15

The oil cooler does offer some help in keeping

the discharge and motor temperatures within

their respective limits. To make up for this lost

cooling some additional refrigerant injection is

required. For screw compressors this injection

is by the motor cooling valve or at the rotor

injection port. Because refrigerant injection for

motor and discharge cooling flows into the

screw rotor chamber after the suction gas is

trapped, compressor capacity is not affected

significantly. Under some conditions the motor

cooling valve can accommodate this extra

cooling requirement. For conditions requiring

additional injection, a Sporlan Y-1037 desuper-

heating valve, or its equivalent, is recommend-

ed. It should be selected to start opening at a

discharge temperature of 190 F and be fully

open at 200 F. The bulb should be located on

the discharge line within 6" of the compressor

discharge service valve. A properly sized sole-

noid valve should be located upstream to

insure positive shut-off when the compressor is

off.

The tables presented at the bottom of this

page present desuperheating size and part

number information for those applications

where an oil cooler is not used.

Even when an oil cooler is used, desuperheat-

ing may still be required. For R-22 systems,

the desuperheating valve is required when

the saturated suction temperature is below

-25°F (-32°C) and for R-404A/R-507 systems,

it is necessary when the saturated suction

temperature is below -40°F (-32°C). This valve

is available through Carlyle (1 ton (3.5Kw);

1.5 ton (5.3Kw); contact Carlyle Application

Engineering for valve selection).

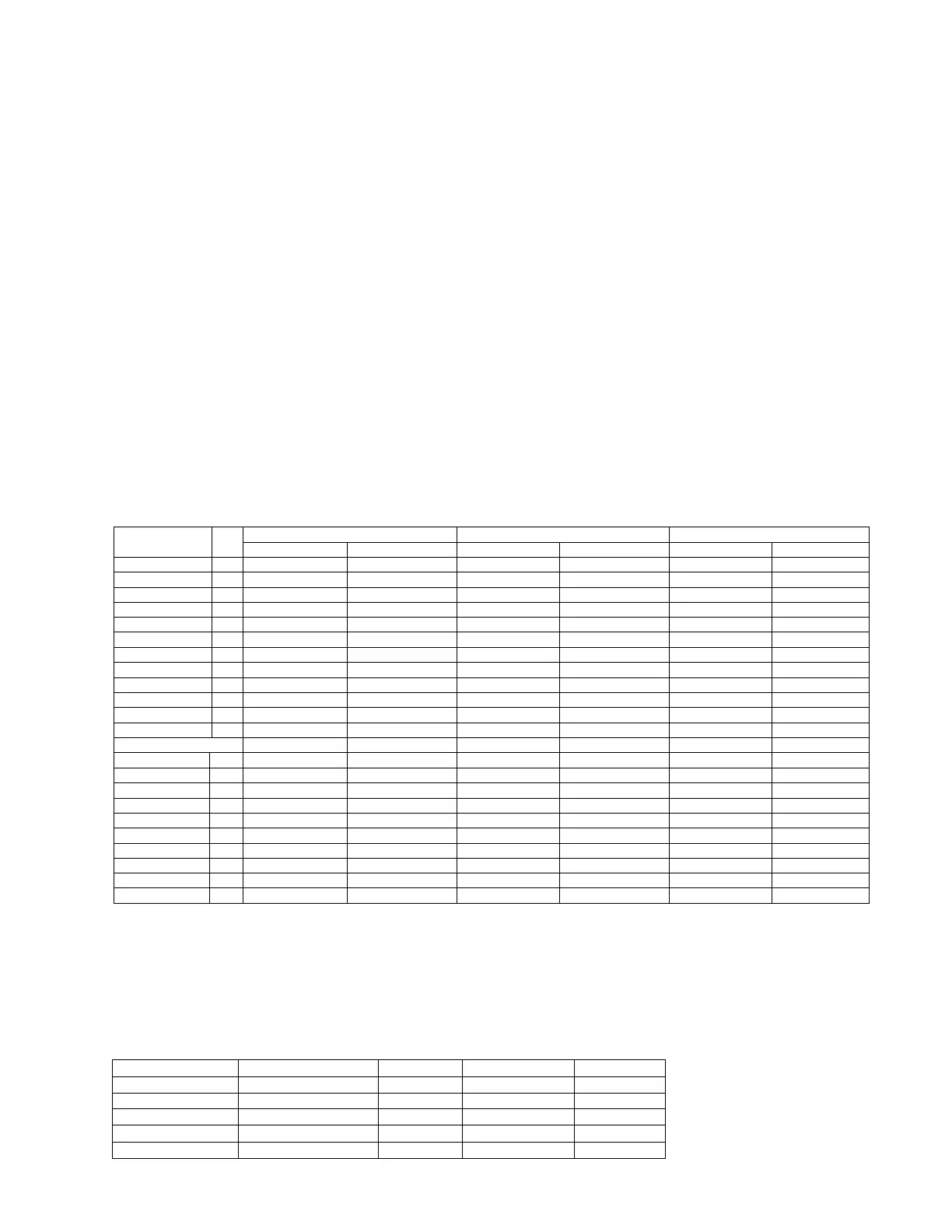

DESUPERHEATING VALVE SIZING WITHOUT OIL COOLER

R-22 Added Desuperheating R-404A/507 Added Desuperheating R134a Added Desuperheating

Compressor

Model

HP

Low Temp. Med/High Temp. Low Temp. Medium Temp. Medium Temp. High Temp.

Low Temp.

SCT Range 70 to 120 F 90 to 120 F 70 to 150 F 70 to 150 F

(21 to 49 C) (32 to 49 C) (21 to 65 C) (21 to 65 C)

06TRC033 15 FV-2 N/A FV-1* N/A None None

06TRD039 20 FV-3 N/A FV-1-1/2* N/A None None

06TRD044 20 FV-3 N/A FV-1-1/2* N/A None None

06TRE048 25 FV-3 N/A FV-2* N/A None None

06TRE054 25 FV-3 N/A FV-3* N/A None None

06TRF065 30 FV-5 N/A FV-3* N/A None None

06TRG078 35 FV-5 N/A FV-3* N/A None None

06TRH088 40 FV-5 N/A FV-3* N/A None None

06TRK108 50 FV-5 N/A FV-3* N/A None None

Med Temp/High Temp

SCT Range 70 to 130 F 70 to 130 F

(21 to 54 C) (21 to 34 C)

06TAD033 20 N/A FV-2** N/A None None None

06TAE039 25 N/A FV-3** N/A None None None

06TAF044 30 N/A FV-3** N/A None None None

06TAF048 30 N/A FV-3** N/A None None None

06TAG054 35 N/A FV-3** N/A None None None

06TAG065 35 N/A FV-5** N/A None None None

06TAH078 40 N/A FV-5** N/A None None None

06TAK088 50 N/A FV-5** N/A None None None

LEGEND

* Operation with Evap condensers below -25 F SST may not require any additional desuperheating.

Contact Carlyle Applicatioon Engineering for limits.

** Operation with Evap condensers above +10F SST may not require any additional desuperheating.

Contact Carlyle Application Engineering for limits.

Note: Valve P/N's shown above are for Sportan Valve Y-1037 series desuperheating valves. A valve with a 190 F temperature setting is required. Alternate

desuperheating valve sizing or manufacturers must be approved by Carlyle Application Engineering.

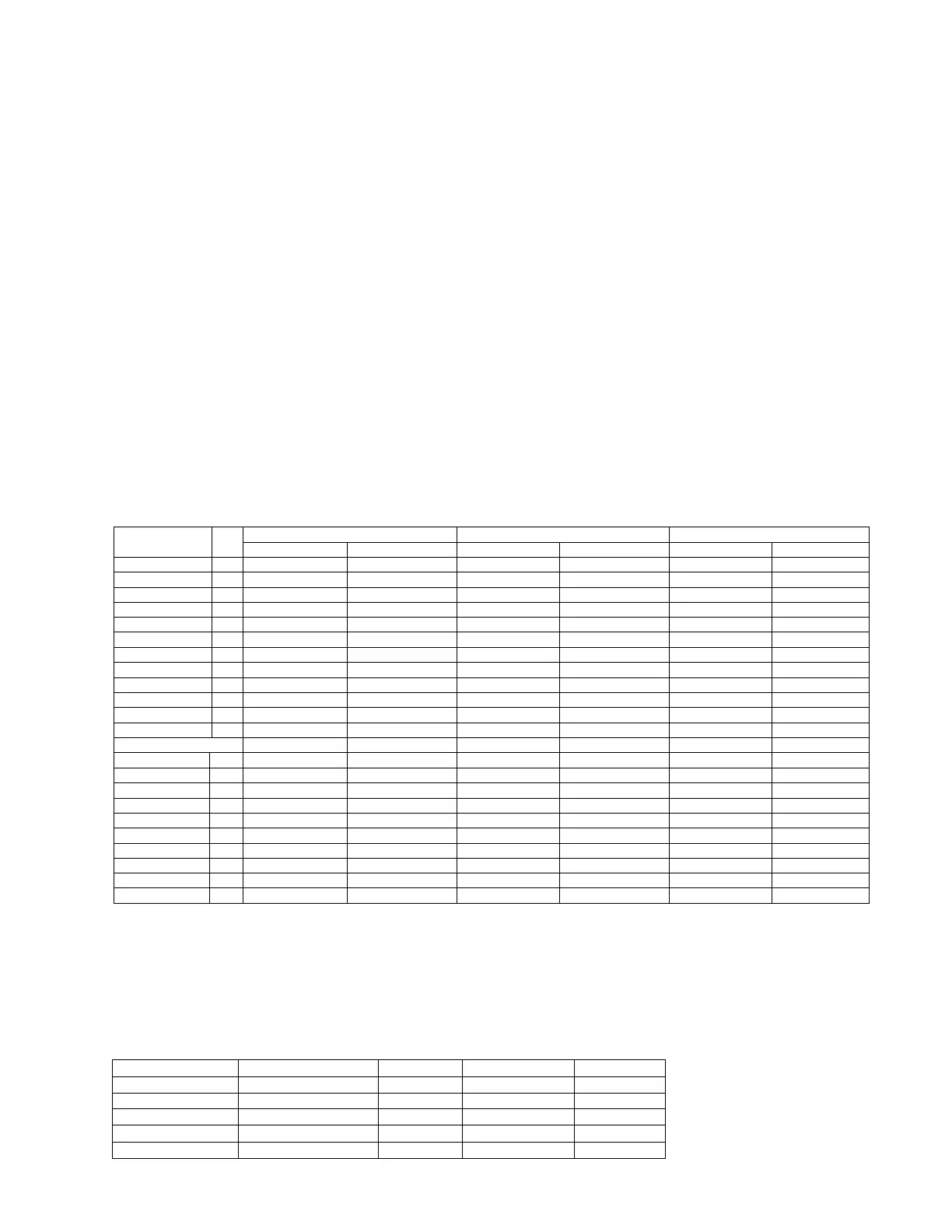

Sporlan Part No. Carlyle Part No. Qty./Pkg. Weight (Lbs.) Size

FV-1 EA02ZD001 1 2 1 ton

FV-1-1/2 EA02ZD002 1 2 1-1/2 ton

FV-2 EA02ZD030 1 2 2 ton

FV-3 EA02ZD050 1 2 3 ton

FV-5 EA02ZD100 1 2 5 ton

Loading...

Loading...