Controls

Low Energy Consumption Fan Motor

Electric heaters are controlled by “B”-type CARRIER control.

The electric heaters are equipped with two safety thermostats, one

with automatic reset, the second with manual reset, to protect the unit

against overtemperature that may happen in case of incorrect lter

cleaning or obstructions of the air ow.

NOTES:

In the size 15 unit with “HIGH -LOW POWER” heating element, the •

ULOW speed wire (RED MOTOR WIRE) must be disconnected and

insulated.

The LOW SPEED WIRE (YELLOW MOTOR WIRE) must be connected

in its place.

In case of failure in the electric fan, replace the electric heater too. •

Only qualied personnel should carry out this operation.

T-o access the control box panel, remove the screw located at the

bottom of the cover and delicately bend the tab to remove the cover.

Connect the power supply to the electric heater terminal. Size the

cables according to current drawn (see table III “Technical data of

electric heater).

It is important not to obstruct the supply or air ow and to

periodically check that the lter is clean.

NOTE:

The simultaneous use of hot water and electric heater is possible

in “ONLY LOW POWER” mode. Electric heaters and hot water can

not be used in high power mode. To operate the additional heating

function you need to buy the 42N9084 kit and connect the special

sensor as described in the installation manual. After this, the

corresponding dip switch no. 5 of the type B control must be set to

ON.

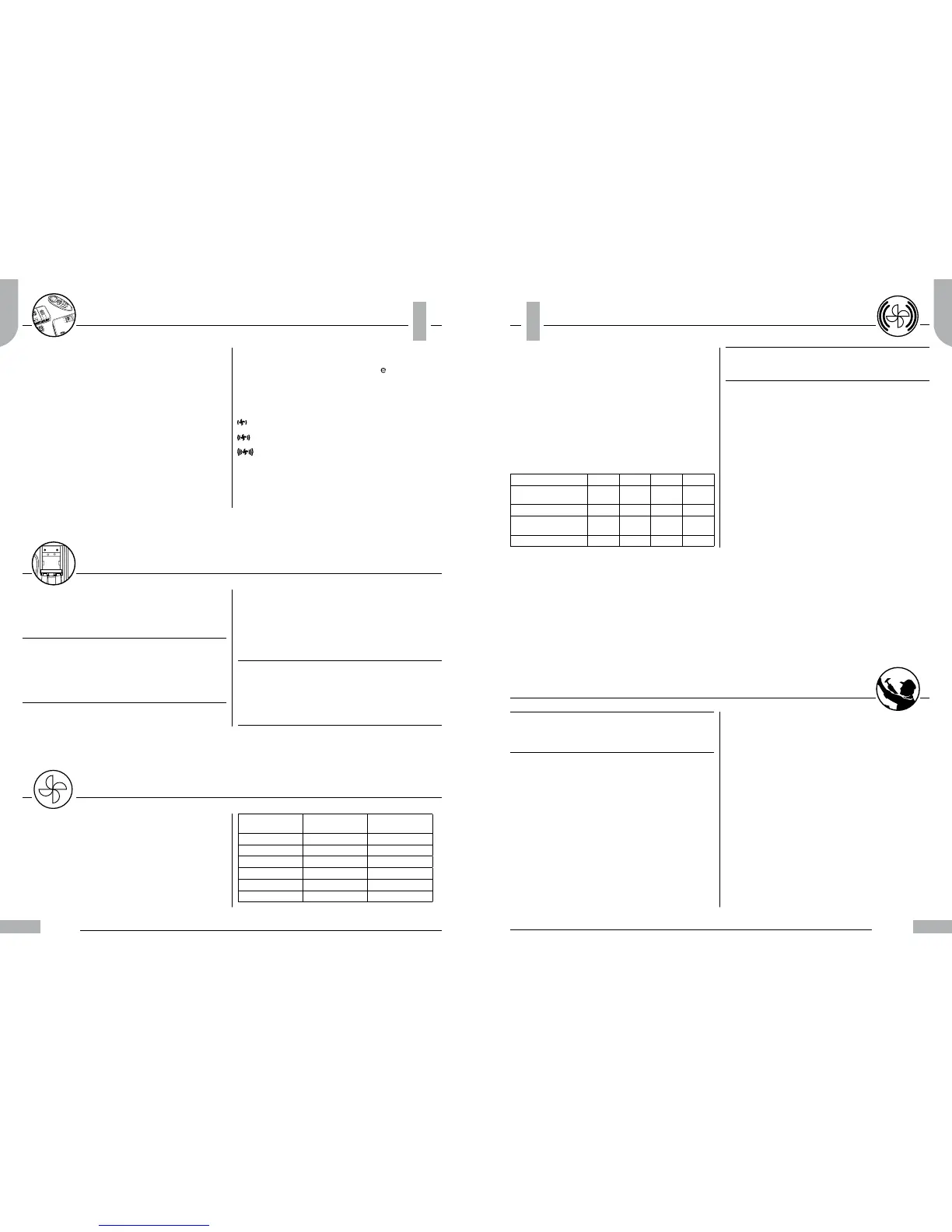

Fan Motor

The units have tangential/centrifugal motors with selectable speeds.

There are 5 speeds available:

Ultra Low- Low-Medium-High-Super High.

All machines are congured at the factory as follows:

ULTRA LOW - MEDIUM – SUPER HIGH.

In the case of particular needs, it is possible to move the speed

connections (with Faston quick-connectors) following the enclosed

table and relative drawing (see Fig. 29).

MOTOR SPEED CABLE COLOR

ENGINE

FACTORY

CONNECTION

ULTRA LOW RED RED

LOW YELLOW

MEDIUM WHITE WHITE

HIGH ORANGE

SUPER HIGH BLACK BLACK

MOTOR NEUTRAL BLUE BLUE

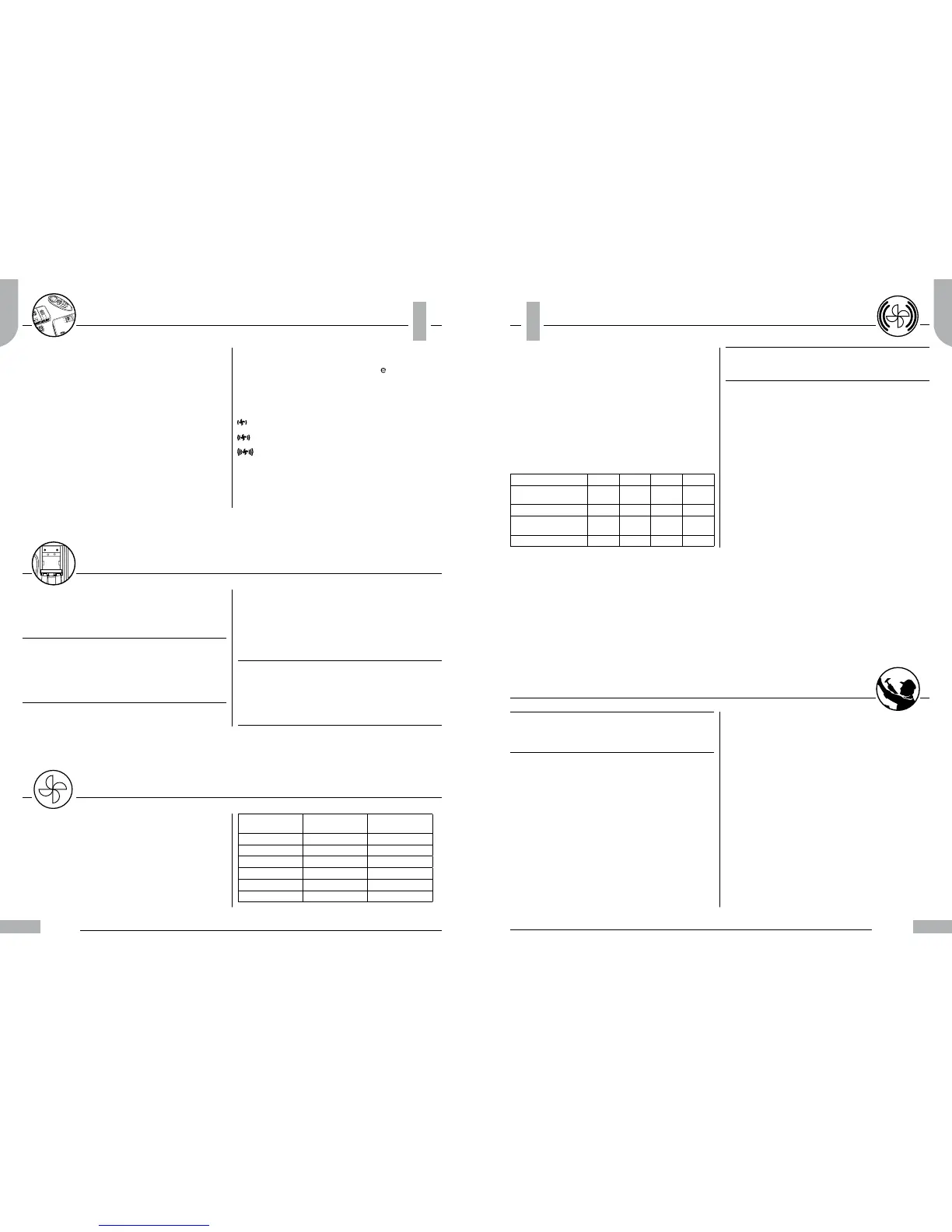

Low Energy Consumption Fan Motor version

The fan coil units of the series 42NE… can ensure a 0% - 100% constant

air ow modulation (and therefore the thermal and refrigerating

capacity) thanks to the Inverter technology combined with the last

generation of high energy-ecient electric motors (EC brushless). This

enables a constant control on the power supplied according to the

room that need to be conditioned. The result is 50% electric energy

saving compared to traditional 3-speed asynchronous motors and a

considerable reduction of acoustic emissions.

The new range of fan coil units 42NE is equipped with 4 Low Energy

Consumption Fan Motors one of which is tangential and 3 centrifugal.

The table below shows the electrical characteristics of the four types of

motors.

NOTE:

The values showed on table are reported only at the Low Energy •

Consumption Fan Motor to they are necessary add the control

input power which correspond about 5W

The fan coil units of the series 42NE are submitted by Carrier to the NTC

control (see attached additional manual) for best regulation of room

temperature.

No further electrical connections are necessary (beside power supply

and communication bus)

for this unit.

All connections between electric components and motor are factory

made.

In the centrifugal units, the inverter regulation board is directly installed

on the motor frame and protected by a metal case.

See g. 42-43.

Due to the lack of space, in the tangential units the regulation board is

installed in the electric panel of the NTC controller.

See g. 41.

42NE E19 E29 E39 E49

MINIMUM SPEED

POWER INPUT (W)

4,5 4,6 6,6 9

CURRENT DRAWN (A) 0,057 0,061 0,076 0,09

MAXIMUM SPEED

POWER INPUT (W)

14,5 14,5 30,1 60,9

CURRENT DRAWN 0,144 0,144 0,271 0,514

Diagnostic warnings

The following alarm situations are indicated:

Defective sensors: the red LED ashes.

Possible causes:

failure or short circuit of internal or remote sensor;•

failure or short circuit of water temperature sensor (optional and only •

on type “A” control).

Incorrect conguration

The yellow LED ashes.

This happens when:

in type “A” control, both centralised seasonal changeover signals “RC •

and RH” are enabled.

Autotest

The autotest function is activated by holding the seasonal changeover

button pressed and at the same time pressing the “

” button three

times within 1 second.

In this way it is possible to check the starting of all fan coils.

The blue and red LEDs will begin to ash.

Each of the various units will be activated for 10 seconds in the following

sequence:

Low fan speed.

Medium fan speed.

High fan speed.

CV Motorized cold-water valve.

HV Motorized hot-water valve, or electric heater (only type “B”

control versions).

Elapsed 1 minute the control ends the test mode.

Electric heater

Maintenance

IMPORTANT:

The following maintenance operations should be carried out by

qualied personnel.

Disconnect the mains power supply prior to any maintenance

operations or prior to handling any internal parts of the unit.

Air lter

Check and make sure the lter is cleaned every two months or more

often if unit is located in a dusty room.

A dirty lter reduces the air ow and unit eciency.

To inspect lter proceed as follows:

switch the unit o;•

loosen the two screws located at the base of the unit and the •

corresponding plates and the corresponding plates or the rear closing

grille (if installed);

lower the two guides and withdraw lter (See g. 38)•

clean the lter gently with soapy water or with a vacuum cleaner;•

reinsert and position the lter in the guides, keeping the •

photocatalytic lter tabs upwards as illustrated (See g. 39)

return the lter guides to their original position (See g. 40)•

tighten the screws and associated plates.•

It is advisable to clean and if necessary replace the air lter before

the winter season.

Condensate draining

During the summer season check that the condensate drain is free from

dust and lint that could clog it, causing condensate water overow.

Heat exchanger coil

At the beginning of any winter and summer season it is advisable to

check that the coil ns are not clogged with dust, lint or other foreign

matter.

Clean the heat exchanger after having removed the supply grille, taking

care not to damage the ns.

Motor

The motor is permanently lubricated.

Therefore no periodical maintenance is required.

Fan Motor

Loading...

Loading...