Standard Chiller/HP modulare per compressore a vite con driver CAREL

Cod.: +030221241 Rel. 1.0 dated 25 September 03

17

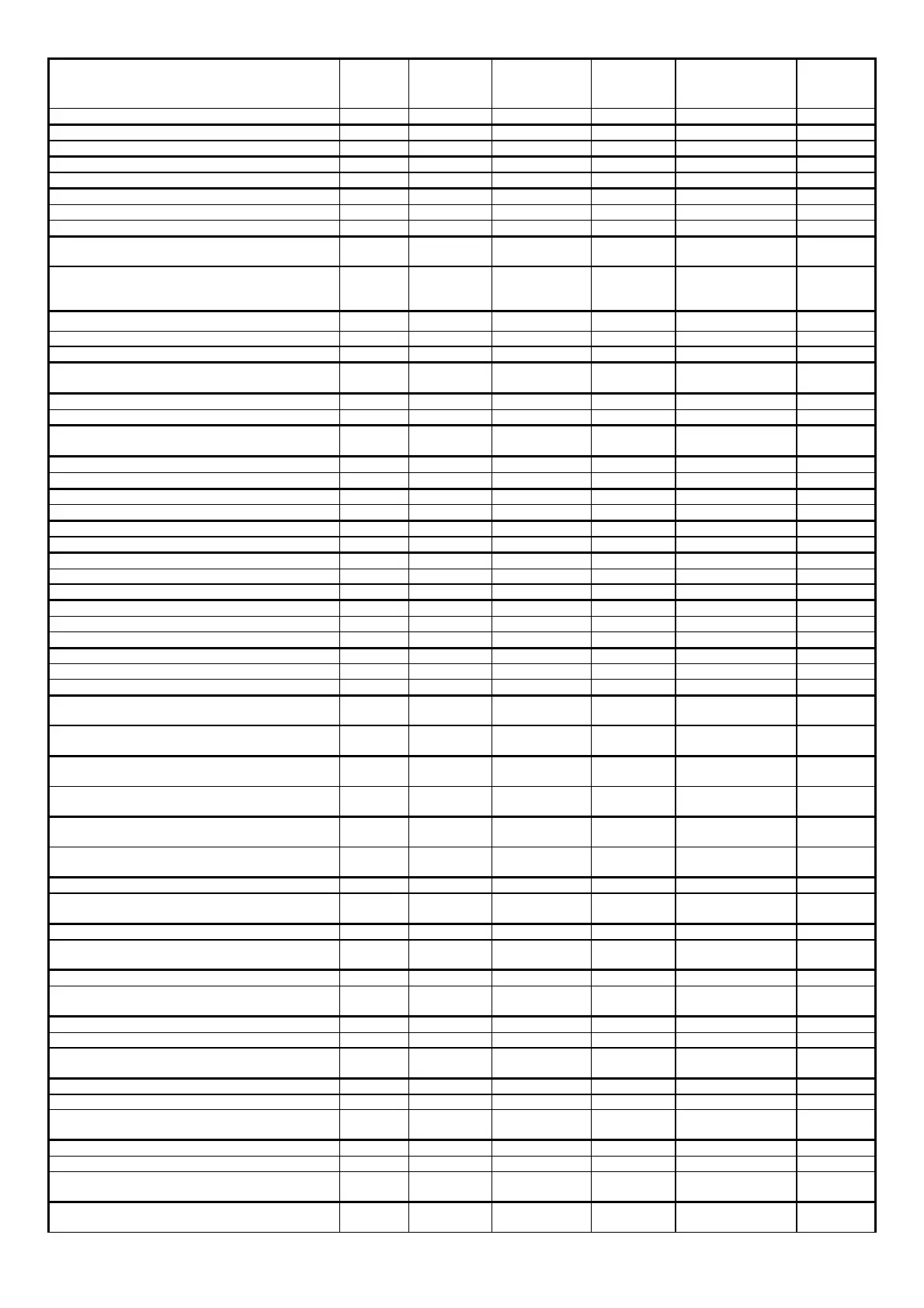

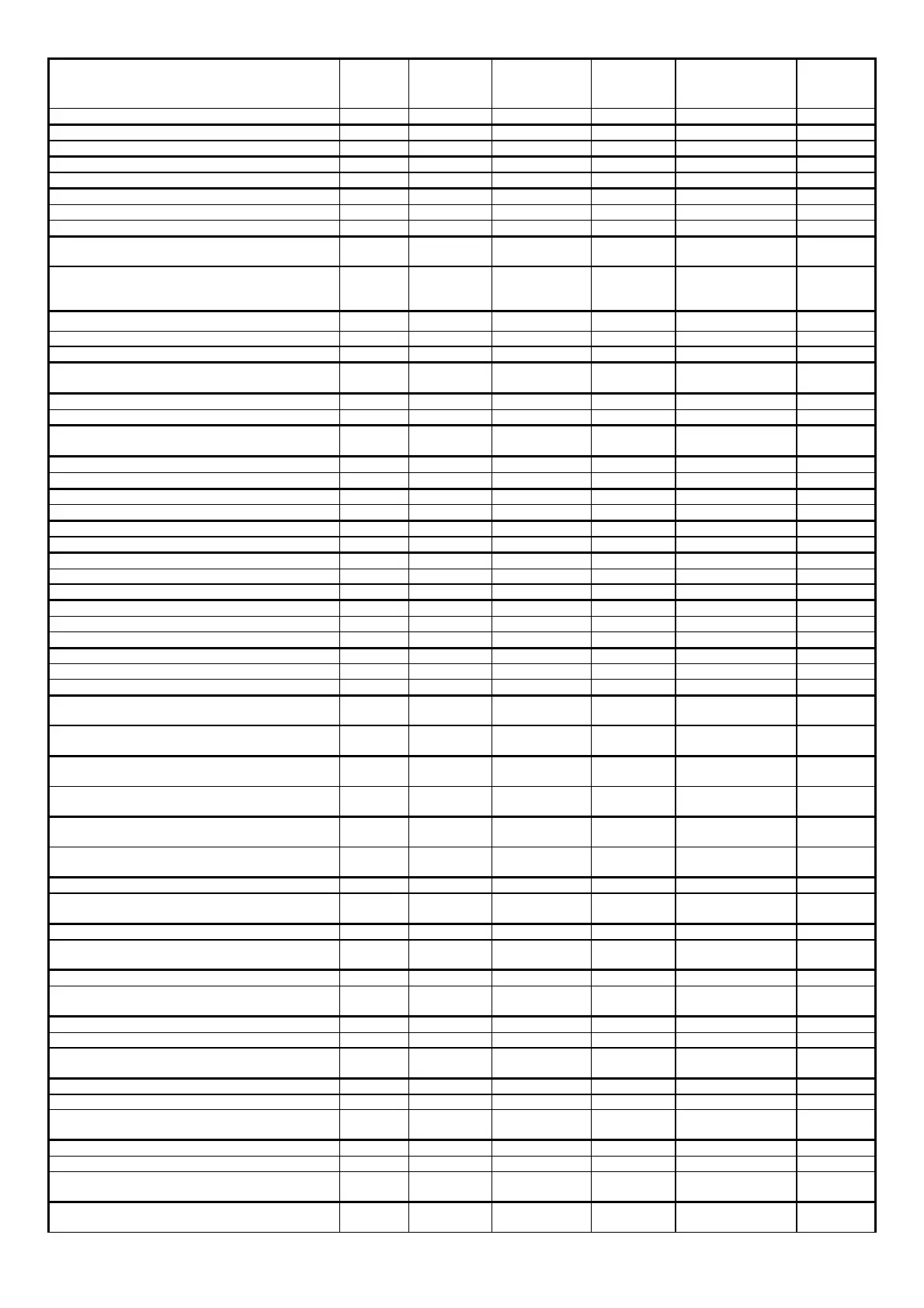

DESCRIPTION OF PARAMETER SCREEN MASTER

SLAVE

FACTORY

VALUE

USER

VALUE

RANGE MEASU-

REMENT

UNIT

Pump status in case of antifreeze alarm Gf M Pump ON Pump ON /Pump OFF

Solenoid-valve management set-point Gg M/S 80.0 0 to 999.9 °C

Solenoid-valve management differential Gg M/S 10.0 0 to 99.9 °C

Antifreeze heater set point Gh M/S 5.0 0 to 99.9 °C

Antifreeze heater differential Gh M/S 1.0 0 to 99.9 °C

Cycle reversing valve logic Gi M/S N.O. N.O. / N.C.

Type of freecooling control Gi M/S 0/10V ON-OFF/0-10V

Antifreeze temperature Gi M/S -2.0 -99.9 to 99.9 °C

Defrosting probe configuration Cj M/S Pressure

switches

Temperature

Pressure switches

Type of overall defrosting Cj M/S Simultaneous Simultaneous

Separate

Independent

CAREL EXV DRIVERS →

Driver 1 valve type F0 M/S Custom 0-11 (see page 8)

Enable driver 1 battery F0 M/S N. N/Y

Percentage relationship between Refrigerating power

and Driver 1 power

F1 M/S 60 0 to 100 %

Driver 2 valve type F2 M/S Custom 0-11 (see page 8)

Enable driver 2 battery F2 M/S N. N/Y

Percentage relationship between Refrigerating power and

Driver C2 power

F3 M/S 60 0 to 100 %

Driver 1 superheat set point during chiller operation F4 M/S 6.0 2.0 to 50.0 °C

Driver 1 dead band during chiller operation F4 M/S 0 0 to 9.9 °C

Driver 1 superheat set point during defrost. operation F5 M/S 6.0 2.0 to 50.0 °C

Driver 1 dead band during defrost. operation F5 M/S 0 0 to 9.9 °C

Driver 2 superheat set point during heat pump operation F6 M/S 6.0 2.0 to 50.0 °C

Driver 2 dead band during heat pump operation F6 M/S 0 0 to 9.9 °C

Driver 2 superheat set point during chiller operation F7 M/S 2.5 0.0 to 99.9

Driver 1 integral time during chiller operation F7 M/S 25 0 to 999 seconds

Driver 1 derivative time during chiller operation F7 M/S 2.0 0.0 to 99.9 seconds

Driver 2 proportional gain during defrost. operation F8 M/S 2.5 0.0 to 99.9

Driver 1 integral time during defrost. operation F8 M/S 25 0 to 999 seconds

Driver 1 derivative time during defrost. operation F8 M/S 2.0 0.0 to 99.9 seconds

Driver 2 proportional gain during heat pump operation F9 M/S 2.5 0.0 to 99.9

Driver 2 integral time during heat pump operation F9 M/S 25 0 to 999 seconds

Driver 2 derivative time during heat pump operation F9 M/S 2.0 0.0 to 99.9 seconds

Threshold for driver 1 low superheat protection

during chiller operation.

Fa M/S 4.0 -4.0 to 10.0 °C

Integral time for driver 1 low superheat protection

super heat in chiller operation

Fa M/S 1.0 0 to 25.5 seconds

Threshold for driver 1 low superheat protection

during defrosting operation.

Fb M/S 4.0 -4.0 to 10.0 °C

Integral time for low alarm protection super heat

driver 1 during defrost operation

Fb M/S 1.0 0 to 25.5 seconds

Threshold for driver 2 low super heat during pump

operation

Fc M/S 4.0 -4.0 to 10.0 °C

Threshold integral time for driver 2 low super

protection during heat pump operation

Fc M/S 1.0 0 to 25.5 seconds

Threshold for LOP protection during chiller operation Fd M/S -40.0 -70.0 to 50.0 °C

Threshold Integral time for LOP protection during

chiller. operation

Fd M/S 4.0 0 to 25.5 seconds

Threshold for LOP protection during heat pump operation Fe M/S -40.0 -70.0 to 50.0 °C

Threshold integral time for LOP protection during heat

pump operation

Fe M/S 4.0 0 to 25.5 seconds

Threshold for LOP protection during defrost. operation Ff M/S -40.0 -70.0 to 50.0 °C

Integral time of threshold for LOP protection during

defrost. operation

Ff M/S 4.0 0 to 25.5 seconds

Delayed start MOP protection during chiller operation Fg M/S 30 0 to 500 seconds

Threshold for MOP protection during chiller operation Fg M/S 40.0 -50.0 to 99.9 °C

Threshold Integral time for LOP protection during

chiller. operation

Fg M/S 4.0 0 to 25.5 seconds

Delayed start MOP protection during heat pump operation Fh M/S 30 0 to 500 seconds

Threshold for MOP protection during heat pump operation Fh M/S 40.0 -50.0 to 99.9 °C

Threshold integral time for MOP protection during

heat pump operation

Fh M/S 4.0 0 to 25.5 seconds

Delayed start MOP protection during chiller operation Fi M/S 30 0 to 500 seconds

Threshold for MOP protection during chiller operation Fi M/S 40.0 -50.0 to 99.9 °C

Threshold Integral time for LOP protection during

chiller. operation

Fi M/S 4.0 0 to 25.5 seconds

Threshold for condensation high temperature

protection during chiller operation

Fj M/S 75.0 0 to 99.9 °C

Loading...

Loading...