3

LEGEND

Pressure Relief Valve

A sufficient number of pressure relieving devices and/or

pressure relief valves, having capacity deemed adequate for the

system, may need to be provided. They must be located such that

no stop valve is located between the relief valve and the section

of the system being protected. The maximum allowable pressure

for the high side of the 06CC 50-99 cfm compressors is

464.7 psia (32.0 bar) and for the low side is 299.7 psia (20.6 bar).

The 06CC 50-99 cfm compressors have two factory-installed in-

ternal pressure relief valves. The first relief valve is located in the

valve plate and will start-to-discharge at a differential pressure

(interstage to suction) of 200 psid (13.8 bar), ±10%. Once this

valve has relieved at the specified pressure, it should remain ful-

ly functional, but it may relieve at a lower pressure. If this pres-

sure goes below 3% of its set point (175 psid, 12.0 bar), then the

valve should be replaced.

The second relief valve is located in the crankcase body under

the center head valve plate and will start-to-discharge at a differ-

ential pressure (discharge to midstage) of 400 psid (27.6 bar),

±3%. Once this valve has relieved at the specified pressure, it

should remain fully functional, but it may relieve at a lower pres-

sure. If this pressure goes below 10% of its set point (349 psid,

24.1 bar), then the valve should be replaced.

Connection Points

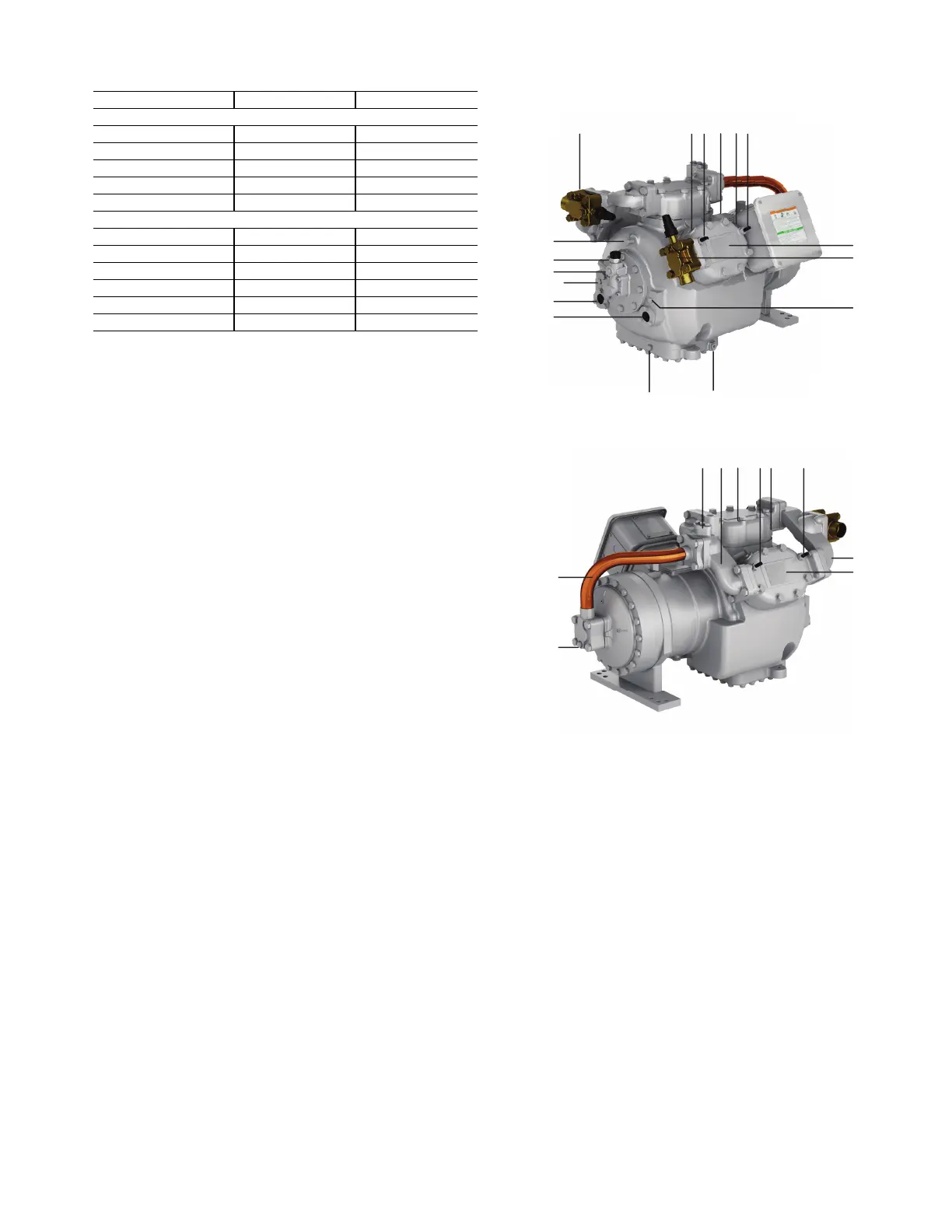

Fig. 1 — 06CC 50-99 cfm Compressor (Pump End)

Table 3 — Approved Oils

MANUFACTURER OIL TYPE BRAND NAME

For HFC Refrigerants

Totaline POE P903-1701

Castrol POE E68

ICI Emkarate POE RL68H

Lubrizol Lubrikuhl POE 2916S

Texaco Capella POE HFC 68NA

For HCFC and CFC Refrigerants

Totaline MO P903-0101

Witco Suniso MO 3GS

IGI Petroleum MO Cryol150

Texaco Capella MO WFI32-150

Totaline AB P903-2001

Shrieve Chemicals AB Zerol150

AB — Alkybenzene Oil

MO — Mineral Oil

POE — Polyolester-Based Oil

A E

C

U

J, L

B

F

G

H

J, L

K

K

M N

06CC, 2-stage, 50-99 cfm

T

V

T

W S D SY

W

X

SR S

A

B

C

D

E

F

G

H

J

K

L

M

N

R

S

T

U

V

W

X

Y

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

—

Nameplate Location

Suction Service Valve

Discharge Service Valve

Low Pressure Connection

High Pressure Connection

Interstage Pressure Connection

Oil Pressure Mechanical Sensor

Oil Pressure Connection

Low Side Oil Pressure Difference

Oil Level Sightglass

Oil Sump Fill Port

Oil Sump Drain Port

Crankcase Heater

Discharge Gas Temperature Sensor

Cylinder Head Fan Studs

1st Stage Cylinder Head

2nd Stage Cylinder Head

Suction Manifold

Interstage Manifold

Desuperheating Liquid Injection

Vapor Injection Flange

LEGEND

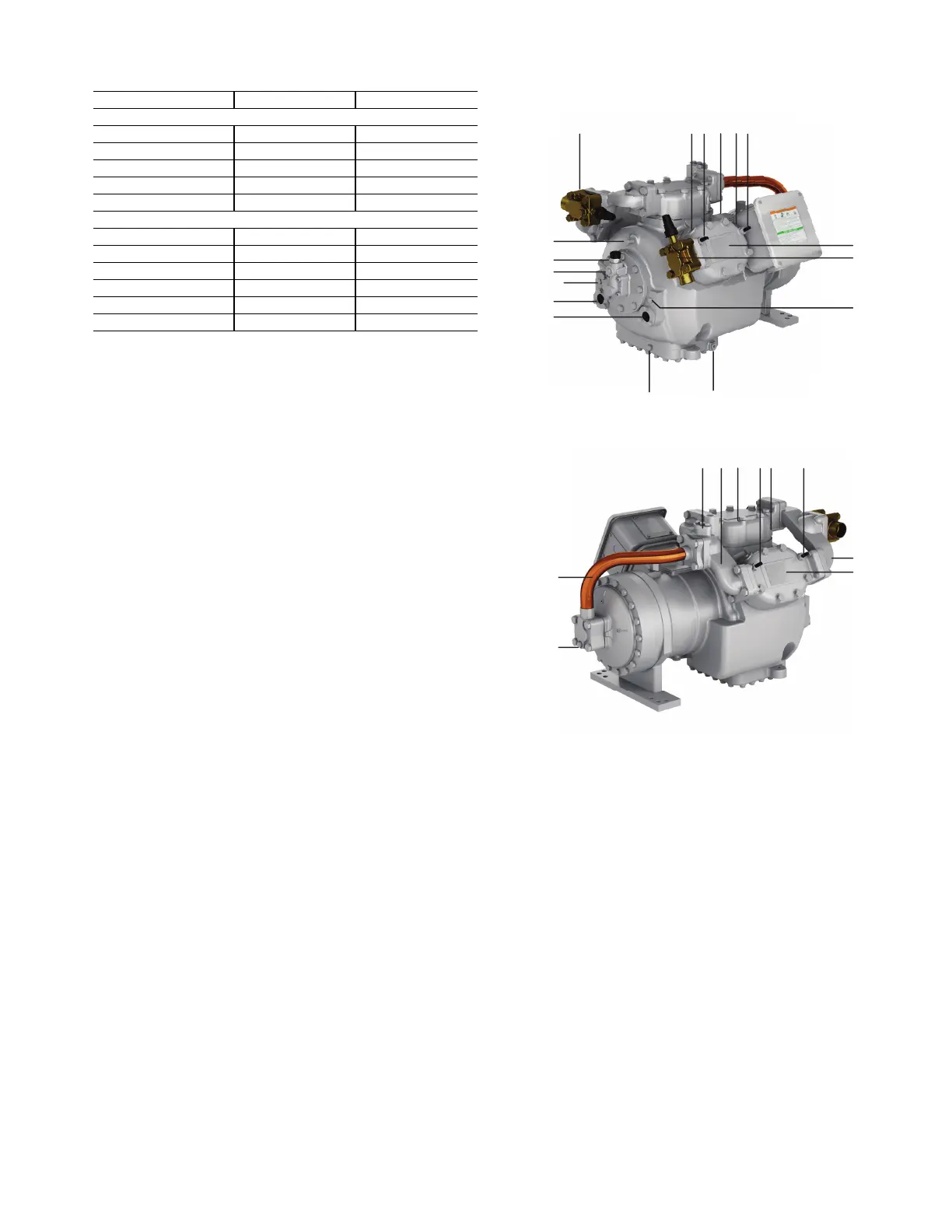

Motor End

Pump End

Loading...

Loading...