51

ENG

µchiller +0300053EN rel. 2.2 - 14.12.2021

Functions

5. FUNCTIONS

5.1 Temperature control

Chiller can control either the unit’s return or delivery water temperature. The return (from user) and delivery (to user) water

temperature probes can be installed on any of the channels. See the Installation chapter.

5.1.1 PID control

Two types of PID control are available:

• PID control at start-up;

• PID control in operation.

For each type of PID control, the following parameters can be set:

• Control probe (return or delivery);

• Proportional gain (Kp);

• Integral time (action disabled when time set to 0);

• Derivative time (action disabled when time set to 0).

The control set point and the operating mode (heating / cooling) are the same for both control types:

• control at start-up is aimed at preventing excess capacity being called. Indeed, as when starting the exact status of the units

(loads) is not known, but rather only the temperature, capacity needs to be delivered gradually, awaiting the reaction from

the system. Control can be applied to the water return temperature, using a low gain and a suffi ciently high integral time,

greater than the system time constant (120- 180 s, considering a system time constant of at least 60 s, corresponding to a

minimum water content of 2.5 l/kW).

• control in operation needs to be more reactive, so as to respond quickly to any variations in load and keep the delivery water

temperature as close as possible to the set point. In this case, the time constant depends on the response of the compres-

sor-evaporator system, and is in the order of a few tens of seconds (slower with tube bundle evaporators, faster with plate

evaporators).

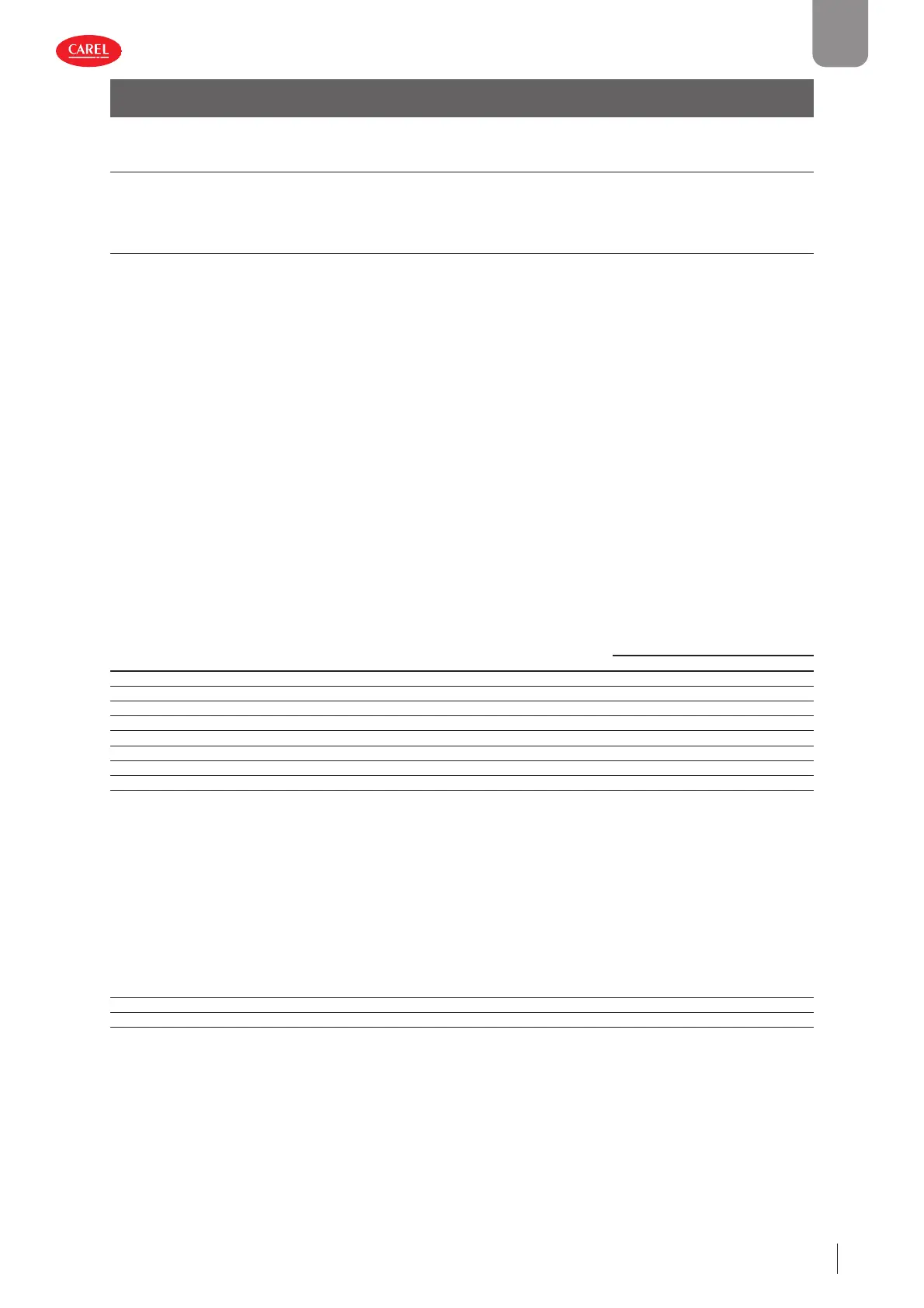

The following table shows the recommended values (to be calibrated if necessary during system commissioning), according to

the type of evaporator used

Code Description

Evaporator

Tube bundle Plate

U036 Control probe at start-up - 0=Return 1=Delivery Return Return

U039 PID at start-up: Kp 6.0 6.0

U040 PID at start-up: Ti - 0: integral action disabled 180 s 180 s

U041 PID at start-up: Td - 0: derivative action disabled 0 s 0 s

U038 Control probe in operation - 0=Return 1=Delivery Delivery Delivery

U042 PID in operation: Kp 10.0 10.0

U043 PID in operation: Ti - 0: integral action disabled 120 s 120 s

U044 PID in operation: Td - 0: derivative action disabled 3 s 3 s

Tab. 5.a

The control sequence is as follows:

1. when the unit is Off , both PID controls are disabled;

2. when the unit starts, following the set user pump – compressor delay, the PID at start-up is enabled and generates a capa-

city request (percentage) that is then processed so as to activate the compressors;

3. if this request is suffi cient, one compressor will be started;

4. once the compressor has started, after a set time, control switches from PID at start- up to PID in operation;

5. when the controller requests deactivation of the compressors, these are enabled to stop;

6. after the last compressor has been stopped, restart is managed using the PID at start-up.

If the delay between PID at start-up/in operation is set to 0, PID control in operation will always be active.

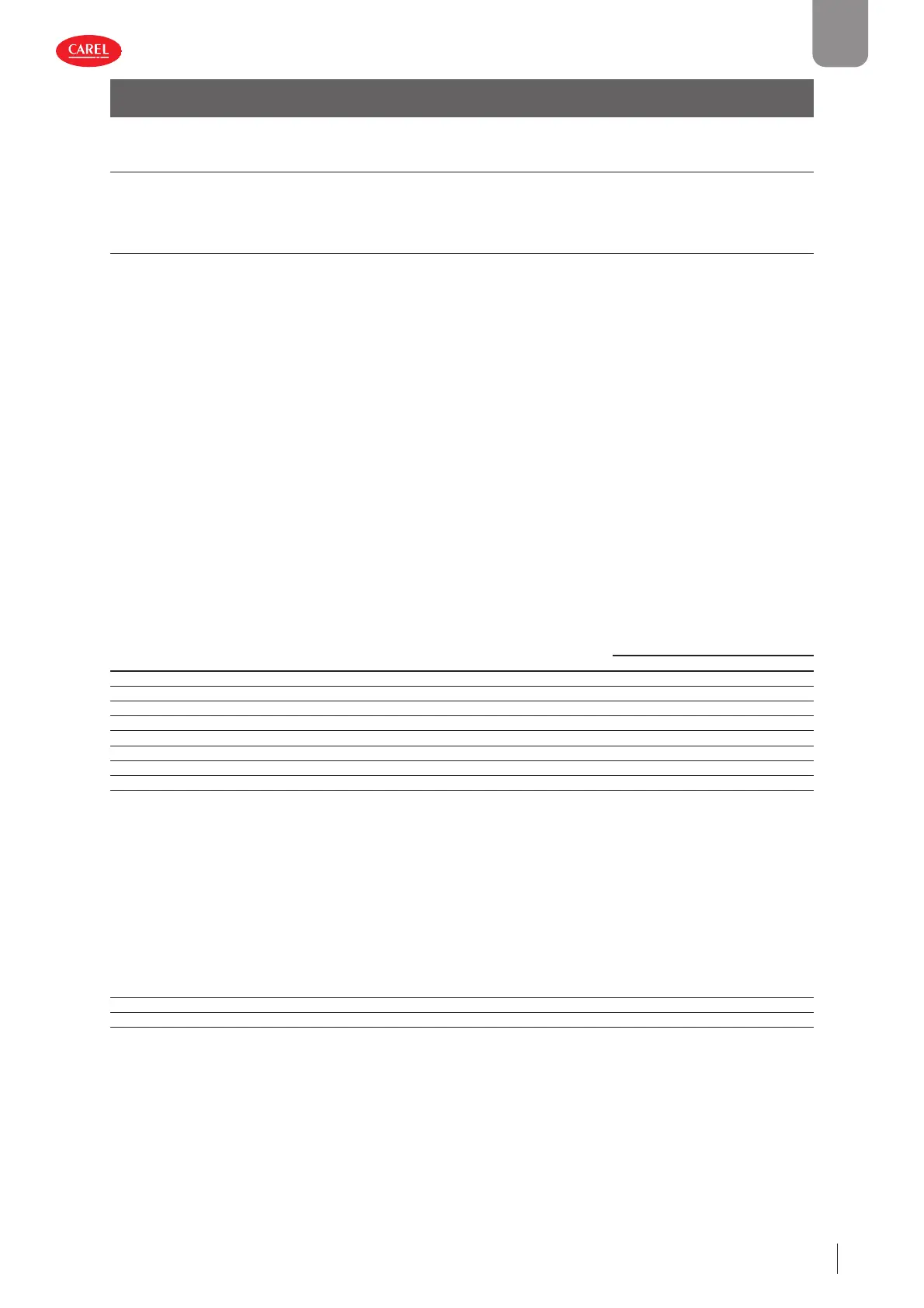

User Code Description Def Min Max UOM

S U047 Compressor activation delay after user pump 30 0 999 s

S U037 PID control delay at start-up/operation 180 0 999 s

Tab. 5.b

Loading...

Loading...