27

ATTENTION: If the recommendations above are not

followed, any resulting frost damage is not covered by the

guarantee.

The frost protection and electric heater solutions can be

combined. If protection by electric heater is used, do not

switch off the power supply to the unit.

IMPORTANT: The main unit disconnect switch, the

auxiliary heater protection switch as well as the control

circuit switch must always remain closed (to locate the

components, please refer to the wiring diagram).

IMPORTANT: Depending on the climatic conditions in

your area you must do the following when you shut the

unit down in winter:

• Add ethylene glycol with an adequate concentration

to protect the installation up to a temperature of 10 K

below the lowest temperature likely to occur at the

installation site.

• If the unit is not used for an extended period, it is

recommended to drain it, and as a safety precaution

add ethylene glycol to the heat exchanger, using the

water entering purge valve connection.

• At the start of the next season, refill the unit with water

and add an inhibitor.

• For the installation of auxiliary equipment, the instal-

ler must comply with basic regulations, especially for

minimum and maximum flow rates, which must be

between the values listed in the operating limit table

(application data).

• If any heat transfer circuit is emptied for longer than

a month, the complete circuit must be placed under

nitrogen charge to avoid any risk of corrosion by

differential aeration. If the heat transfer fluid does

not comply with Carrier recommendations, nitrogen

must be charged immediately.

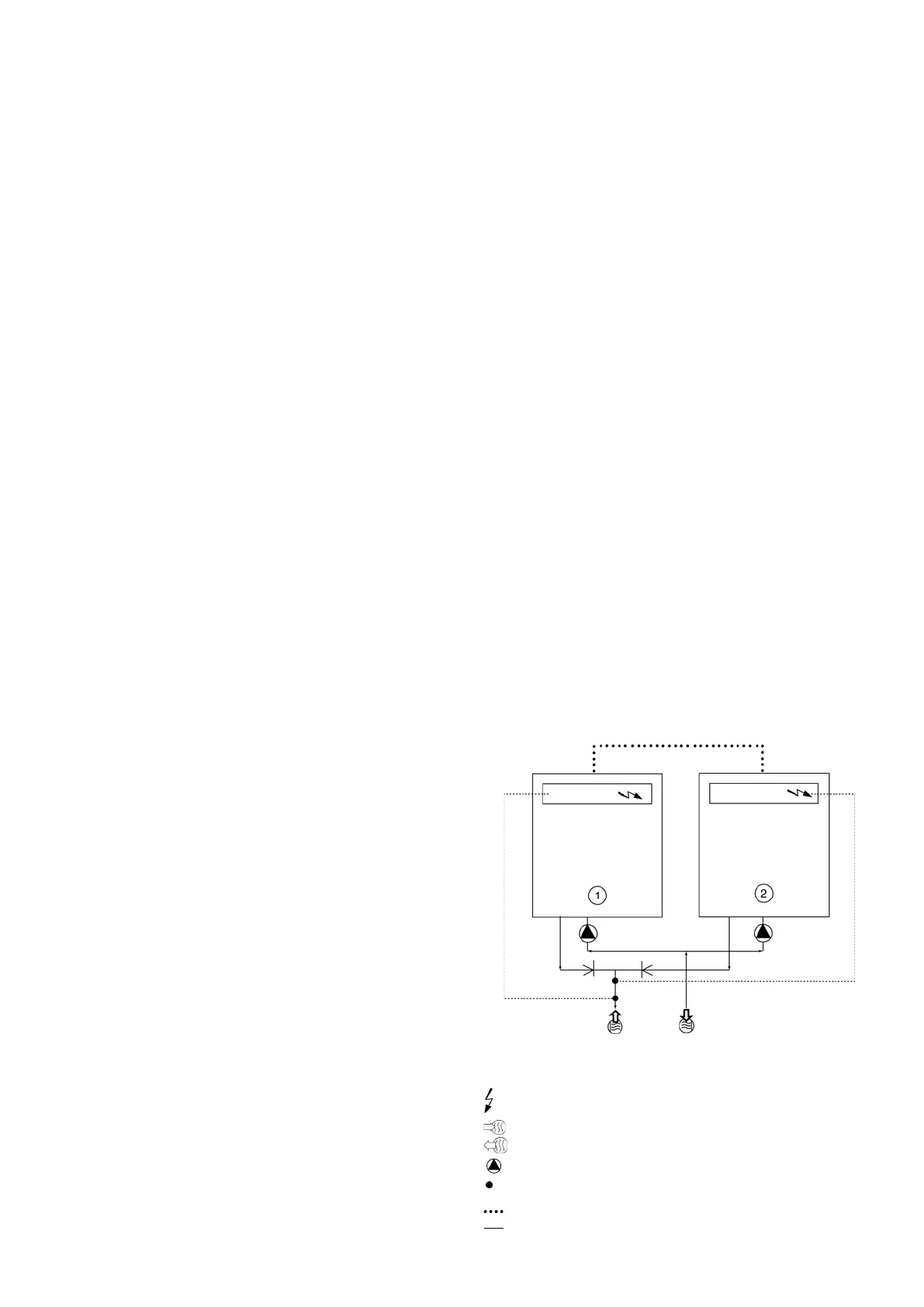

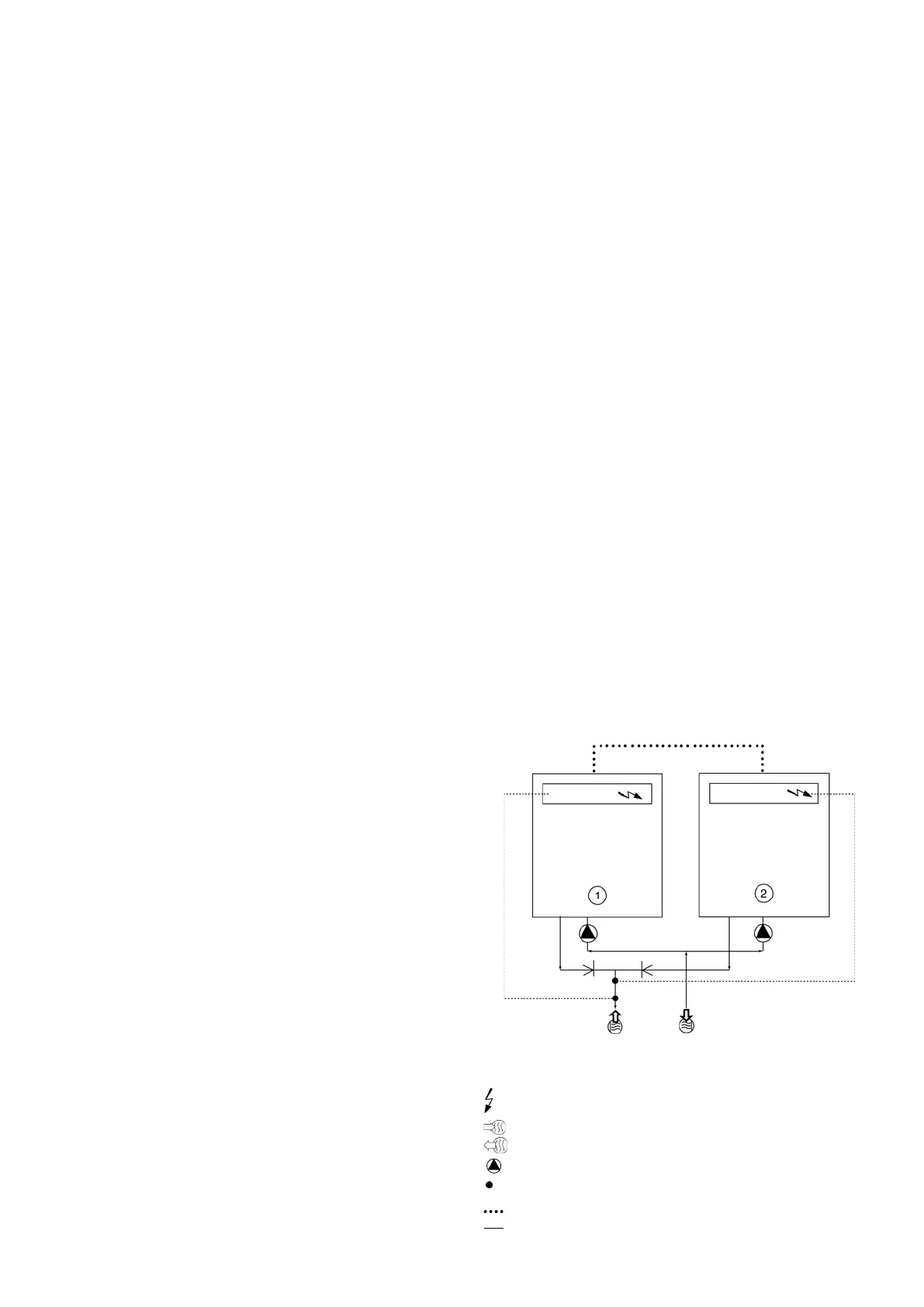

For this type of operation the ‘Twinning’ option must be

ordered.

The units supplied are then equipped with an additional

sensor connected to the electronic board and located in

the control box.

This sensor must be used when master/slave assembly

control at the water outlet is used (it is not required for

entering water control).

The customer must connect the two units via a communi-

cation bus (0.75 mm

2

, twisted and shielded). Consult the

30RB Pro-Dialog Plus control manual for the connection

addresses.

Master/slave operation is only possible, when the units are

installed in parallel. It is not possible, if the units are

installed in series.

All parameters, required for the master/slave function must

be configured using the Service Configuration menu. All

remote controls of the master/slave assembly (start/stop, set

point, load shedding etc.) are controlled by the unit configured

as master and must only be applied to the master unit.

Each unit controls its own water pump. If there is only one

common pump, in cases with variable flow, isolation valves

must be installed on each unit. They will be activated at the

opening and closing by the control of each unit (in this case

the valves are controlled using the dedicated water pump

outputs). See the 30RB Pro-Dialog Plus Control IOM for

a more detailed explanation.

1 Master unit

2 Slave unit

Control boxes of the master and slave units

Water inlet

Water outlet

Water pumps for each unit (included as standard for units with hydronic

module)

Additional sensors for leaving water control, to be connected to channel 1

of the slave boards of each master and slave unit

CCN communication bus

Connection of two additional sensors

Loading...

Loading...