4

ELECTRICAL

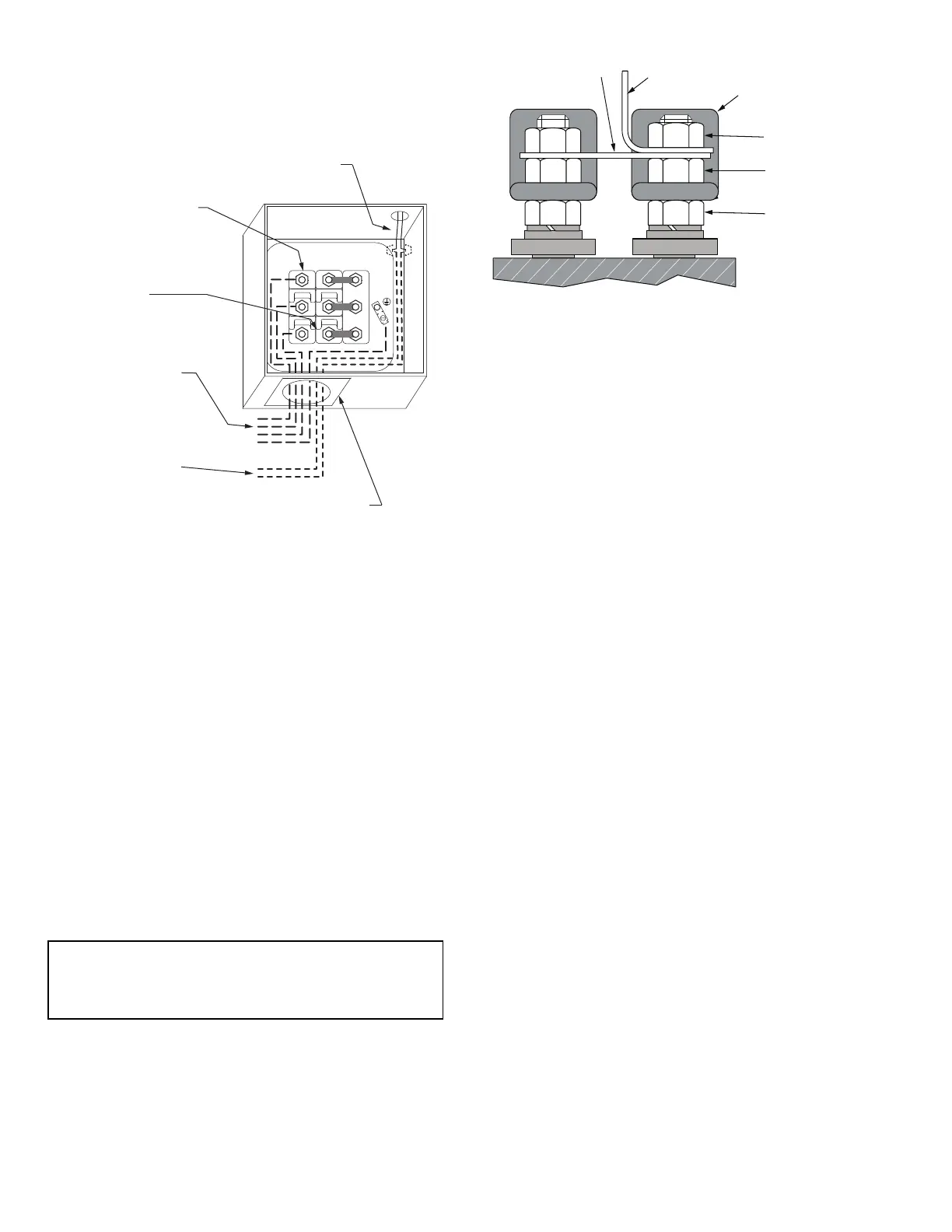

For proper wiring connections, consult the wiring diagram located

inside the compressor terminal box cover and Fig. 2 for wiring

connection locations. Refer to Fig. 2-4 for terminal plate

components.

Fig. 2 — Terminal Box Arrangement

Terminal Box

All UL recognized 06CC compressors have terminal enclosures

that are suitable for outdoor use equipment as a sole enclosure.

The compressor terminal box is supplied with a support plate to

mount the connector for the power wiring conduit. The support

plate can be fastened to the terminal box with the (4) screws pro-

vided.

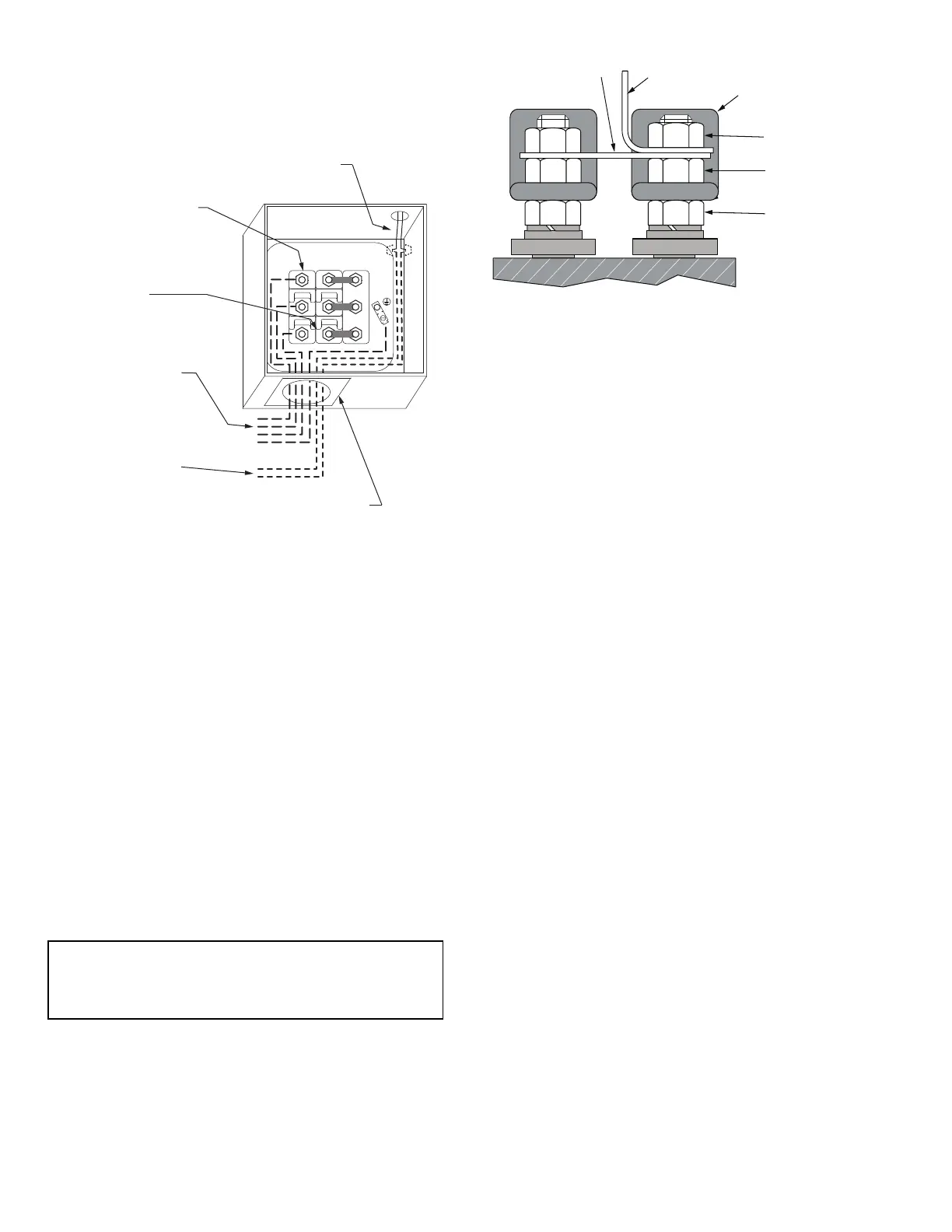

Terminal Plate Wiring

The parts listed in Table 1 are supplied in a parts bag with the

compressor and are used when wiring the terminal plate. Refer to

Step 4 in the General section on page 1 and Table 1. Customer

supplied wiring to the compressor terminal plate must be provided

with insulated wire terminal connectors and be suitable for accom-

modating the 3/8 in. diameter terminal studs. Figure 3 shows the

wiring components of the terminal plate. Jam Nut No. 1 is factory-

installed and should not be disturbed. Jam Nut No. 2 should be in

contact with the underside of the jumper bar or ring terminal if no

jumper bars are used. Jam Nut No. 2 should be installed finger

tight, never torqued with a wrench. Jam Nut No. 3 should be in

contact with the upper side of the jumper bars or ring terminal and

should be wrench torqued.

Fig. 3 — Terminal Plate Components

6-PIN TERMINAL PLATE3-LEADACROSS-THE-LINE (XL)

START

See Fig. 4A.

6-PIN TERMINAL PLATE3-LEADVARIABLE SPEED

See Fig. 4G.

Install (3) 2-hole copper jumper bars directly on top of Jam Nut

No. 2, connecting terminals T

1

to T

7

, T

2

to T

8

, and T

3

to T

9

.

1. Connect the line leads directly on top of the jumper bars to

terminals T

1,

T

2

, and T

3

.

2. Install (6) Jam Nut No. 3 (included in this kit) on terminal

studs to secure jumper bar/line connections. Tighten Jam Nut

No. 3 to 18 lb-ft (24 Nm) maximum.

6-PIN TERMINAL PLATE6-LEADACROSS-THE-LINE (XL)

START

Not shown in Fig. 4.

1. Install (3) 2-hole copper jumper bars directly on top of Jam

Nut No. 2, connecting terminals T

1

to T

7

, T

2

to T

8

, and T

3

to

T

9

.

2. Connect the line leads directly on top of the jumper bars to

terminals T

1

, T

2

, T

3

, T

7

, T

8

, and T

9

.

3. Install (6) Jam Nut No. 3 (included in this kit) on terminal

studs to secure jumper bar/line connections. Tighten Jam Nut

No. 3 to 18 lb-ft (24 Nm) maximum.

6-PIN TERMINAL PLATE6-LEADPART WINDING (PW)

START

See Fig. 4D.

1. Jumper bars are not required with 6-Lead PW start applica-

tions. Jam Nut No. 2 should be finger tightened only, do not

torque with wrenches.

2. Connect the part winding start leads directly on top of Jam

Nut No. 2 to terminals T

1

, T

2

, and T

3

.

3. Connect the full winding run leads directly on top of Jam Nut

No. 2 to terminals T

7

, T

8

, and T

9

.

4. Install (6) Jam Nut No. 3 (included in this kit) on terminal

studs to secure jumper bar/line connections. Tighten Jam Nut

No. 3 to 18 lb-ft (24 Nm) maximum.

IMPORTANT: Variable speed applications should refer to

the Variable Speed Compressor Supplemental, 574-087 for

electrical details that are specific to variable speed applica-

tions

Factory-Supplied Wiring To

Cylinder Head Temp Sensor

3/8 in.-16 Terminal Studs

For Motor Connections

(T

4

T

5

and T

6

are present only

in the 9-pin terminal plate.)

Customer Supplied

Wiring To Motor

Connections

Jumper Bars

(See wiring diagrams for

configuration details.)

Customer Supplied

Wiring To Sensor

Connections

Factory-Supplied

Adapter Plate For

Conduit Connection

1 7

2 8

3 9

4

5

6

1

2

3

1

2

3

Jam Nut No. 1

Jam Nut No. 3

Jam Nut No. 2

Ring Terminal

Jumper Bar

Insulator

NOTE: Jumper bars not required in all installations. Refer to Fig. 5

for usage.

Loading...

Loading...