Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

16

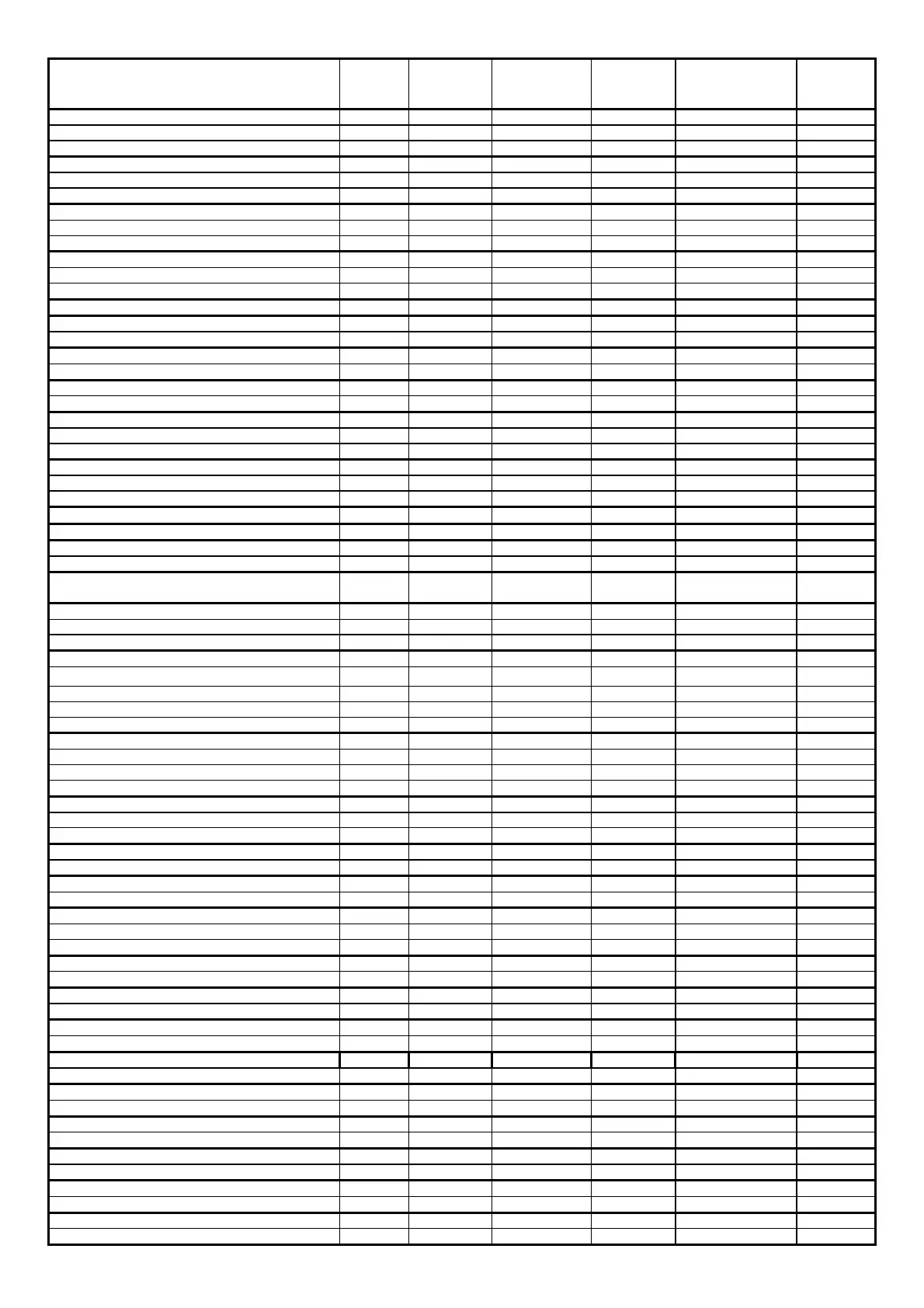

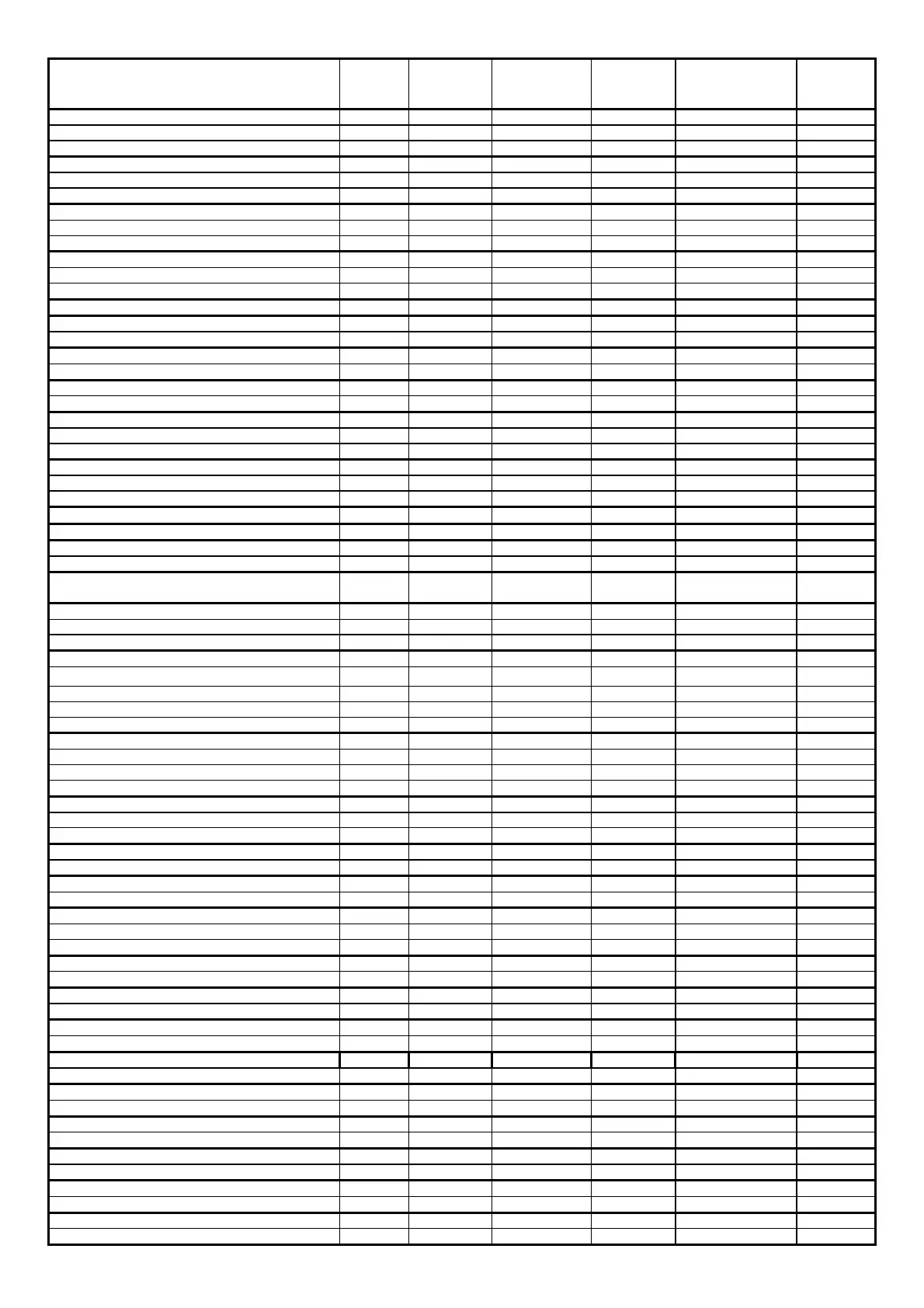

DESCRIPTION OF PARAMETER SCREEN MASTER

SLAVE

FACTORY

VALUE

USER

VALUE

RANGE MEASU-

REMENT

UNIT

Step 1 - Relay 1 logic Cd M/S ON OFF/ON

Step 1 - Relay 2 logic Cd M/S OFF OFF/ON

Step 1 - Relay 3 logic Cd M/S OFF OFF/ON

Step 2 - Relay 1 logic Ce M/S OFF OFF/ON

Step 2 - Relay 2 logic Ce M/S OFF OFF/ON

Step 2 - Relay 3 logic Ce M/S ON OFF/ON

Step 3 - Relay 1 logic Cf M/S OFF OFF/ON

Step 3 - Relay 2 logic Cf M/S ON OFF/ON

Step 3 - Relay 3 logic Cf M/S OFF OFF/ON

Step 4 - Relay 1 logic Cg M/S OFF OFF/ON

Step 4 - Relay 2 logic Cg M/S OFF OFF/ON

Step 4 - Relay 3 logic Cg M/S OFF OFF/ON

Enable step 1 special management Ch M/S N. N/Y

Stand-by configuration for relay 6 Ci M/S OFF OFF/ON

Stand-by configuration for relay 7 Ci M/S ON OFF/ON

Reducing configuration for relay 6 Cj M/S ON OFF/ON

Decrementing configuration for relay 7 Cj M/S ON OFF/ON

Incrementing configuration for relay 6 Ck M/S OFF OFF/ON

Incrementing configuration for relay 7 Ck M/S OFF OFF/ON

Pulse period for modulating configuration Cl M/S 6 0 to 99 seconds

Minimum decrementing pulse Cl M/S 1.5 0 to 99.9 seconds

Maximum decrementing pulse Cl M/S 3.0 0 to 99.9 seconds

Derivation time for modulating configuration Cm M/S 3 seconds

Minimum decrementing pulse Cm M/S 1.5 0 to 99.9 seconds

Maximum decrementing pulse Cm M/S 3.0 0 to 99.9 seconds

Decrement forcing time at compressor start Cn M/S 20 0 to 999 seconds

Enable solenoid forcing when compressor OFF Co M/S N. N/Y

Enable pump - down Cp M/S N. N/Y

Minimum pump - down time Cp M/S 50 0 to 999 seconds

Configuration of compressor power level in case of

forced capacity control.

Cq M/S Max. power Max. power / Min.

power

Enable condensation Cr M/S No NO/YES

Type of condensation control Cr M/S Inverter Inverter / Steps

Number of fans per condenser Cr M/S 1 1 to 2

Enable clock card Cs M/S Disabled Disabled / Enabled

PARAMETERS →

Starting restrictions - low pressure G0 M/S

Starting restrictions - high pressure G0 M/S

Starting restrictions - pressure equalisation G0 M/S

Enable high pressure prevention G1 M/S N. N/Y

Type of high condensation prevention G1 M/S Pressure Press / Temp

Condensation set-point G1 M/S 20.0 0 to 99.9 bar/ °C

High condensation differential G1 M/S 2.0 0 to 99.9 bar/ °C

Enable delivery prevention G2 M/S N. N/Y

Delivery prevention set-point G2 M/S 90.0 0 to 999.9 °C

Delivery prevention differential G2 M/S 5.0 0 to 99.9 °C

Antifreeze prevention set point G3 M/S 6.0 -99.9 to 99.9 °C

Antifreeze prevention differential G3 M/S 1.0 0 to 99.9 °C

Condensation set-point G4 M/S 14.0 -999.9 to 999.9 bar/ °C

Condensation differential G4 M/S 2.0 -999.9 to 999.9 bar/ °C

Inverter maximum speed G5 M/S 10.0 0.0 to 10.0 V

Inverter maximum speed G5 M/S 3.0 0.0 to 10.0 V

Maximum speed time G5 M/S 10 0 to 99 seconds

Enable serious alarm G6 M/S N. N/Y

Enable phase monitor alarm G6 M/S N. N/Y

Enable evaporator flow-switch alarm G7 M/S N. N/Y

Enable condenser flow-switch alarm G7 M/S N. N/Y

Alarm set-point for delivery temperature probe G8 M/S 120.0 0 to 999.9 °C

Alarm differential for delivery temperature probe G8 M/S 5.0 0 to 99.9 °C

High pressure probe alarm set-point G9 M/S 21.0 0 to 99.9 bar

High pressure probe alarm differential G9 M/S 2.0 0 to 99.9 bar

Low pressure probe alarm set-point Ga M/S 1.0 -99.9 to 99.9 bar

Low pressure probe alarm differential Ga M/S 0.5 -99.9 to 99.9 bar

Alarm set-point: difference between high and low pressure Gb M/S 6.0 0 to 99.9 bar

Delayed start due to low pressure difference alarm Gb M/S 20 0 to 999 seconds

High voltage alarm set-point Gc M/S 440.0 0 to 999.9 V

High voltage alarm differential Gc M/S 5.0 0 to 99.9 V

High current alarm set-point Gd M/S 90.0 0 to 999.9 A

High current alarm differential Gd M/S 5.0 0 to 99.9 A

Antifreeze set point Ge M/S 3.0 0 to 999.9 °C

Antifreeze differential Ge M/S 1.0 0 to 99.9 °C

Loading...

Loading...