48

The water connections on the desuperheater water inlets and

outlets must not cause any mechanical local constraint at the

heat exchangers. If necessary, install exible connection sleeves.

Install water ow control and balancing valves at the heat

exchanger outlet.

The volume of the desuperheater circuit water loop must be

as low as possible so that the temperature can increase rapidly

when the unit is started up.

The minimum entering water temperature at the desuper-

heater is 25°C. This requires the use of a three-way valve (item

31 in the diagram), with a controller and the sensor controlling

the minimum required entering water temperature.

The desuperheater water loop must include a relief valve and

an expansion tank. When selecting these, consider the water

loop volume and the maximum temperature (90°C) when

pump operation is stopped (item 20 in the diagram).

option

The unit can operate in two modes.

18.4.1 - Efciency priority mode (standard)

In this mode unit control optimises unit efciency. Heat

reclaim is based on the saturated condensing temperature.

The percentage of the reclaimed heating capacity compared

with the total capacity rejected by the condenser increases

in proportion to the saturated condensing temperature. This

temperature is directly linked to the condenser entering air

temperature (entering air temperature in cooling mode and

water temperature in heating mode).

18.4.2 - Reclaim priority mode

In cooling mode only this conguration allows the user to

enter a setpoint that is relative to the minimum condensing

temperature (default = 40°C) to increase the heating capacity

reclaimed at the desuperheaters, if required. This conguration

is only effective if the desuperheater contact is activated on

the control board (user connection block). This function is not

available for 30RQSY units.

For setpoint control of the minimum saturated condensing

temperature and to nd the position of the connection block

on the board refer to the 30RB/RQ Touch Pilot Junior control

manual.

Other parameters directly affecting the effective capacity

reclaimed at the desuperheater are principally:

• The unit load rates, that decide whether the unit operates

at full load (100%) or part load.

• The water entering temperature in the desuperheater

as well as the condenser entering air temperature.

Entering water temperature at start-up °C 25* 60

Leaving water temperature during operation °C 30 65

Outside operating temperature °C -10 46

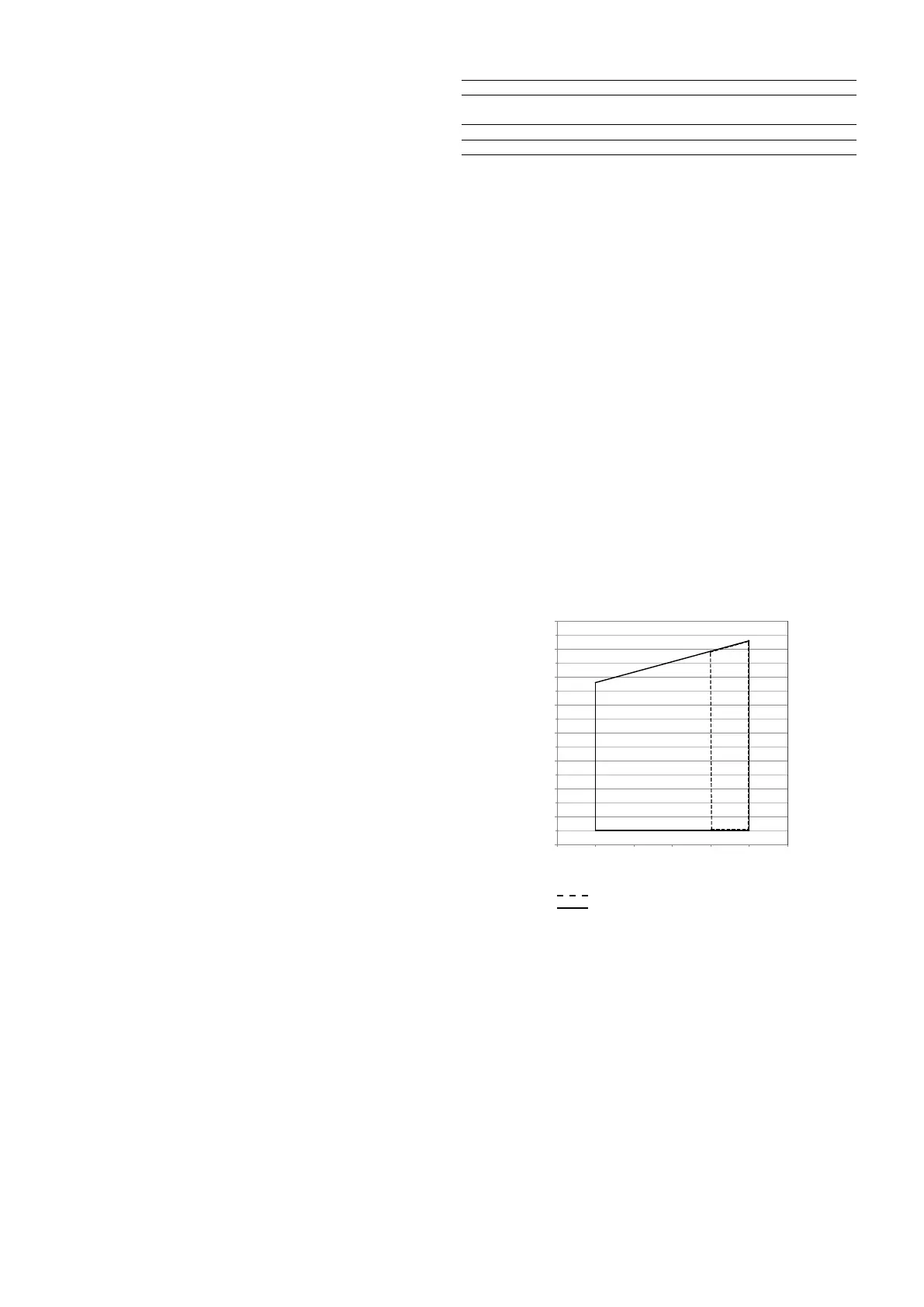

This option allows production of brine down to 0°C (option

5B) / -15°C (option 6B). The unit is equipped with suction

pipe insulation (option 6B only) and a fan frequency

converter.

The operating range is a function of the suction pressure,

which in turn is a function of:

- the brine type,

- the brine concentration,

- the ow rate,

- the brine temperature,

- the condensing pressure (ambient temperature).

Example: For operation with ethylene glycol at 45% and a

brine temperature of -15°C (entering temperature -10°C), the

maximum outside operating temperature will be around 33°C.

-25

-15

-5

5

15

25

35

45

55

-20-15-10-50510

Outside air temperature, °C

Evaporator leaving water temperature, °C

The evaporator low pressure and frost protection depends

on the amount of antifreeze added to the water circuit. The

evaporator approach (LWT - SST) as well as frost protection

are based on this amount).

It is therefore essential to control the amount of antifreeze

in the water loop at the rst start-up (circulate for 30 minutes

to ensure good homogeneity of the mixture before taking

the sample). Refer to the manufacturer’s data to dene the

frost protection, based on the concentration rate measured.

The frost protection temperature must be used in the unit

software parameters.

Option 5B

Option 6B

Loading...

Loading...