Standard air-conditioning units

Carel Cod. +030221421 – Rel. 1.2 – April, 11, 2003

20

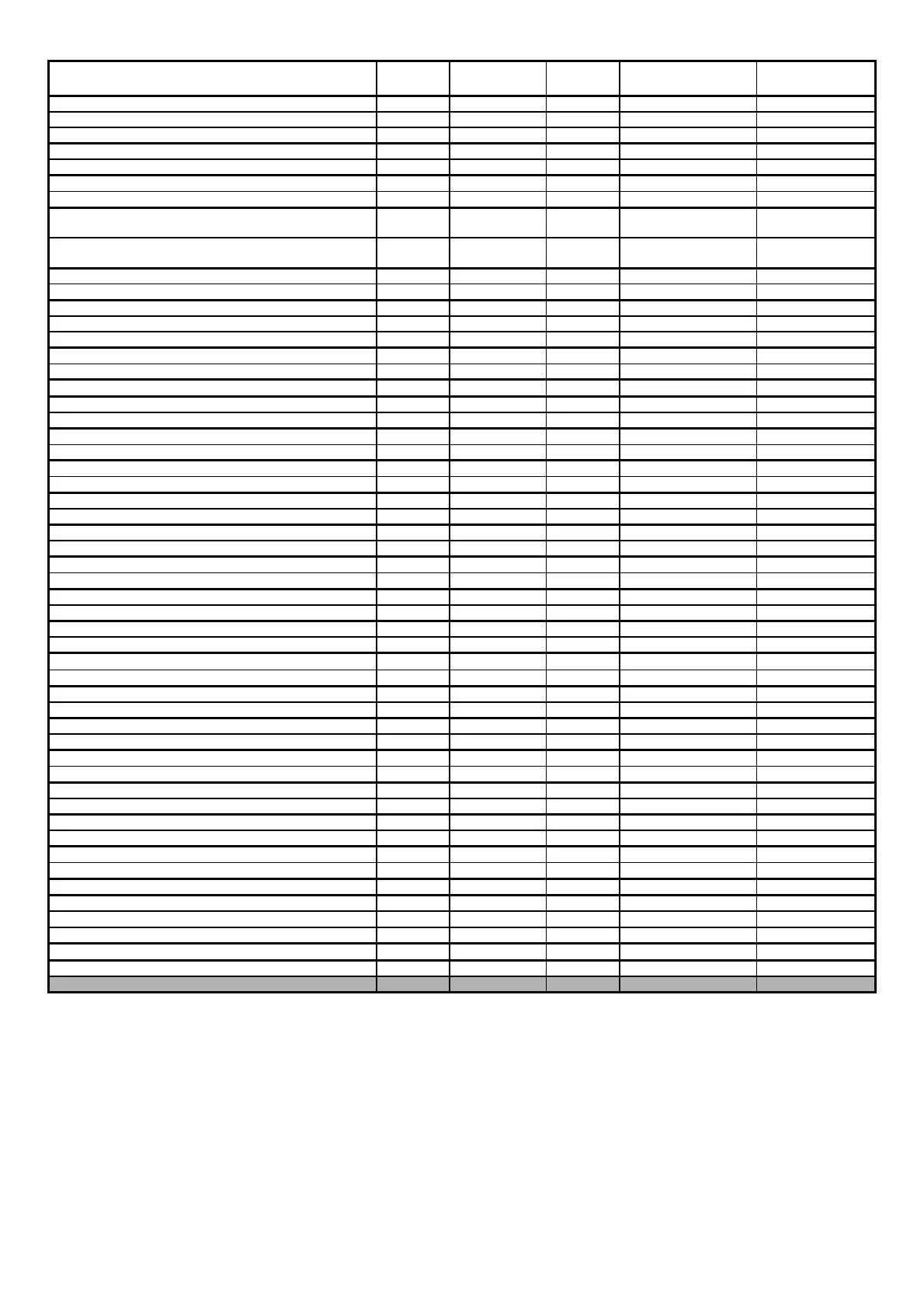

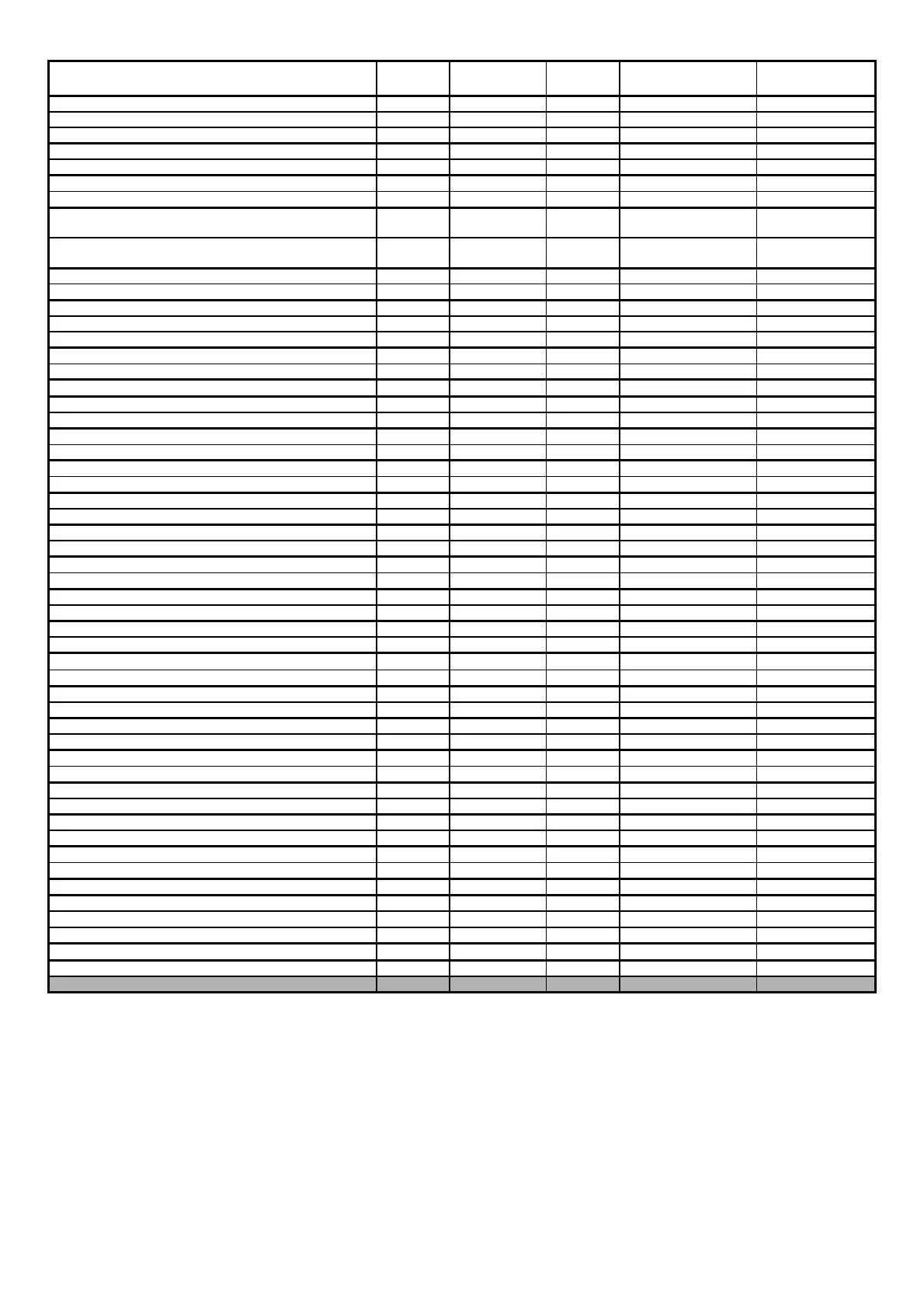

PARAMETER DESCRIPTION SCREEN DEFAULT USER

VALUE

RANGE UOM

PID control – proportional gain circuit 2 F4 2.5 0.0-99.9

PID control – integration time circuit 2 F4 25 0-999 seconds

PID control – derivative time circuit 2 F4 5,0 0.0-99.9 seconds

Threshold for low superheat protection circuit 1 F5 4.0 -4.0 - 10.0 ºC

Prot. threshold integration time, low superheat circuit 1 F5 10 0-255 seconds

Threshold for low superheat protection circuit 2 F6 4.0 -4.0 - 10.0 ºC

Prot. threshold integration time, low superheat circuit 2 F6 10 0-255 seconds

Percentage ratio between cooling capacity and Driver capacity

C 1

F7 60 0-100 %

Percentage ratio between cooling capacity and Driver capacity

C 2

F7 60 0-100 %

LOP threshold F8 -40.0 -70.0 - 50.0 ºC

LOP threshold integration time F8 40 0-255 seconds

MOP start delay F9 30 0-500 seconds

MOP threshold F9 40.0 -50.0 - 99.9 ºC

MOP threshold integration time F9 40 0-255 seconds

High condensing temp. protection threshold Fa 75.0 0-99.9 ºC

Integration time for high condensing temp. threshold Fa 40 0-255 seconds

High suction temperature threshold Fb 30.0 0-100.0 ºC

Custom Valve: minimum steps Fc 0 0-8100

Custom Valve: maximum steps Fc 1600 0-8100

Custom Valve: closing steps Fd 3600 0-8100

Custom Valve: return steps Fd 0 0-8100

Custom Valve: enable extra step in opening Fe No No-Yes

Custom Valve: enable extra step in closing Fe No No-Yes

Custom Valve: operating current Ff 250 0-1000 mA

Custom Valve: holding current Ff 100 0-1000 mA

Custom Valve: frequency Fg 100 32-330 Hertz

Custom Valve: duty cycle Fg 50 0-100 %

Minimum evaporation pressure probe value Fh -0.5 -9.9 - 10.0 Bar

Maximum evaporation pressure probe value Fh 7.0 3.5 - 40.0 Bar

Low superheating alarm delay Fi 0 0-3600 seconds

High suction temperature alarm delay Fi 0 0-3600 seconds

LOP alarm delay Fj 0 0-3600 seconds

MOP alarm delay Fj 0 0-3600 seconds

TIMES →

Outlet fan start and stop delay T0 10 / 20 0-999 seconds

Integration time for P+I temperature control T1 600 0-999 seconds

Travel time for 3 position valve T1 180 0-999 seconds

Low pressure alarm delay T2 180 0-999 seconds

High-low temperature-humidity alarm delays T2 600 0-999 seconds

Alarm relay 7 activation delay, minor alarm T3 0 0-999 seconds

Alarm relay 8 activation delay, serious alarm T3 0 0-999 seconds

Air flow switch alarm delay T4 10 0-999 seconds

Water flow switch alarm delay T4 10 0-999 seconds

Minimum compressor off time T5 180 0-999 seconds

Minimum compressor on time T5 60 0-999 seconds

Delay between compressor starts T6 360 0-999 seconds

Minimum delay between starts of different compressors T6 10 0-999 seconds

Cap. control activation delay T7 10 0-999 seconds

Heater start delay T8 3 0-999 seconds

INITIALISATION →

Enter password for reset Default values function V0 1234 0-9999

Delete BASIC alarm log V1 No No-Yes

Enter new manufacturer password V2 1234 0-9999

Loading...

Loading...