2

Only qualified, authorized, and appropriately trained HVAC or re-

frigeration personnel should install, commission, and maintain this

equipment.

Use appropriate personal safety equipment where required. Safety

goggles, gloves, protective clothing, safety boots, and hardhats

should be worn where necessary.

OPERATING LIMITS

Operating envelopes of the compressor models will differ with

each model and refrigerant. These operating envelopes are

provided in the CARWIN rating program. See the Variable Speed

Supplemental Instructions (574-087) on the Carlyle website for

details.

GENERAL INSTALLATION PROCEDURES

Holding Charge

The 06CC compressor is factory-supplied with a 5 to 15 psig (1.4

to 2 bar) charge of dry air. This internal pressure must be relieved

before attempting to remove any compressor fitting or part.

Relieve holding charge by removing the cap on the low pressure

connection fitting and depressing the internal disc. See Fig. 1 for

applicable low pressure connection fitting location.

System Cleanliness and Dehydration

Clean and dry systems are essential for long compressor and mo-

tor life and satisfactory operation. Compressor lubricants require

special attention; excessive moisture, when combined with heat

and refrigerant, can form damaging acids. The recommended limit

for moisture is less than 50 ppm for compressors lubricated with

mineral oil (MO) or alkylbenzene (AB) lubricants and 100 ppm

for POE lubricants.

Use only piping which is clean and dry inside, free from rust and

process oils.

Suction Screen

All 06CC compressors are equipped with a suction strainer

located on the compressor side of the suction service valve. Verify

that the suction screen is installed. A second screen is factory-

installed in the midstage piping at the motor end to protect the mo-

tor and second stage cylinders. Do not operate the compressor

without both strainers installed.

Service Valves

Remove valve pads and attach factory-supplied suction and dis-

charge gaskets and service valves to the compressor. Torque appli-

cable service valve mounting bolts as noted in Table 6 on page 8.

When brazing piping to valve, disassemble valve or wrap in a wet

cloth to prevent heat damage.

Approved Refrigerants

The 06CC compressor is approved for the following refrigerants;

R-22, R-134a, R-404A, R-407A, R-407C, R-407F, R-448A,

R-449A, R-507A, and R-513A.

Oil

1. Check to see that oil level is 1/8 to 3/8 of the way up on com-

pressor sightglass (see Table 2) before starting and after

15 to 20 minutes of operation. Compressors may be shipped

with or without an oil charge based on model. All compres-

sors must contain the specified oil charge prior to start up as a

condition of warranty.

2. To add oil:

Isolate crankcase and reclaim internal pressure, and add oil

through the oil fill connection (see Fig. 1).

To remove excess oil:

Reduce internal crankcase pressure to 2 psig (1.15 bar), iso-

late crankcase then loosen the oil drain plug allowing oil to

seep out past the threads of the plug.

3. When additional oil or a complete oil change is required, use

only the listed Carlyle approved oils as shown in Table 3.

Scan QR code for link to Carlyle literature website

http://bit.ly/47z3SP7

CAUTION

Oil levels on 06CC 50-99 cfm compressors should not be al-

lowed to go above 3/8 of sightglass. High oil levels require ex-

cess power and shorten compressor life. See Table 2.

CAUTION

Do not charge oil through the suction line or through the com-

pressor suction access fittings. See Fig. 1 for the recommended

oil charging port. Adding oil into the suction side of the

compressor can cause damage to the suction/discharge valves,

pistons, and/or connecting rods.

CAUTION

With the compressor crankcase under slight pressure, do not

remove the oil drain plug as the entire oil charge could be lost.

Do not reuse drained oil or oil that has been exposed to the at-

mosphere.

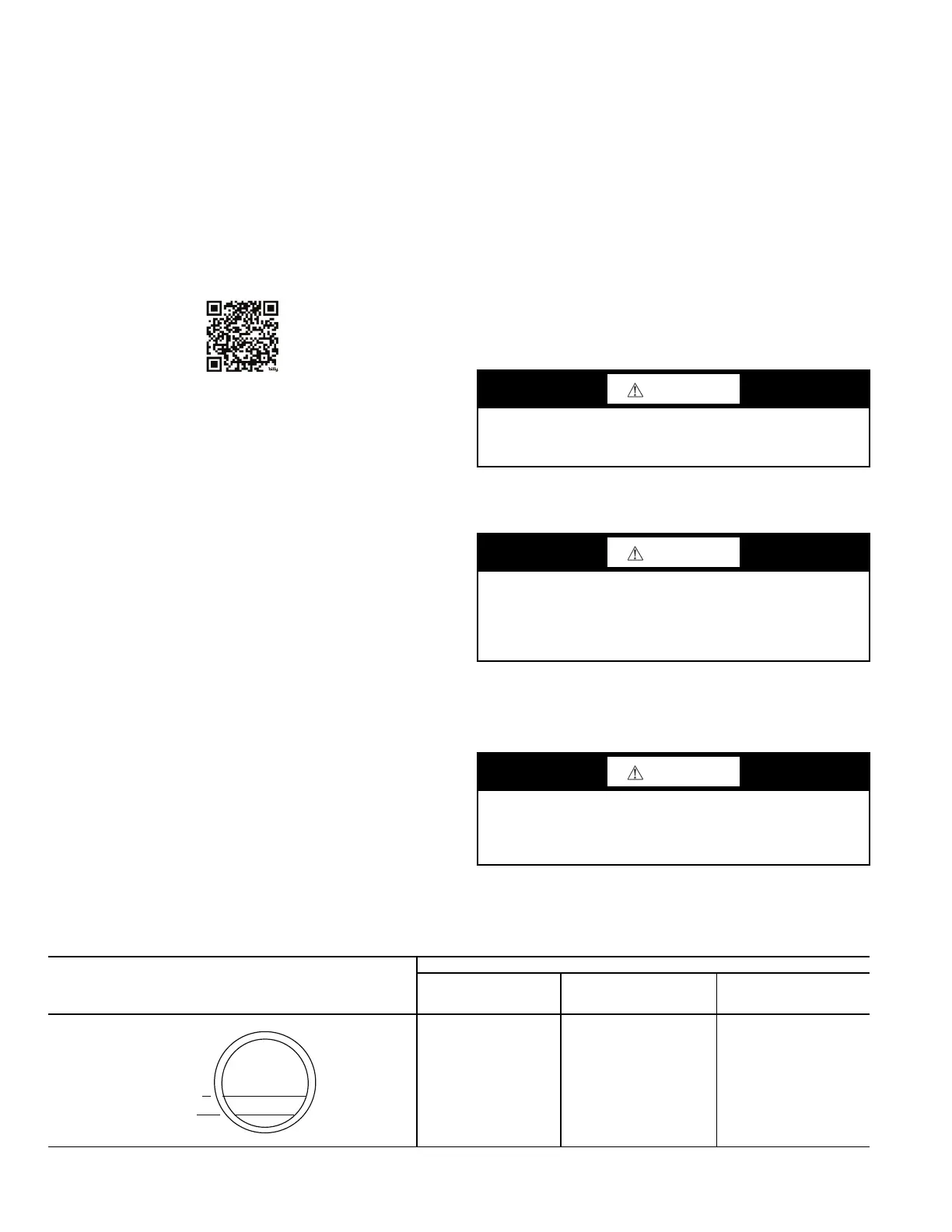

Table 2 — 06CC 50-99 cfm Sightglass

06CC 50-99 cfm OILSIGHTGLASS LEVEL

NOMINAL OIL CHARGE

NEW SYSTEM

(DRY PIPING)

Pints (Liters)

COMPRESSOR

EXISTING SYSTEM

(WET PIPING)

Pints (Liters)

21.0 (9.9) 50, 65, 75, 99 cfm 19.0 (9.0)

Loading...

Loading...