15

Installation manual

Fig.5-5

CAUTION

Use the vacuum pump which vacuum level lower than

-0.1MPa and the air discharge capacity above 40L/min.

The outdoor unit is not necessary to vacuum, don’t open the

outdoor unit gas and liquid pipe shut-off valves.

Make sure the vacuum pump could result as -0.1MPa or

below after 2 hrs or above operation. If the pump operated 3

hrs or above could not achieve to -0.1MPa or below, please

check whether water mix or gas leak inside of the pipe.

5.10 Vacuum with vacuum pump

1)

2)

3)

Fig.5-5

5.8 Remove dirt or water in the piping

Make sure there is no any dirt or water before connecting

the piping to the outdoor units.

Wash the piping with high pressure nitrogen, never use

refrigerant of the outdoor unit.

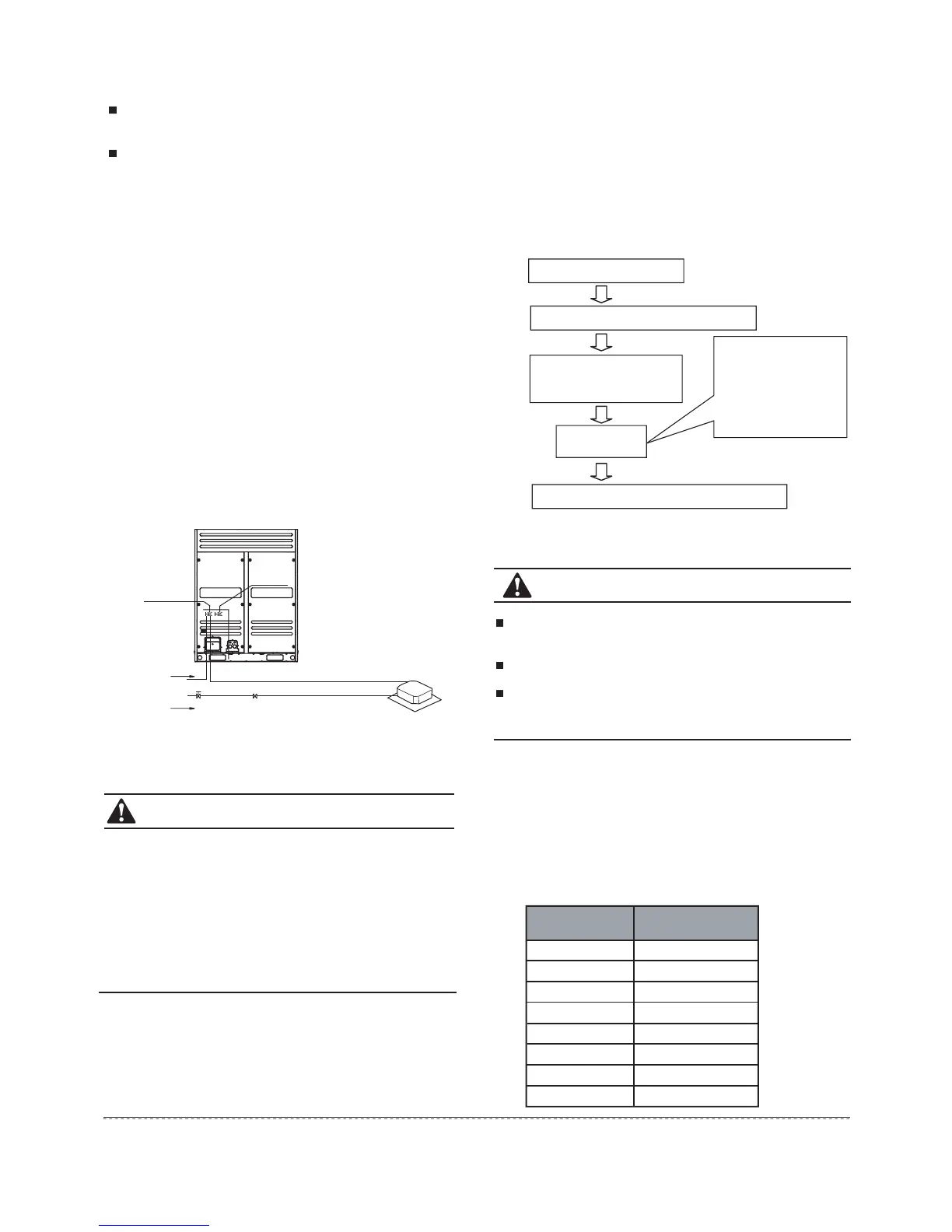

5.9 Gas tight test

Upon set up the indoor unit pipeline, please connect the Hi-

pressure pipe with shut-off valve firstly.

Weld the pipe at the low pressure side to the meter connector.

Use the vacuum pump discharging air inside the liquid side

shut-off valve and meter connecter, until to the -1kgf/

CM2

.

Close the vacuum pump, charge 40kgf/

CM2

nitrogen gas from

the piston of shut-off valve and from the meter connector.

Pressure inside should be maintained at there no less than

24 hrs.

Upon the airtightness test, do a good welding between float

valve and pipe at the low pressure side.

Pressurized nitrogen˄3.9MPa˗40kgf/

CM2

˅is used for

airtightness test.

It is not allow to bring pressure on the float valve directly.

(See Fig. 5-5˅

It is not allow to use oxygen, combustible gas or toxic gas

to conduct the airtightness test.

When welding, please use wet cloth insulating the low

pressure valve for protection.

For avoid the equipment be damaged, the pressure

maintainedtime should not last too long.

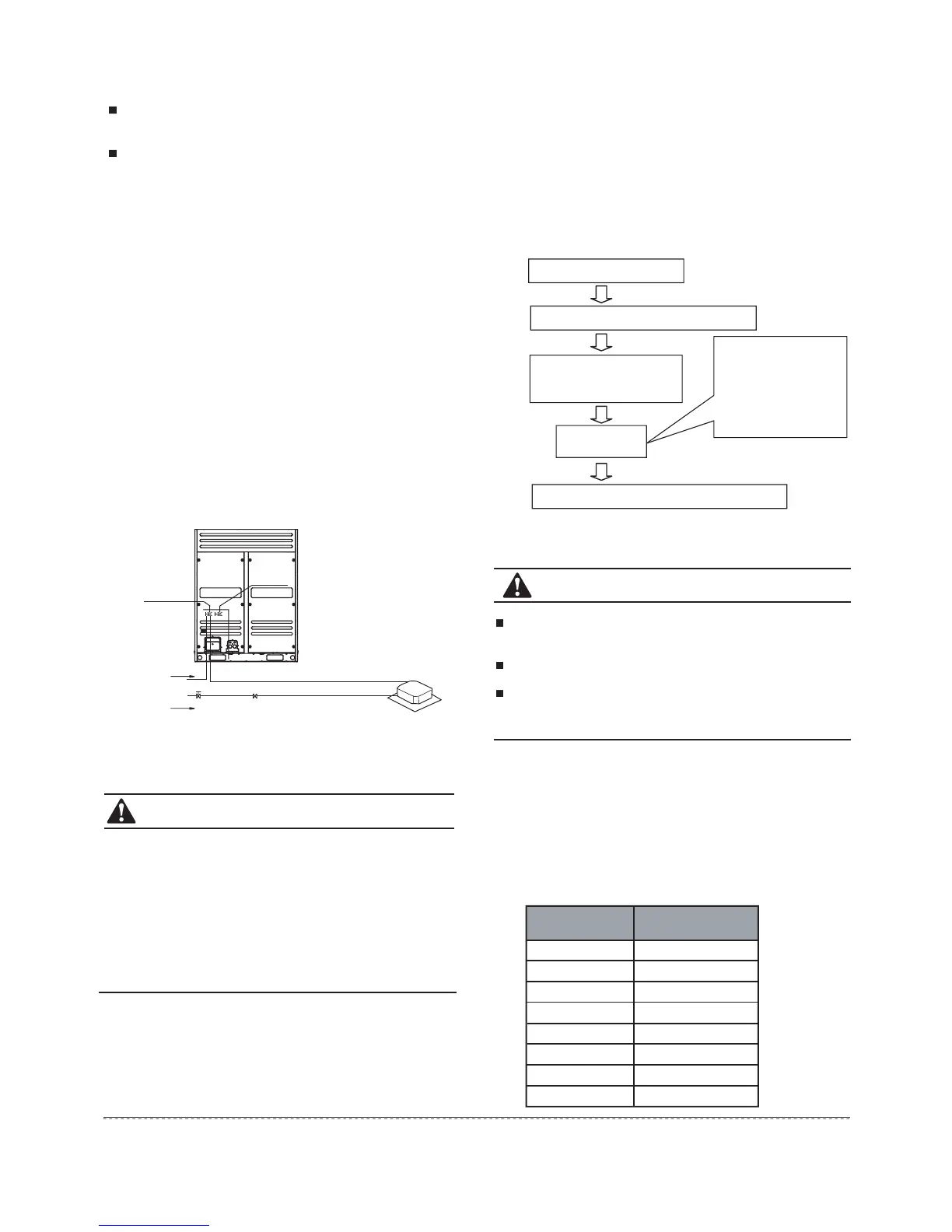

Connect with vacuum pump

Perform the pump (last for 2 hrs or above)

When get the vacuum level

-0.1MPa, the pump should

keep running for 20-60 mins

Shut down the

vaccun pump

Place the vaccum state unused (1 hrs or above)

1. Close-off the valve of

vacuum meter.

2. Cut off the connection

between pressure meter

and vacuum pump.

3. Close the vacuum

pump.

●

●

●

●

●

1)

2)

3)

4)

5)

Outdoor unit

Indoor unit

Nitrogen

Nitrogen

Liquid pipe

Gas pipe

Liquid side of

shut-off valve

Gas side of float valve

Pressure meter connector

CAUTION

5.11 Refrigerant amount to be added

Calculate the added refrigerant according to the diameter and

the length of the liquid side pipe of the outdoor/indoor unit

connection. The refrigerant is R410A.

Pipe size on

liquid side

Refrigerant to

be Added per meter

Φ6.4

Φ9.5

Φ12.7

Φ15.9

Φ19.1

Φ22.2

Φ25.4

Φ28.6

0.022kg

0.057kg

0.110kg

0.170kg

0.260kg

0.360kg

0.520kg

0.680kg

Table.5-10

Don’t mix up the different refrigerants or abuse the tools and

measurements which directly contact with refrigerants.

Don’t adopt refrigerant gas for air vacuuming.

If vacuum level could not get to -0.1MPa, please check whether

resulted by leakage and confirm the leakage site.If no leakage,

please operate the vacuum pump again 1 or 2 hrs.

Loading...

Loading...