5

9-PIN TERMINAL PLATE ACROSS-THE LINE (XL)

START208/230V-3-60/200V-3-50

See Fig. 4B.

9-PIN TERMINAL PLATE VARIABLE SPEED

208/230V-3-60/200V-3-50

See Fig. 4H.

1. Remove plastic connector block from terminals T

4

, T

5

,

and T

6

.

2. Install the flat connector block (non-conducting) on

terminals T

4

, T

5

, and T

6

.

3. Reinstall Jam Nut No. 2 on terminals T

4

, T

5

, and T

6

(removed in Step 2). Finger tighten only; do not torque with

wrenches.

4. Install the 3-hole copper jumper bar directly on top of Jam

Nut No. 2, connecting terminals T

4

, T

5

, and T

6

.

5. Install (3) 2-hole copper jumper bars directly on top of Jam

Nut No. 2, connecting terminals T

1

to T

7

, T

2

to T

8

, and T

3

to T

9

.

6. Connect the line leads directly on top of the jumper bars to

terminals T

1

, T

2

, and T

3

.

7. Install (9) Jam Nut No. 3 (included in this kit) on terminal

studs to secure jumper bar/line connections. Tighten Jam

Nut No. 3 to 18 lb-ft (24 Nm) maximum.

9-PIN TERMINAL PLATEPART WINDING (PW) START

208/230V-3-60/200V-3-50

See Fig. 4E.

1. Remove plastic connector block from terminals T

4

, T

5

,

and T

6

.

2. Install the flat connector block (non-conducting) on termi-

nals T

4

, T

5

, and T

6

.

3. Re-install terminal nuts on terminals T

4

, T

5

, and T

6

(removed in Step 1). Finger tighten only, do not torque with

wrenches.

4. Install the 3-hole copper jumper bar directly on top of Jam

Nut No. 2, connecting terminals T

4

, T

5

, and T

6

.

5. Connect the line leads directly on top of the jumper bars to

terminals T

1

, T

2

, T

3

, T

7

, T

8

, and T

9

.

6. Install (9) Jam Nut No. 3 (included in this kit) on terminal

studs to secure jumper bar/line connections. Tighten Jam

Nut No. 3 to 18 lb-ft (24 Nm) maximum.

9-PIN TERMINAL PLATE ACROSS-THE LINE (XL)

START460V-3-60/400V-3-50

See Fig. 4C.

9-PIN TERMINAL PLATEVARIABLE SPEED460V-3-60/

400V-3-50

See Fig. 4I.

1. Install (3) 2-hole copper jumper bars connecting terminals

T

7

to T

4

, T

8

to T

5

, and T

9

to T

6

.

2. Connect the line leads directly on top of the jumper bars to

terminals T

1

, T

2

, and T

3

.

3. Install (9) Jam Nut No. 3 (included in this kit) on terminal

studs to secure jumper bar/line connections. Tighten Jam

Nut No. 3 to 18 lb-ft (24 Nm) maximum.

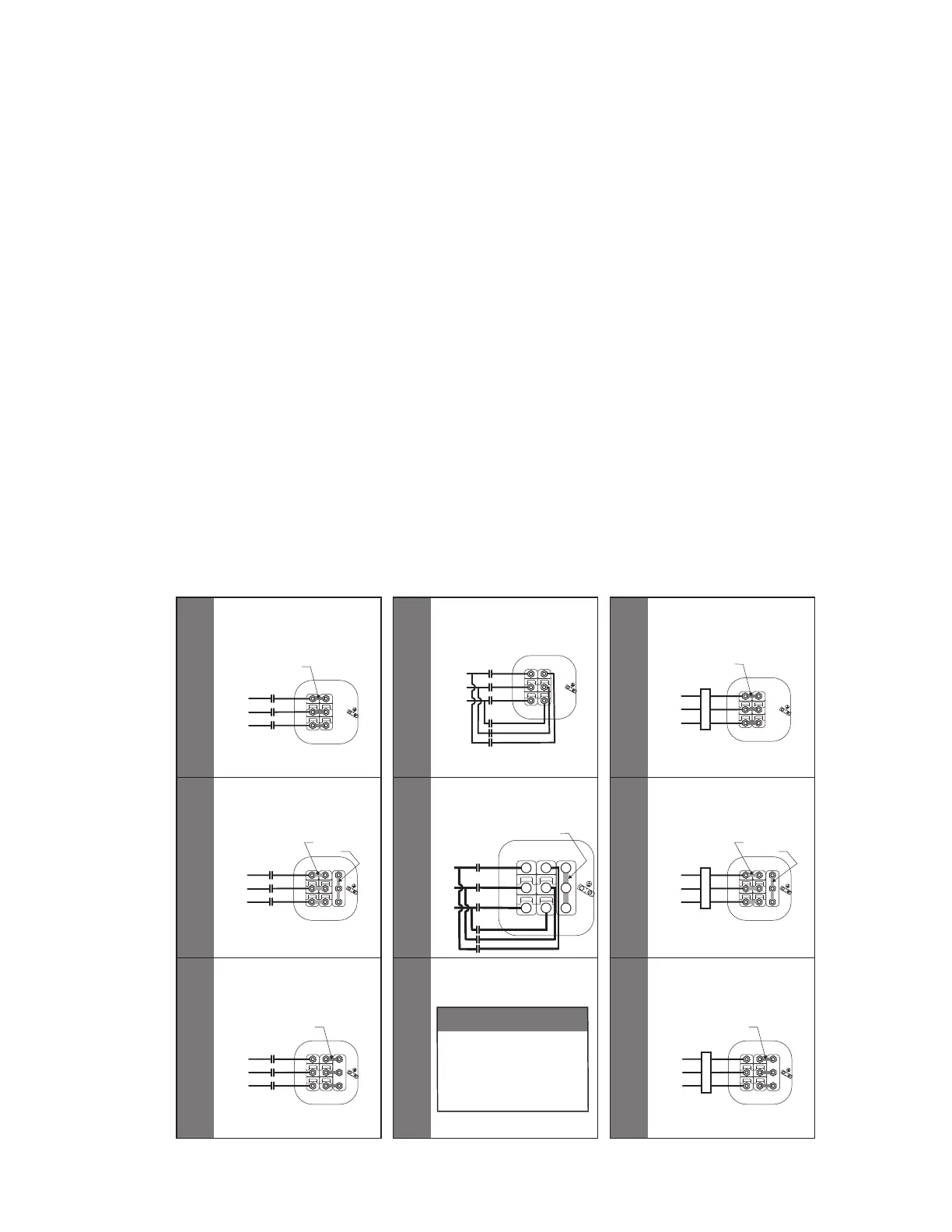

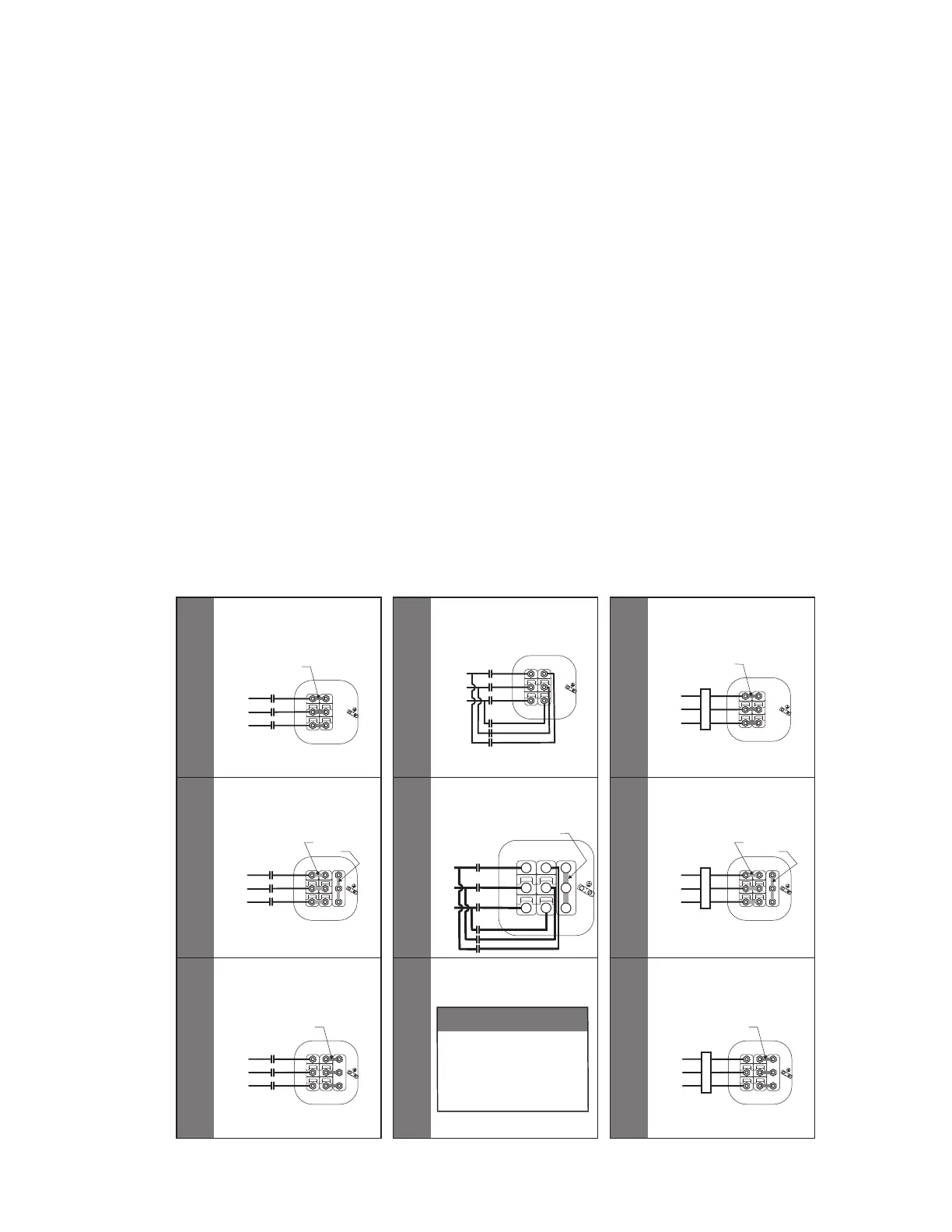

Fig. 4 — Terminal Plate Wiring Schematic

6-PIN TERM PLATE

DISCRETE VOLTAGE

3-LEAD XL START

A

9-PIN TERM PLATE

208/230/460V DUAL VOLTAGE

208/230V 3-LEAD XL START

B

L1

L2

L3

JUMPER BARS

(2 HOLE)

9-PIN TERM PLATE

208/230/460V DUAL VOLTAGE

460V 3-LEAD XL START

C

6-PIN TERM PLATE

DISCRETE VOLTAGE

6-LEAD PW START

D

9-PIN TERM PLATE

208/230/460V DUAL VOLTAGE

208/230V PW START

E

9-PIN TERM PLATE

208/230/460V DUAL VOLTAGE

460V PW START

F

WARNING

208/230/460V MODELS

CANNOT BE WIRED FOR

460V PART WIND START.

USE DISCRETE 460V MOTORS

FOR ANY 460V PART WIND

APPLICATIONS.

6-PIN TERM PLATE

3-LEAD VARIABLE SPEED

460V, 575V

G

9-PIN TERM PLATE

3-LEAD VARIABLE SPEED

208/230V

H

9-PIN TERM PLATE

3-LEAD VARIABLE SPEED

460V

I

1 7

2 8

3 9

4

5

6

L1

L2

L3

JUMPER BARS

(2 HOLE)

1 7

2 8

3 9

4

5

6

VFD

L1

L2

L3

Jumper Bars

(2 Hole)

1 7

2 8

3 9

L1

L2

L3

JUMPER BARS

(2 HOLE)

1 7

2 8

3 9

VFD

L1

L2

L3

1 7

2 8

3 9

1 7

2 8

3 9

4

5

6

L1

L2

L3

JUMPER BAR

(3 HOLE)

4

5

6

L1

L2

L3

JUMPER BARS

(2 HOLE)

(3 Hole)

71

82

3 9

4

5

6

L1

L2

L3

JUMPER BARS

(2 HOLE)

(3 HOLE)

71

82

3 9

VFD

Loading...

Loading...