.0 -99.9 - 99.9 Bar

Prevent function differential (pressure) Gh 2.0 -99.9 - 99.9 bar

Prevent function set point (temperature) Gi 70.0 -99.9 - 99.9 ºC / ºF

Prevent function differential (temperature) Gi 1.0 -99.9 - 99.9 ºC / ºF

Enable Carel network Master Control function Gj No No-Yes

Rotation mode for units in pLAN network

Gk

Automatic

Automatic,

Time bands,

Operating hours

Number of units set in Standby mode

Gk

0

0-No. unit in Present-

rotation mode

Automatic rotation interval for units in pLAN Gk 24 1-240 Hours

Automatic rotation hours for units in pLAN network Gl 22 0-23 hours

Automatic rotation minutes for units in pLAN network Gl 00 0-59 minutes

Interval in days for automatic rotation in pLAN network Gl 3 1-7 days

Enable Force units in pLAN network Gm No No-Yes

Forcing delay for low and high ambient temperature Gm 3 / 3 0-999 minutes

Low ambient temp. diff. for forcing units in network Gn 8 0-99.9 ºC / ºF

Low ambient temp. offset for forcing units in network Gn 4 0-99.9 ºC / ºF

High ambient temp. diff. for forcing units in network Go 8 0-99.9 ºC / ºF

High ambient temp. offset for forcing units in network Go 4 0-99.9 ºC / ºF

CAREL EXV DRIVERS →

Number of drivers connected F0 0 0-2

Enable backup battery driver 1 F0 No No-Yes

Enable backup battery driver 1 F0 No No-Yes

Type of valve circuit 1 F1 10 (Carel) 0-11 (see 1.5)

Superheating set point circuit 1 F1 6.0 2,0-50,0 ºC

Dead band circuit 1 F1 0 0-9.9 ºC

Type valve circuit 2 F2 10 (Carel) 0-11 (see 1.5)

Superheating set point circuit 2 F2 6.0 2.0-50.0 ºC

Dead band circuit 2 F2 0 0-9.9 ºC

PID control – proportional gain circuit 1 F3 2.5 0.0-99.9

PID control – integration time circuit 1 F3 25 0-999 seconds

PID control – derivative time circuit 1 F3 5,0 0.0-99.9 seconds

Loading...

Loading...