Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

15

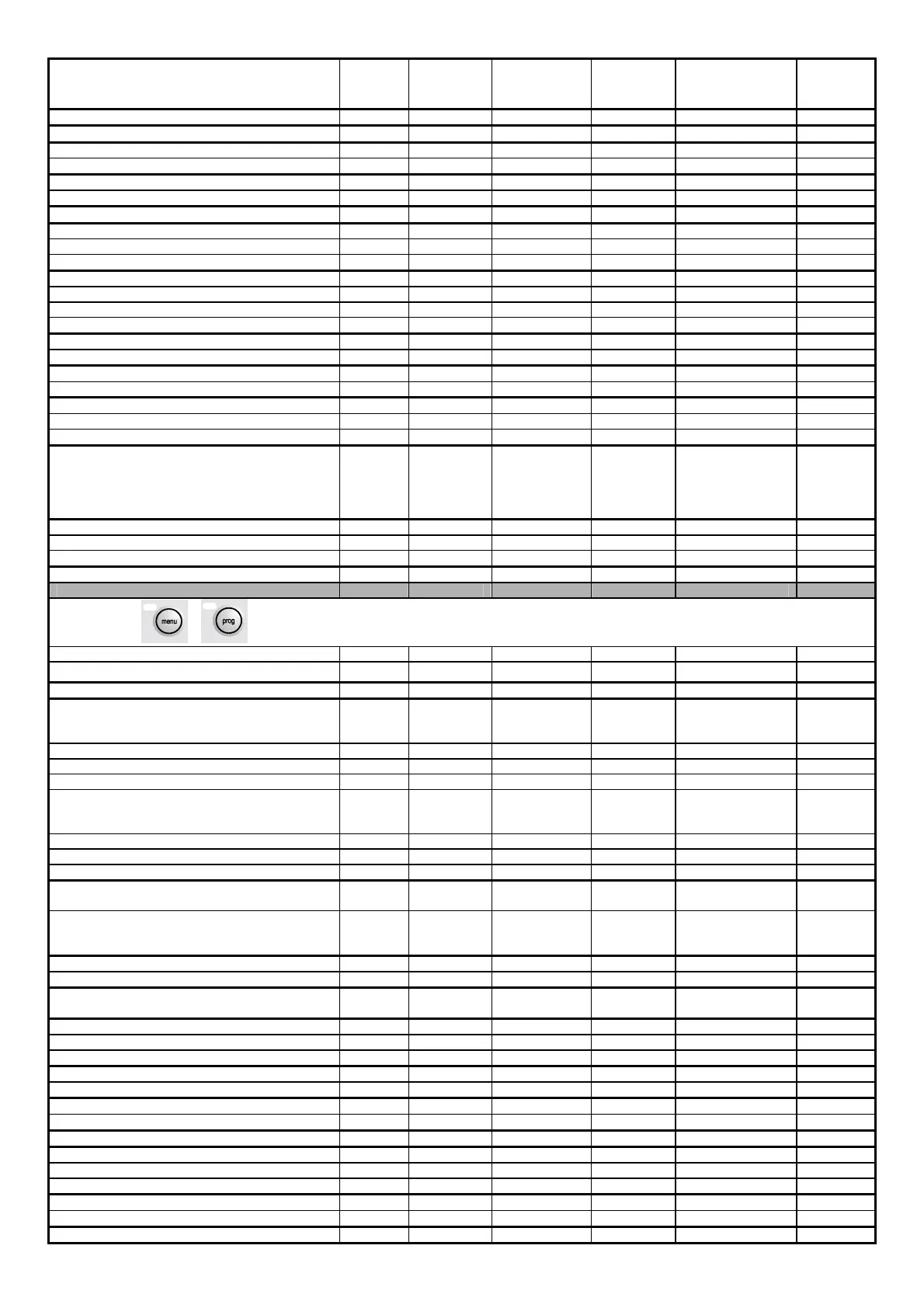

DESCRIPTION OF PARAMETER SCREEN MASTER

SLAVE

FACTORY

VALUE

USER

VALUE

RANGE MEASU-

REMENT

UNIT

Delayed power up between pump and compressors P8 M 5 0 to 999 seconds

Delayed power down of main pump P9 M 5 0 to 999 seconds

Enable remote On/Off Pa M/S N. N/Y

Enable On/Off from supervisor Pa M/S N. N/Y

Enable summer / winter selection from digital input Pb M N. N/Y

Enable summer / winter selection from supervisor Pb M N. N/Y

Enable language mask start-up Pc M/S S N/Y

Type of freecooling control Pd M/S Prop. Prop./Prop+Int.

Integral time for freecooling management Pd M/S 150 0 to 9999 seconds

Freecooling offset on set-point Pd M/S 5.0 0 to 99.9 °C

Minimum freecooling delta Pe M/S 2.0 0 to 99.9 °C

Maximum freecooling delta Pe M/S 10.0 0 to 99.9 °C

Freecooling differential Pe M/S 4.0 2.0 to 99.9 °C

Compressors delay in freecooling Pe M/S 5 0 to 500 minutes

Minimum threshold for freecooling valve start Pf M/S 50 0 to 100 %

Maximum threshold for freecooling valve opening Pf M/S 50 0 to 100 %

Defrosting starts Pg M/S 2.0 -99.9 / 99.9 °C/bar

Defrosting ends Pg M/S 12.0 -99.9 / 99.9 °C/bar

Drip-off time Ph M/S 10 5 to 999 seconds

Delayed defrosting start Ph M/S 1800 0 to 32000 seconds

Maximum defrosting time Ph M/S 300 0 to 32000 seconds

Cycle reversing configuration Pi M/S Comp. always

on

Comp. always ON

Comp. OFF start of

defr. Cmp. OFF end

defr. Comp. OFF

start/end

Card identification number for supervision network Pj M/S 1 0 to 200

Card communication speed for supervision network Pj M/S 19200 1200 to 19200 bps

Selection of communication serial network Pj M/S Carel Carel / Modbus

New user password inputting Pk M/S 1234 0 to 9999

+

Constructor password inputting Z0 M/S 1234 0 to 9999

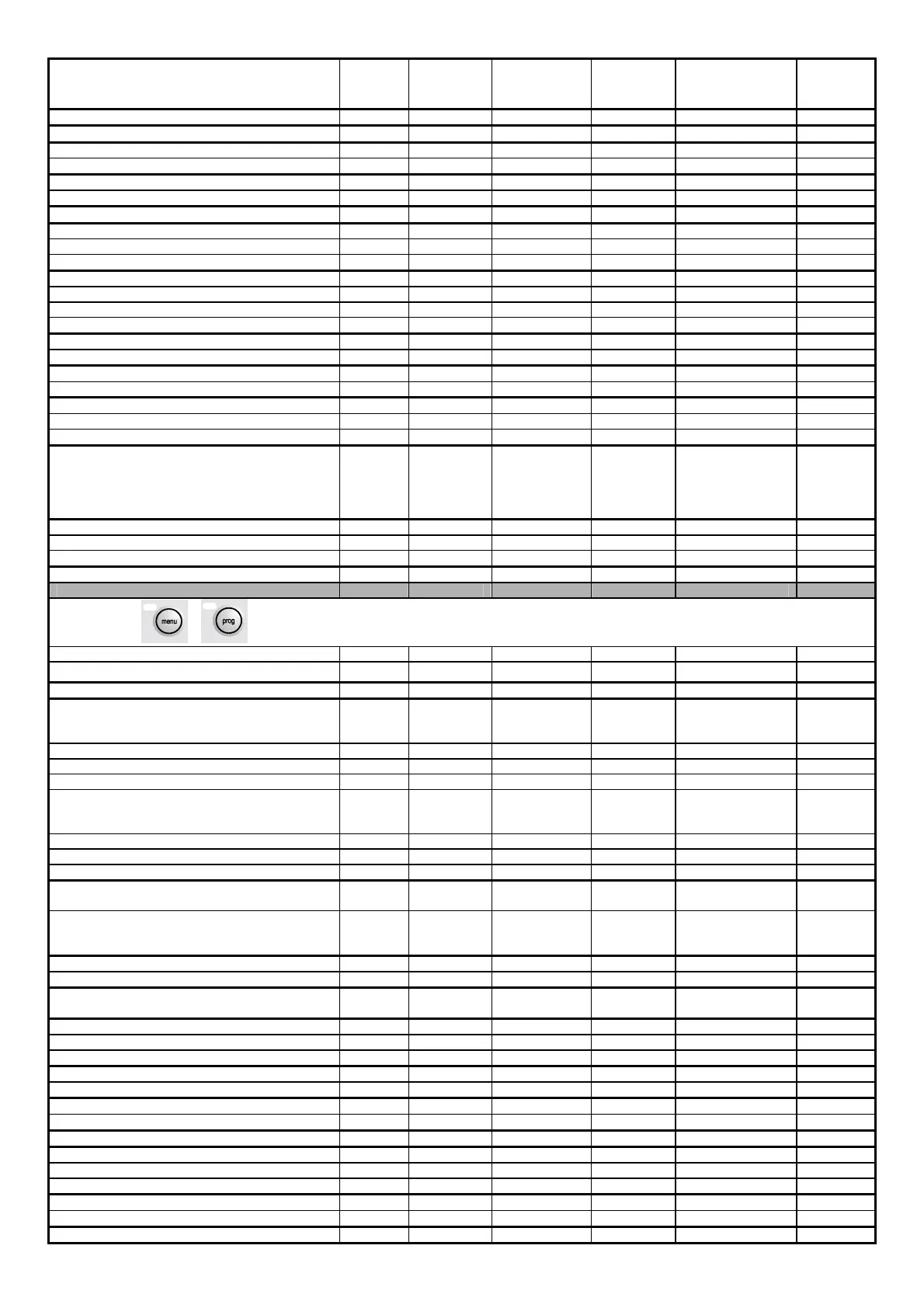

CONFIGURATION →

Unit configuration C1 M/S 0 0 to 5

Enable probe B1 C2 M/S Y (if pCO2)

N (if pCO1)

Y (if pCOC)

N/Y

Enable probe B2 C2 M/S N. N/Y

Enable probe B3 C2 M/S N. N/Y

Enable probe B4 C2 M/S N. N/Y

Enable probe B5 C2 M/S N (if pCO2)

Y (if pCO1)

N (if pCOC)

N/Y

Enable probe B6 C2 M/S N. N/Y

Enable probe B7 C2 M/S N. N/Y

Enable probe B8 C2 M/S N. N/Y

Generic probe generic configuration (B4 on pCO1, B5

on pCOC, B6 on pCO2)

C3 M/S None No Current Voltage

external Set-point

Type of generic probe C3 M/S 0 - 1 V 0-1 V

0-10 V

4-20mA

Generic probe lower limit C4 M/S 0.0 -999.9 to 999.9 °C/V/A

Generic probe upper limit C4 M/S 0.0 -999.9 to 999.9 °C/V/A

Probe types for analogue inputs 1 and 2 (for pCO1

cards only)

C5 M/S 4-20mA 4-20mA / 0-5V

Type of delivery temperature probe C6 M/S Ntc Ntc / 4-20mA

Delivery probe lower limit C6 M/S -30.0 -999.9 to 999.9 °C

Delivery probe upper limit C6 M/S 150.0 0.0 to 999.9 °C

High pressure probe lower limit C7 M/S 00.0 -99.9 to 99.9 bar

High pressure probe upper limit C7 M/S 30.0 -99.9 to 99.9 bar

Low pressure probe lower limit C8 M/S -0.5 -99.9 to 99.9 bar

Low pressure probe upper limit C8 M/S 7.0 -99.9 to 99.9 bar

Enable double set-point C9 M Disabled Disabled / Enabled

Number of drivers present Ca M/S 0 0 to 2

Number of compressors present Ca M/S 1 1 to 4

Compressor rotation Ca M S N/Y

Type of capacity control Cb M/S Steps Step/Modul.

Number of steps per compressor Cb M/S 4 1 to 4

Enable starting restrictions Cc M/S N. N/Y

Loading...

Loading...