LB-00193-20.EN Pag. 14 10-02-09

SPECIAL FUNCTIONS FOR MACHINE CALIBRATION

ONLY ASSISTANCE SERVICE PERSONNEL AUTHORIZED BY CARIMALI SPA. ARE PERMITTED TO ENABLE THE USE OF

THESE FUNCTIONS.

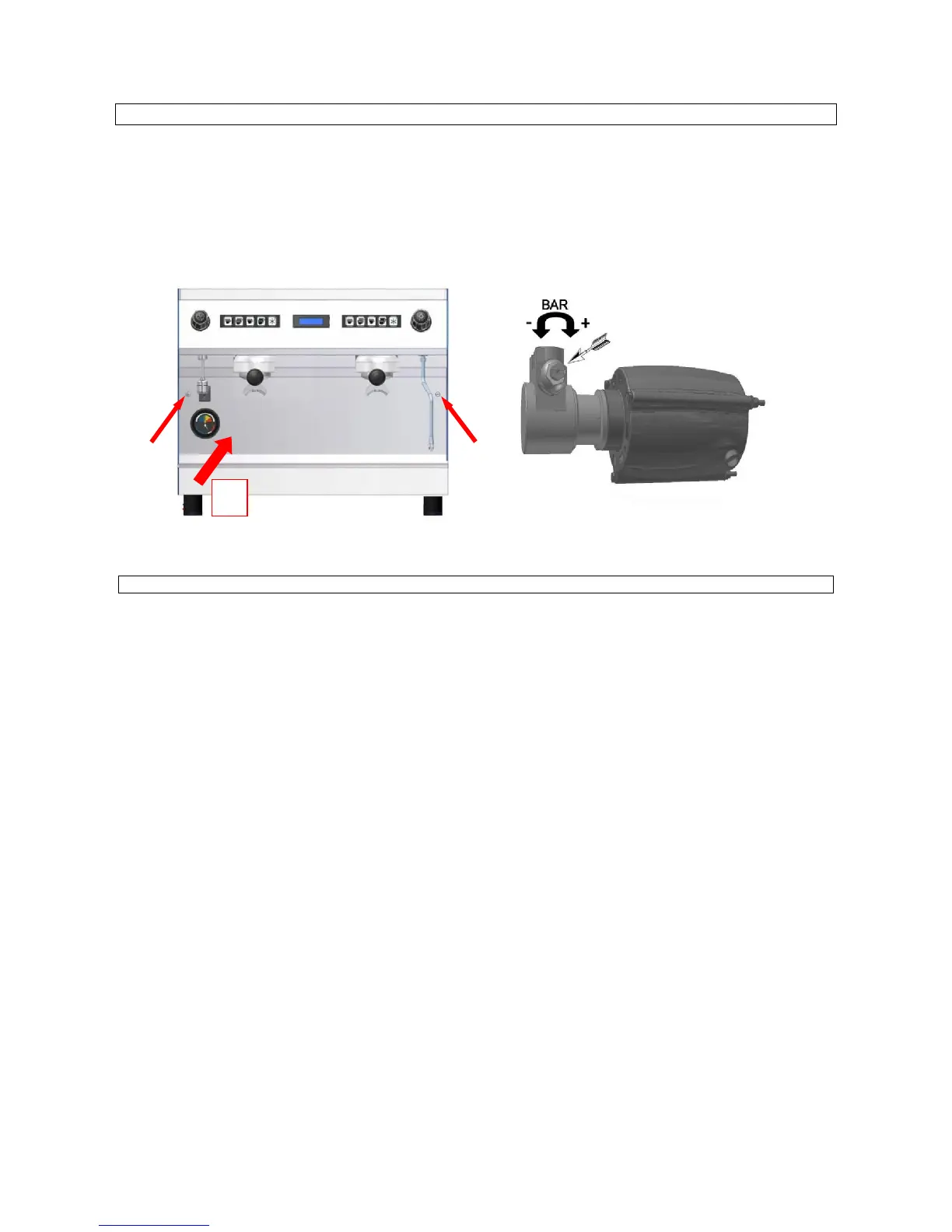

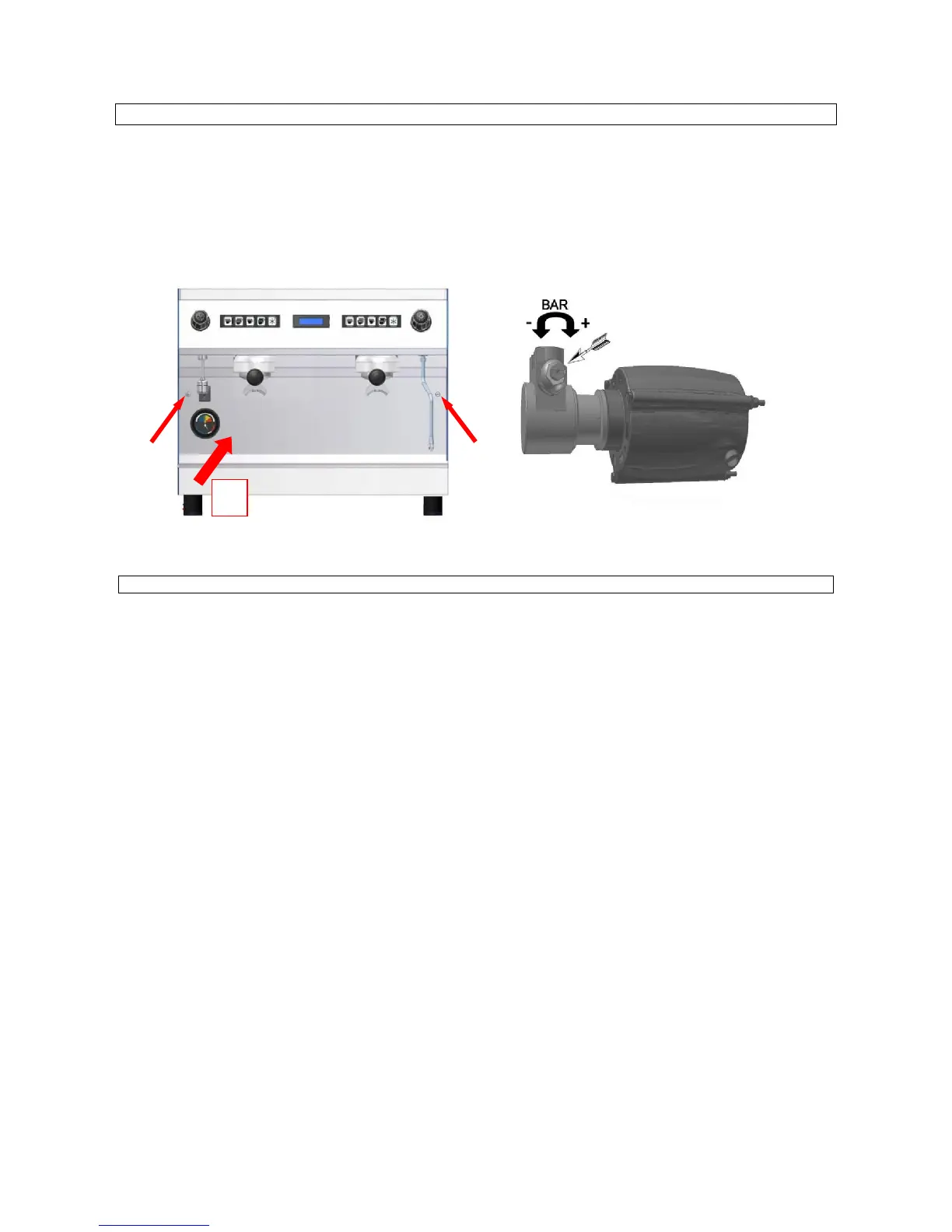

1) Calibrating the coffee dispensing pressure ( pump pressure)

To calibrate the water pump, remove the drip tray (1) then the front panel (2) and calibrate the pump by turning the adjustment,

clockwise to increase the pump pressure or anticlockwise to reduce pressure.

The pressure is pre-calibrated at the factory at 8/9 bars.

1. Boiler filling alarm

Causes: the stage of boiler fillings has exceeded the maximum time of 120 seconds; the level of the probe (SLC) has not been reached.

Result: the machine is OFF, and all the keypad LEDs flash simultaneously:

Solution: carry out the following controls.

Level probe (SLC) is dirty, so isolated from the water (the complete filling of the boiler is checked)

no water from mains

low water pressure

faulty motor pump

faulty filler solenoid valve

incorrect electrical connections (level probe (SLC) cord stopped.

Turn the machine OFF and back ON to erase the alarm

2. Turbine alarm.

Cause: the volume meter is not sending signals to the control unit within a time-out of 5 seconds.

Result: delivery continues up to a time-out of 240 seconds or until the selected key is pressed, and all the LEDs on the push-button

panels flash (medial flashes)

Solution: carry out the following controls.

No water from mains (coffee is not dispensed)

clogged group piston filters (coffee is not dispensed)

faulty group solenoid valve (coffee is not dispensed)

clogged entrance filters (coffee is not dispensed)

blocked or faulty volume meter (coffee dispensed continuously)

faulty electrical connection (coffee dispensed continuously).

If the coffee is dispensed continuously, use the machine as if it were manual: press the required key to start up the dose, then press the

same key to stop the dose being dispensed, after checking the amount in the cup.

Loading...

Loading...