PF4MNB, PF4MNP: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

7

Ground Connections

NOTE: Use UL listed conduit and conduit connectors for connecting

supply wire(s) to unit to obtain proper grounding. Grounding may also

be accomplished by using grounding lugs provided in control box.

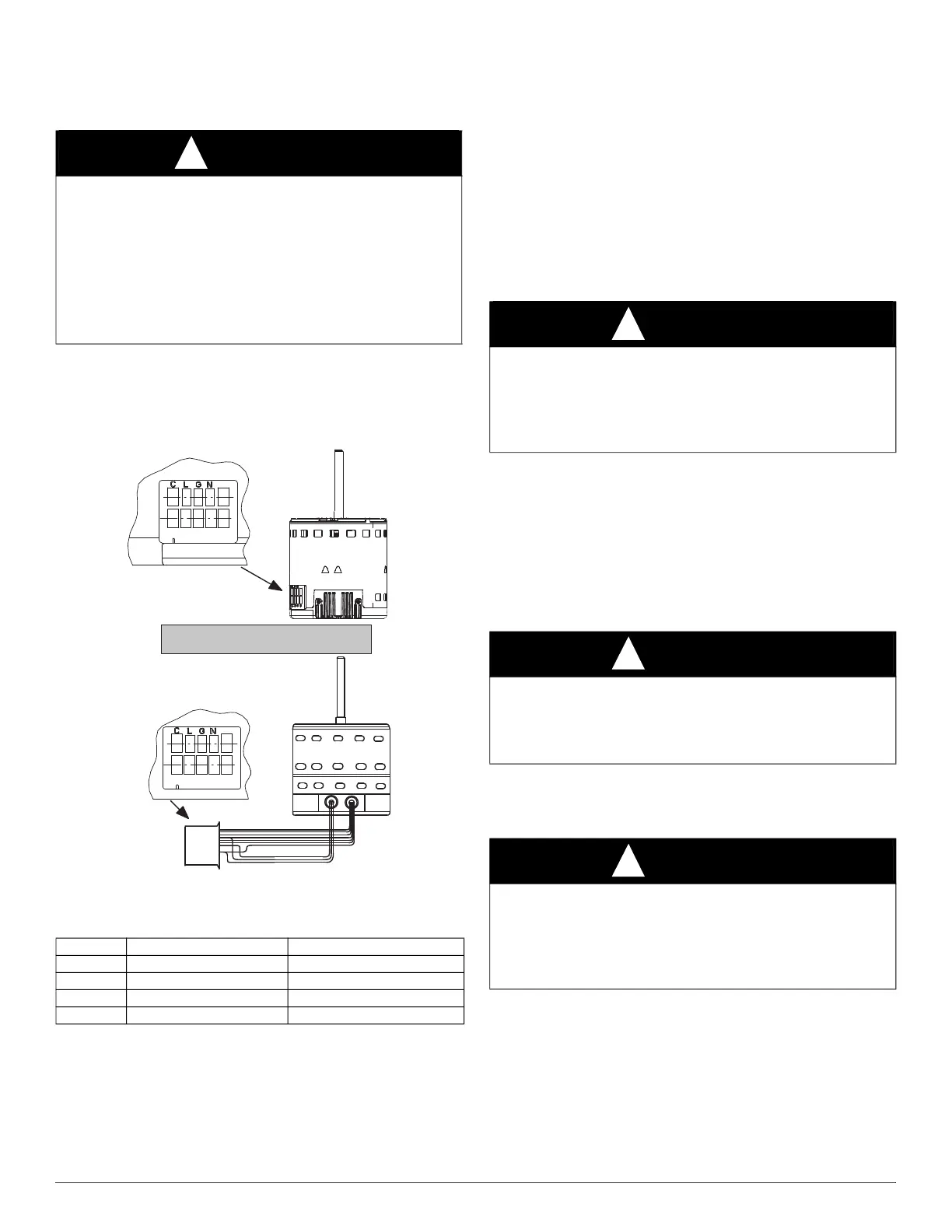

Minimum CFM and Motor Speed Selection

The fan speed selection is done at the motor connector. Units with or

without electric heaters require a minimum CFM. Refer to the unit

wiring label to ensure that the fan speed selected is not lower than the

minimum fan speed indicated.

A11048

Fig. 14 – Motor Speed Selection

† electric heat airflow is same CFM as Tap 3, except 0 sec off delay

‡ high static applications, see airflow tables for max airflow

To change motor speeds disconnect the BLUE fan lead from motor

connector terminal #2 (factory default position) and move to desired

speed-tap; 1, 2, 3, or 5.

Speed-taps 1, 2, and 3 have a 90-second blower off time delay

pre-programmed into the motor. Speed-tap 4 is used for electric heat

only (with 0 second blower time delay) and the WHITE wire should

remain on tap 4. Speed-tap 5 is used for high static applications, but has

a 0 second blower time delay pre-programmed into the motor. See

Airflow Performance tables for actual CFM. Also see Fig. 14 for motor

speed selection location.

NOTE: In low static applications, lower motor speed tap should be used

to reduce possibility of water being blown off coil.

Refrigerant Tubing Connection and

Evacuation

Use accessory tubing package or field-supplied tubing of refrigerant

grade. Suction tube must be insulated. Do not use damaged, dirty, or

contaminated tubing because it may plug refrigerant flow-control

device. ALWAYS evacuate the coil and field-supplied tubing to 500

microns before opening outdoor unit service valves.

Units have sweat suction and liquid tube connections. Make suction tube

connection first.

1. Cut tubing to correct length.

2. Insert tube into sweat connection on unit until it bottoms.

3. Braze connection using silver bearing or non-silver bearing brazing

materials. Do not use solder (materials which melt below 800°F /

427°C). Consult local code requirements.

4. Evacuate coil and tubing system to 500 microns using a deep

vacuum method.

Refrigerant Flow-Control Device

The PF4M units come equipped with a R-410A refrigerant TXV.

Always use outdoor units designed to match indoor fan coil applications.

Condensate Drains

To connect drains, the cap openings must be removed. Use a knife to

start the opening near the tab and using pliers, pull the tab to remove the

disk. Clean the edge of the opening if necessary and install the

condensate line. Finally caulk around the lines where they exit the fitting

to retain the low leak rating of the unit.

Units are equipped with primary and secondary 3/4-in. FPT drain

connections. For proper condensate line installations see Fig. 1 thru

Fig. 5. To prevent property damage and achieve optimum drainage

WARNING

!

ELECTRICAL SHOCK HAZARD

Failure to establish uninterrupted or unbroken ground could result in

personal injury and/or death.

According to NEC, NFPA 70, and local codes, the cabinet must have an

uninterrupted or unbroken ground to minimize personal injury if an

electrical fault should occur. The ground may consist of electrical wire

or metal conduit when installed in accordance with existing electrical

codes. If conduit connection uses reducing washers, a separate ground

wire must be used.

Table 1 – Fan Speed Selection

Tap 1

Low 90 sec off delay

Tap 2

Medium 90 sec off delay

Tap 3

High 90 sec off delay

Tap 4

Electric heat † 0 sec off delay

Tap 5

Max ‡ 0 sec off delay

1 2 3 4 5

Speed Taps may be located on motor,

or on plug close to motor.

CLGN

1 2 3 4 5

CAUTION

!

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product or property damage.

A brazing shield MUST be used when tubing sets are being brazed to

the unit connections to prevent damage to the unit surface and

condensate pan fitting caps.

CAUTION

!

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product or property damage.

Wrap a wet cloth around rear of fitting to prevent damage to TXV and

factory-made joints.

CAUTION

!

PRODUCT OPERATION HAZARD

Failure to follow this caution may result in improper product operation.

If using a TXV in conjunction with a single-phase reciprocating

compressor, a compressor start capacitor and relay are required.

Consult outdoor unit pre-sale literature for start assist kit part number.

Loading...

Loading...