LB-00193-20.EN Pag. 15 10-02-09

3. Safety Klixon operation.

Cause: The temperature of the boiler has reached the limit of 145°C.

Result: the heating is interrupted.

Solution: carry out the following controls.

Level probe (SLC) earthed

Faulty temperature probe

Faulty Triac

Defective inlet solenoid valve

WARNING: To activate the safety Klixon, it is necessary to press the button placed at the centre of the thermostat itself.

4. Safety valve operation.

Cause: overpressure in steam boiler

Result: the 1.7-1.9 bar safety valve opens and releases steam in the upper part of the machine.

Solution: carry out the following controls:

Triac earthed

Faulty temperature probe

5. Anti-vacuum valve.

The anti-vacuum valve is installed on the boiler and prevents any air remaining during

the loading phase and a depression being created during the heating phase.

6. Non-return valve.

The non-return valve is installed between the loading solenoid valve and the boiler

and has the following function:

During the loading phase it opens by means of the water pressure, letting the water enter

into the boiler. Once the loading phase is over, it closes preventing the water in the

steam boiler from returning to the water supply network.

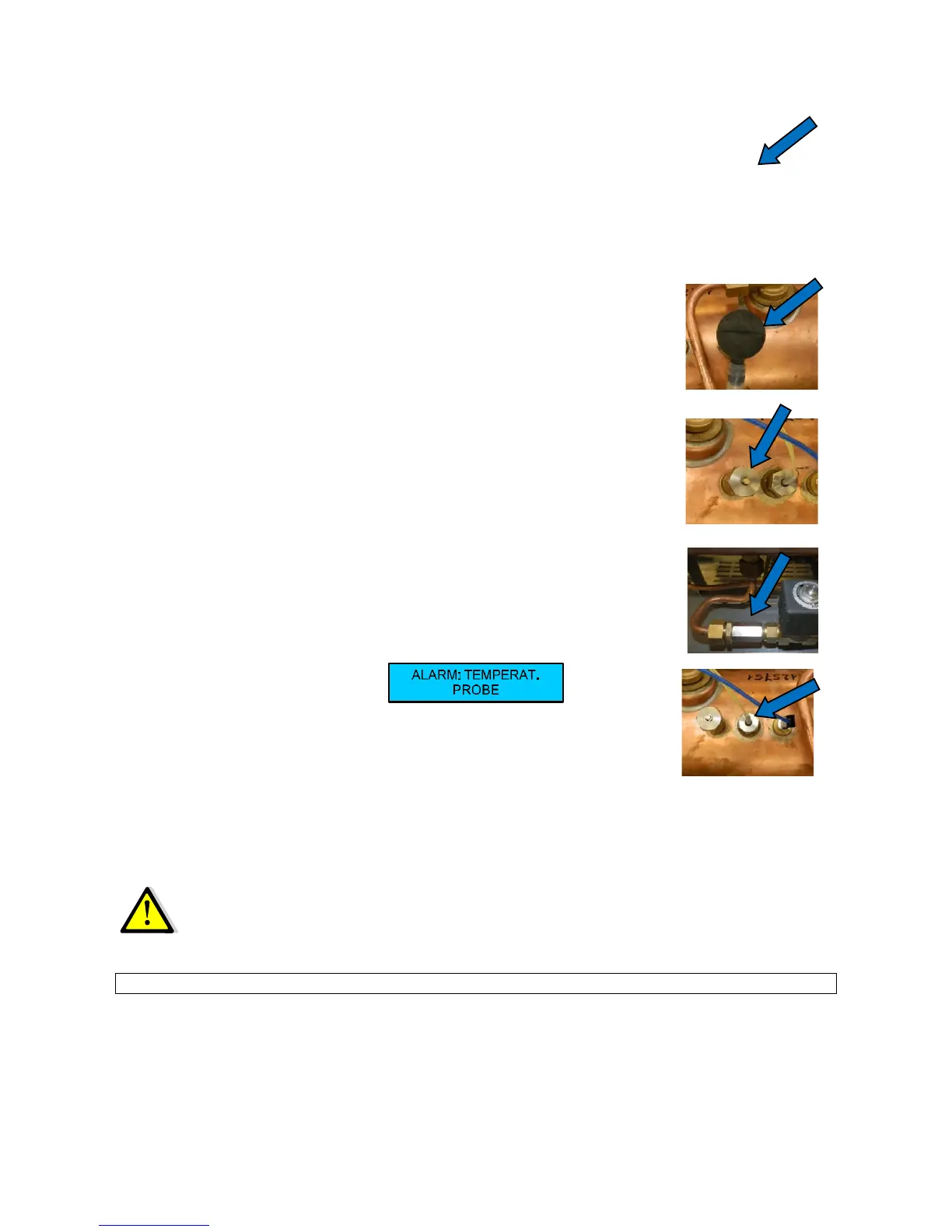

7. Temperature probe alarm

First case: the temperature inside the boiler has reached the maximum value of 131°C

Effect: boiler heating is interrupted and drink keys are disabled.

Solution: switch off the machine ( OFF ), check and if needed replace the “ Triac”.

Second case: the temperature probe is defective and send a 0 Ohm (short circuit) signal to the pc board.

Effect: boiler heating is interrupted and drink keys are disabled.

Solution: switch off the machine OFF, then replace the temperature probe and switch the machine ON.

Third case: the temperature probe is defective and send a 154 Ohm or more (open circuit) signal to the pc board.

Effect: boiler heating is interrupted and drink keys are disabled.

Solution: switch off the machine OFF, then replace the temperature probe and switch the machine ON.

Attention: Periodically check the electric wiring of the Triac. A wrong or incomplete wiring may

cause a pc board breakage.

SUGGESTED ORDINARY MAINTENANCE

Routine maintenance must be carried out daily by authorized staff as specified in the specific chapters of instructions machine.

Cleaning of the coffee outlet by means of the provided special brush is part of the daily maintenance.

Special maintenance must be carried out periodically by the CARIMALI authorized service centre in the following way:

Replace filter holder gasket every 3-6 months

Replace the steam-water valve gasket every 6 months

Replace the steam nozzle joint gasket every 6-12 months

Loading...

Loading...