PF4MNB, PF4MNP: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

9

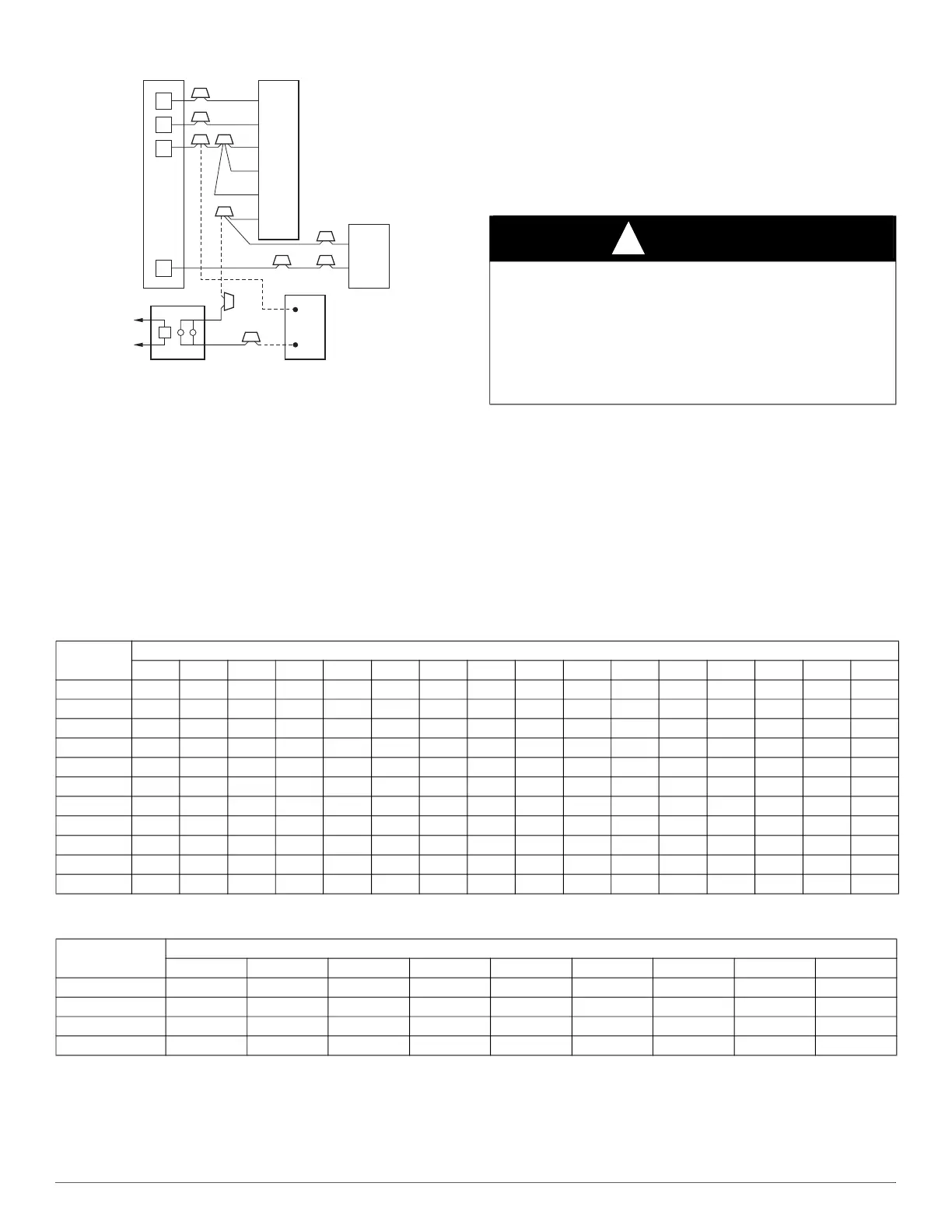

A95295

Fig. 19 – Wiring Layout of Humidifier to Fan Coil

with Electric Heat

Cooling Mode

Thermostat energizes R to G, R to Y, and R to O (heat pump only). G

energizes circuit to indoor blower motor. When G is de-energized, there

is a 90-second delay before fan relay opens.

Heat Pump Heating with Auxiliary Electric Heat

Thermostat energizes R to G, R to Y, and R to W. G energizes circuit to

indoor blower motor. W energizes electric heat relay(s) which completes

circuit to heater element(s). When W is de-energized, electric heat

relay(s) open, turning off heater elements. When G is de-energized there

is a 90-second delay before fan relay opens.

Electric Heat or Emergency Heat Mode

Thermostat closes R to W. W energizes electric heat relay(s) which

completes circuit to heater element(s). Blower motor is energized

through speed tap 4 (white wire). When W is de-energized, electric heat

relay(s) opens.

Start-Up Procedures

Refer to outdoor unit Installation Instructions for system start-up

instructions and refrigerant charging method details.

Care and Maintenance

To continue high performance and minimize possible equipment failure,

it is essential that periodic maintenance be performed on this equipment.

Consult your local dealer as to the proper frequency of maintenance

contract.

The ability to properly perform maintenance on this equipment requires

certain mechanical skills and tools. If you do not possess these, contact

your dealer for maintenance. The only consumer service recommended

or required is filter replacement or cleaning on a monthly basis.

R

G

W

Y

THERMOSTAT

R

G

W

2

W

3

E

C

FAN COIL

(CONTROL)

C

Y

AIR COND.

HUMIDISTAT

FAN HUMIDIFIER

115V

RED

GRY

WHT

WHT

BLU

VIO

BRN

M

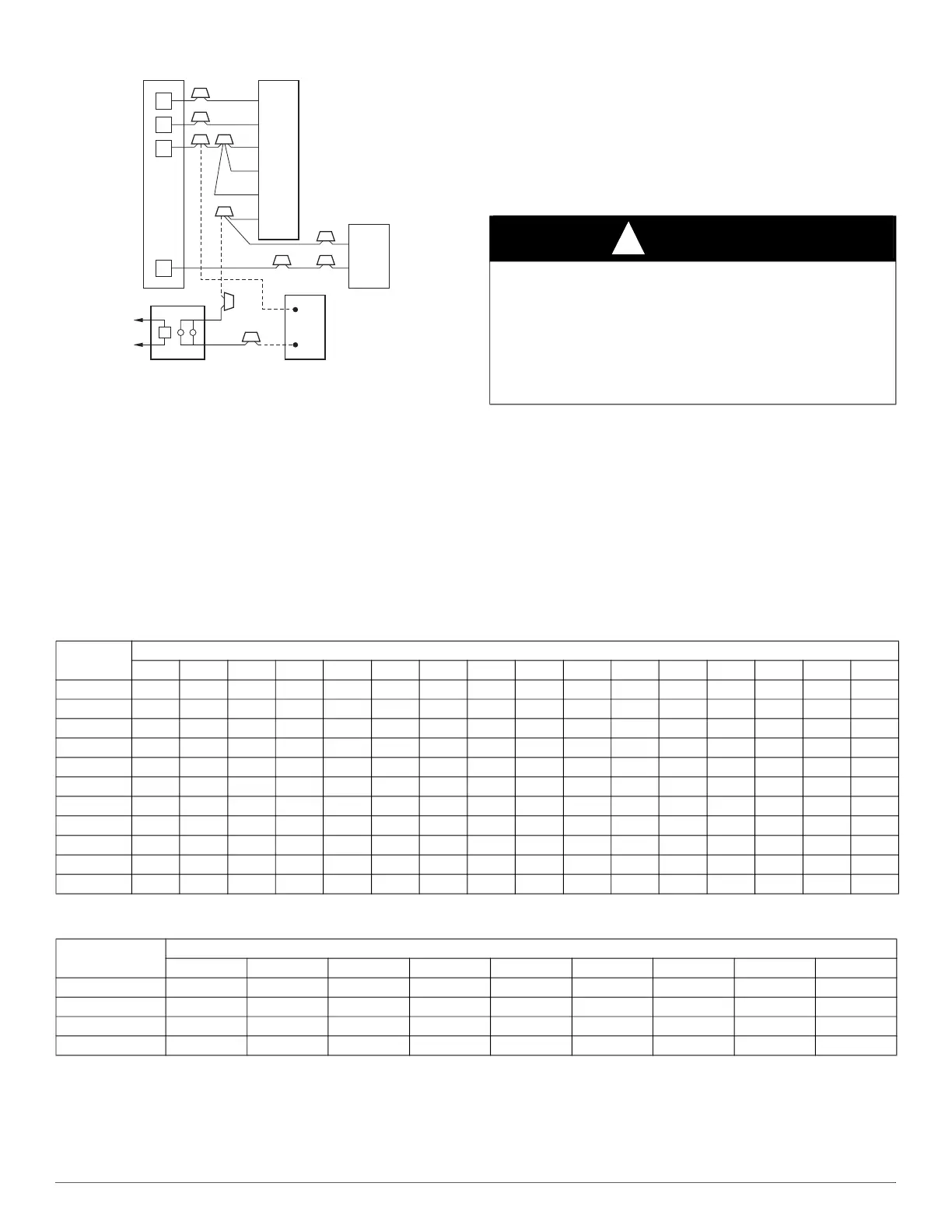

CAUTION

!

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in poor unit performance

and/or product damage.

Never operate unit without a filter. Factory authorized filter kits may be

used when locating the filter inside the unit. For those applications

where access to an internal filter is impractical, a field-supplied filter

must be installed in the return air duct system.

Table 2 – Air Delivery Performance Correction Component Pressure Drop (in. wc) at Indicated Airflow (Dry-to-Wet Coil)

UNIT SIZE

CFM

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

018, 019

0.034 0.049 0.063 - - - - - - - - - - - - - - - - - - - - - - - - - -

024

0.034 0.049 0.063 0.076 0.089 - - - - - - - - - - - - - - - - - - - - - -

025

0.015 0.026 0.038 0.049 0.059 - - - - - - - - - - - - - - - - - - - - - -

030, 031

- - - - - - 0.049 0.059 0.070 0.080 - - - - - - - - - - - - - - - - - -

036

- - - - - - - - - - 0.070 0.080 0.090 0.099 - - - - - - - - - - - - - -

037

- - - - - - - - - - 0.055 0.064 0.073 0.081 - - - - - - - - - - - - - -

042, 043

- - - - - - - - - - - - - - 0.049 0.056 0.063 0.070 - - - - - - - - - -

048

- - - - - - - - - - - - - - - - - - 0.063 0.070 0.076 0.083 0.090 - - - -

049

- - - - - - - - - - - - - - - - - - 0.038 0.043 0.049 0.054 0.059 - - - -

060

- - - - - - - - - - - - - - - - - - - - - - 0.049 0.054 0.059 0.065 0.070

061

- - - - - - - - - - - - - - - - - - - - - - 0.027 0.031 0.035 0.039 0.043

Table 3 – Factory-Installed Filter Static Pressure Drop (in. wc)

SIZE

CFM

400 600 800 1000 1200 1400 1600 1800 2000

018, 019

0.020 0.044 0.075 - - - - - -

024 - 031

- 0.022 0.048 0.072 0.100 - - - -

036-049

- - - 0.051 0.070 0.092 0.120 0.152 -

060, 061

- - - - - - 0.086 0.105 0.130

Loading...

Loading...