EN

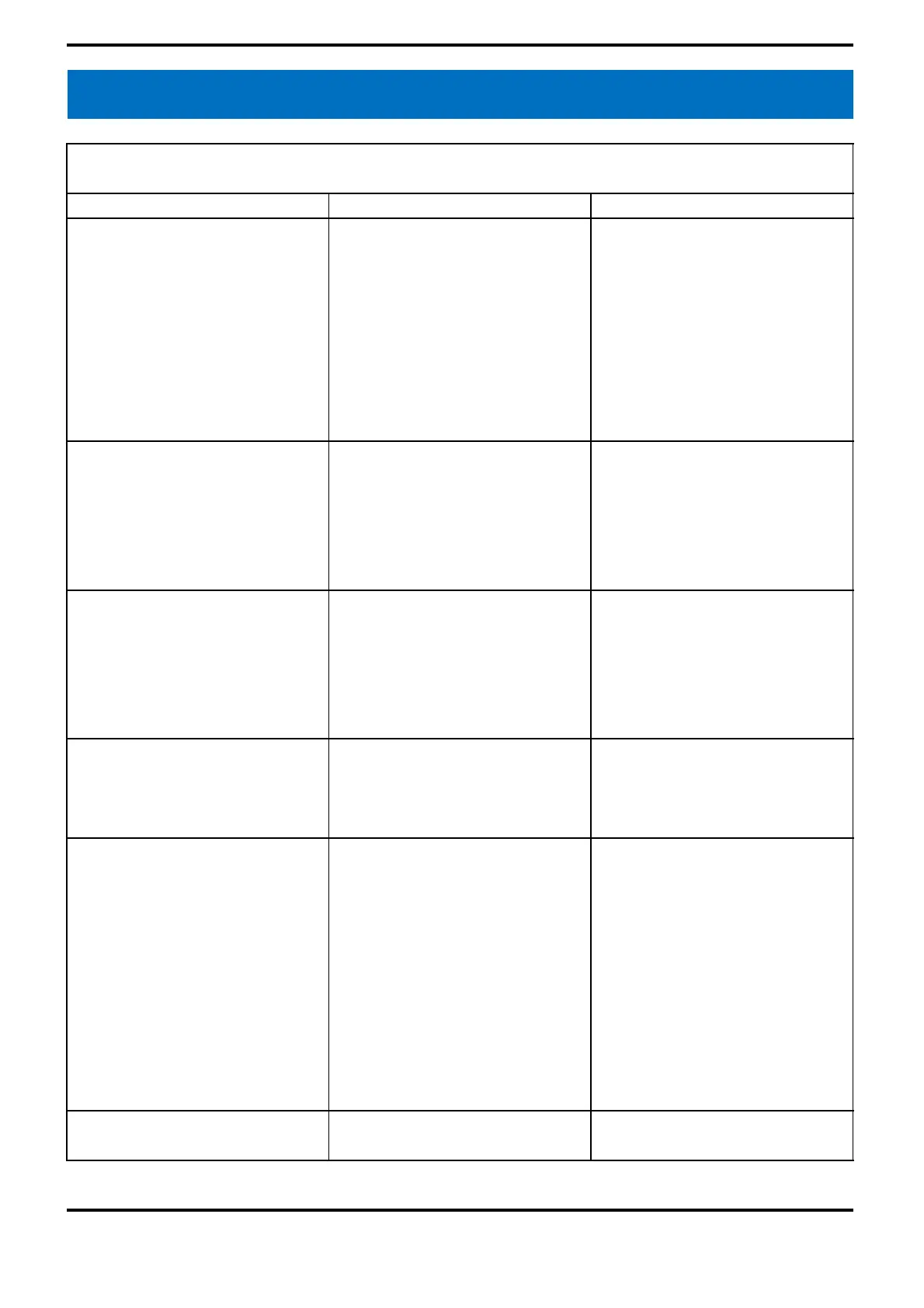

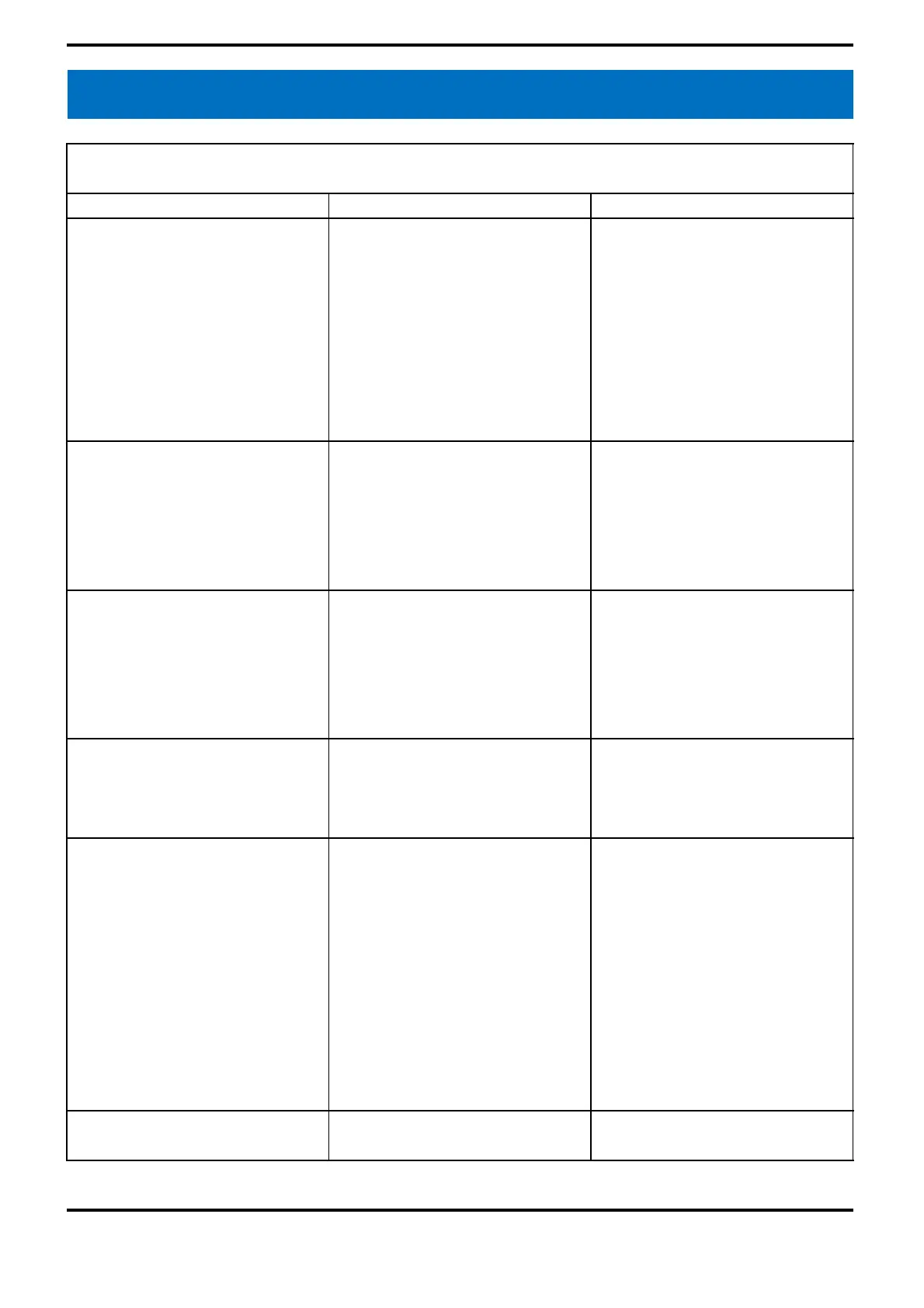

b) Inverter Unit or safety interlocks

‘tripped’

b) Check Inverter.

b) Inverter Unit or safety interlocks

‘tripped’

b) Inspect, clean/replace balls/seats

a) Ball checks not seating correctly.

c) Ball checks not seating correctly.

b) Worn piston seals

a) Air entering the suction

hose/manifold

e) Worn piston seals

d) Cam direction incorrect

c) Cam follower worn

b) Main shaft bearings worn

a) Replace piston seals.

c) Inspect, clean/replace balls/seats

b) Replace piston seals.

a) Check o-rings and hose

connections

Replace bellows seal, check piston

seal, replace as necessary

Paint leaking from inside cover Bellows seal failure

Pump will not run

a) Worn piston seals

a) No power a) Check electrical supply

Fault finding

Fluid Section

Symptom Possible Cause Remedy

Pump will not ‘Prime’

Pump runs, but lack of pressure

Excessive Pressure Pulsation

Replace bellows seal, check piston

seal, replace as necessary

Replace Bellows.Failed BellowPaint seen in leak detection hose.

77-3330 R1.3 31/36 www.carlisleft.com

Loading...

Loading...